Marley MD

Counterflow Cooling Tower

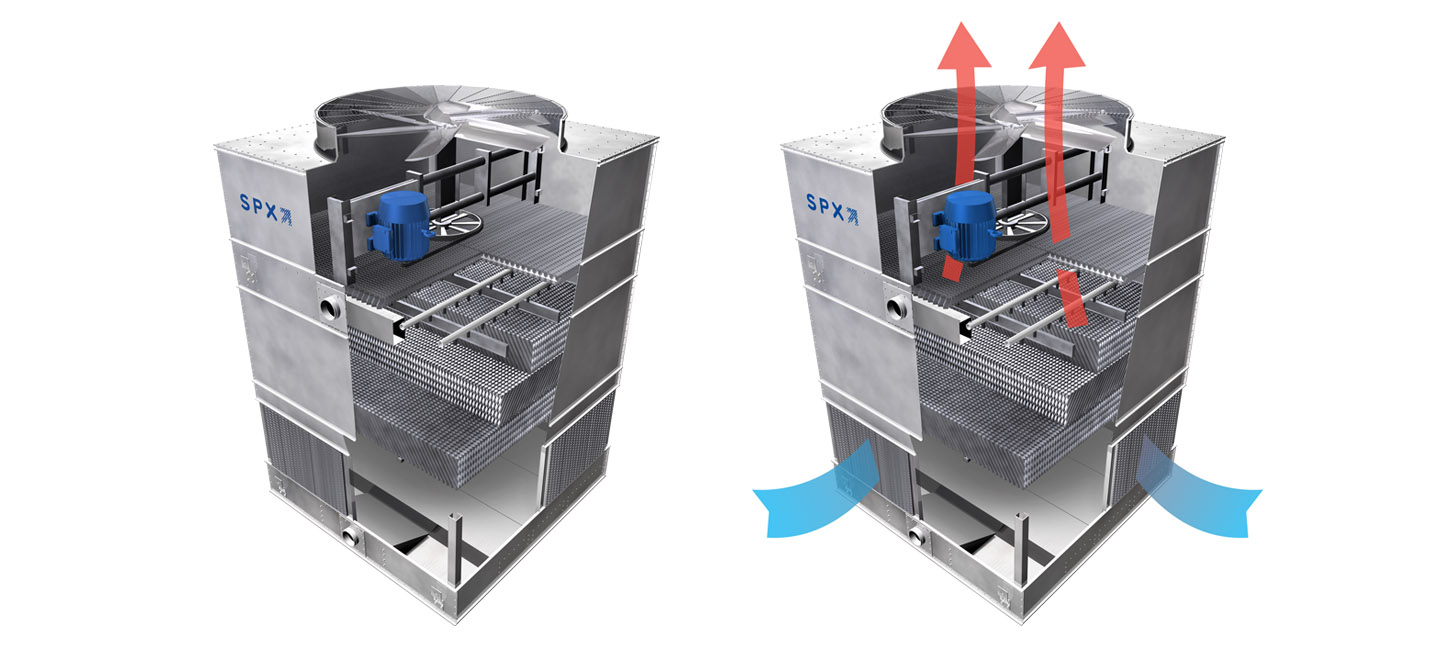

The Marley MD is a factory-assembled, counterflow cooling tower. For many HVAC and light industrial applications, this design requires less plan area and offers greater site placement flexibility than a comparable crossflow cooling tower. A broader box size selection and more design options have expanded the range of the versatile MD product line. New selections with anti-fouling film-type fill expand the MD’s applications to include process water with high solids content.

Back-to-back installation configurations for all models provide even more site placement adaptability. Optional mechanical access platforms are now available, whether factory assembled or field installed, that allow safe access to the mechanical system, water distribution system, fill and drift eliminators. The Marley MD is a CTI-certified, fully rated cooling tower for a wide range of flow and temperature requirements.

Assembly

Brand: Marley

Configuration

Availability: Worldwide

Capacity

(61-515 m3/hr)

Thermal Capacity: 89-756 tons

(391-3323 kW)

Certifications

OSHA Compliant

FM APPROVED

ASHRAE 90.1 compliant

Eurovent certified

Details

Unmatched Reliability

Heavy-duty construction, high-performance design, and our five-year mechanical warranty ensure consistent, fully rated cooling over a wide range of flow and temperature requirements.

Smaller Footprint

Induced-draft counterflow cooling tower design requires less plan area than crossflow cooling towers for many HVAC and light industrial duties. And because the cooling tower’s size typically results in less steel used, its reduced weight requires less support structure.

Low Energy Consumption

Induced-draft counterflow mechanical equipment minimizes the energy consumption by providing a lower fan energy requirement than centrifugal fan counterflow cooling towers.

Ease of Maintenance

SPX Cooling Technologies has worked hard to address the maintenance difficulties long associated with counterflow cooling towers. Our MD cooling tower provides larger access doors, easily removable block fill and other features that simplify maintenance.

Low Sound

The CTI-certified Marley MD cooling tower comes standard with our low-sound fan, suitable for most noise-sensitive situations. Multiple fan and attenuation options are available to meet more stringent sound requirements.

Independently Validated Sound Data

Marley towers are the only package cooling towers tested per CTI ATC-128 test code by third-party CTI-licensed test agents and certified acoustical engineers. MD sound levels are independently verified to meet published sound levels.

Superior Water Management

To address the “splash-out” problem typically found in other manufacturers’ counterflow cooling tower designs, SPX introduces an industry first: a triple-pass inlet louver that conserves water and improves winter operation.

FM Approval

For applications of two or more cells, the MD tower conforms to the FM Approval Standard for cooling towers, Class Number 4930.

High efficiency fan has wide-chord design for maximum efficiency at low fan tip speeds.

Eased inlet fan cylinder ensures full-area, low-turbulent airflow through the cylinder.

Spherical roller bearings are rated at an L10 life of 100,000 hours.

TEFC Fan Motor with a 1.15 service factor, variable torque and special insulation for cooling tower duty extends life cycle.

The MD air movement package including structural support is guaranteed against failure for five years.

WATER DISTRIBUTION SYSTEM

Pressurized spray system distributes water evenly over the fill.

Low-clog polypropylene nozzles deliver precise distribution of water over the fill area.

Marley MC thermoformed PVC film fill assembled into packs for easy removal and cleaning. Low-clog film fill also available for dirty water applications.

Marley XCEL drift eliminators limit drift losses to no more than 0.001% of the design flow rate.

STRUCTURE

Induced-draft counterflow design may require less plan area than crossflow cooling towers typically use.

Steel Construction is heavy mill galvanized steel construction standard. Series 300 stainless steel optional.

Factory assembly ensures efficient field installation.

Triple-pass inlet louvers limit splash-out and eliminate sunlight from entering the cooling tower collection basin.

VALUE-ADDED OPTIONS

Marley System 5 Geareducer drive – Requires no oil changes for five full years, the lowest maintenance requirements in the industry. Fewer oil changes reduce waste stream and environmental impact. Independent tests prove Marley Geareducer is up to 12 dBA quieter than gearboxes used by other cooling tower manufacturers.

Welded stainless steel collection basin – For extra protection, all collection basin parts exposed to the circulating water (including structural members that project into the basin) and all basin options are heavy-gauge 300 series stainless steel.

Mechanical access door platform – The steel structure and bar grating are attached to and supported by the cooling tower, allowing access to the mechanical system, drift eliminators, distribution system and fill. Available factory assembled or for field installation.

Ultra Quiet fan – Wide-chord acoustic geometry fan maximizes efficiency while significantly reducing sound levels. Fan is constructed of lightweight and durable, corrosion and fire resistant marine grade aluminum.

Sound attenuation – Splash attenuation media installed in the collection basin reduces falling water noise effectively and economically. Fan outlet attenuation is also available.

Low-clog film fill – This option provides a higher degree of clog resistance for dirty water applications.

Basin sweeper piping – Factory-installed sweeper piping helps to limit dirt and debris buildup in the collection basin, augmenting system filtration.

Control systems – Range in sophistication from standard fan starters and disconnects to Programmable Logic Controllers that work in conjunction with your building or process system.

Variable speed drive – Provides the ultimate in temperature control, energy management, sound control and mechanical equipment longevity.

Solid state water level control package – Monitors basin water level. Optional configurations include makeup, high water level alarm, low water level alarm, high- and low-level cutoffs, and electric basin heater cutoff.

Electric basin heater – A stainless steel electric immersion heater employs a magnetic contactor and solid-state circuit board to help prevent freezing during cold weather.

Thank you for your recent purchase from SPX Cooling Technologies, Inc. We appreciate your business and look forward to serving you in the future.

Benefits of Registering Your SPX Product:

YOU’RE WARRANTED! Your product installation is verified and warranty is activated.

YOU’RE NOTIFIED! You receive immediate notification of important product information and service alerts.

YOU’RE INCLUDED! You receive invitations to exclusive educational programming and events, including School of Cool® tower maintenance workshops.

WE HEAR YOU! Your opinions about our products, services, technical support and programming are requested in voice-of-customer surveys.

SPX Cooling Technologies’ limited warranty terms will apply. For full details of your warranty coverage, please see the warranty certificate included with your product.

Complete the form below to register your product. Please make sure the information provided is accurate – all fields are required in order to register your product.