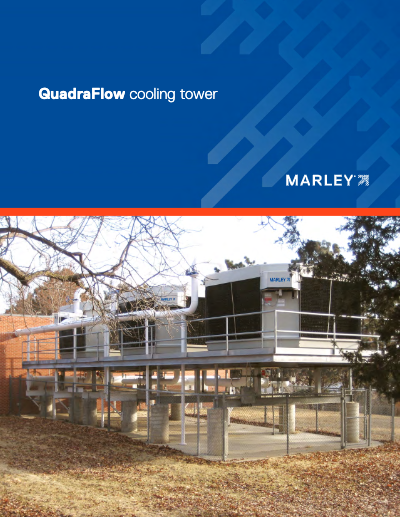

Marley QuadraFlow

Crossflow-Kühlturm

Produktdetails:

Verfügbarkeit: Weltweit

GPM-Bereich: 387-3141

Tons: 129-1047

CTI-zertifiziert

129 – 1047 tons per cell

ASHRAE 90.1-konform

OSHA-konform

Integral louvers for zero-water splashout and superior winter operation

5 year warranty

Was ist ein Kühlturm?

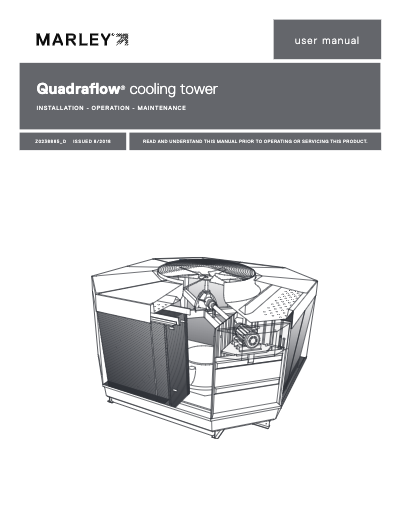

Langlebige Konstruktion

The QuadraFlow cooling tower is built with corrosion-proof materials for reliability in severe operating environments. It is warranted for five full years, which includes the fill, mechanical equipment, and structure.

Niedrige Betriebskosten

Marley’s high-efficiency fill and fans, gravity-flow water distribution, and efficient Geareducer® work together to offer maximum cooling with minimum power use.

Ganzjahresleistung

Performs as specified in the heat of summer — responds well to energy-management techniques in the spring and autumn — operates virtually ice-free in the dead of winter — and offers simple maintenance all year long.

Geringer Wartungsaufwand

Induced-draft adjustable-pitch fan

Marley System 5 Geareducer

Stainless steel free floating driveshaft

TEFC, 1.15 service factor, horizontal-shaft motor and inert construction materials.

Geareducer oil changes are not required for five full years — the lowest maintenance requirements in the industry.

Wasserverteilungssystem

Gravity flow distribution system— easy, non-restrictive maintenance.

Basin covers are standard.

Marley Spiral Target polypropylene nozzles.

Marley MX thermoformed PVC film fill— suspended from structural stainless steel tubing.

Integral eliminators and louvers keep circulating water confined to fill, even at low air rates.

Struktur

Crossflow configuration— easier and safer to maintain.

FRP and 300 series stainless steel— corrosion proof construction.

Four air inlet faces— minimizes recirculation.

Supporting steel— simplifies foundation requirements.

Quality Parts

High Efficiency Axial Fan— Adjustable-pitch fan blades permit maximum utilization of rated horsepower and allows field adjustments to optimize tower performance.

System 5 Geareducer— The Geareducer option requires no oil changes for five full years — the lowest maintenance requirements in the industry. Reduced waste stream and environmental impact. Independent testing has proven a Marley Geareducer is up to 4 dBA quieter than the gearboxes used by most other cooling tower manufacturers.

Fan Motor— TEFC 1.15 service factor, horizontal-shaft motor designed to Marley specifications for cooling tower duty. Specially insulated for humid cooling tower service.

Five-Year Mechanical Warranty— Five-year total mechanical equipment warranty including mechanical equipment support, plus our exclusive 5-year maintenance-free System 5 Geareducer.

Popular Options

Inlet Water Bypass— provision for total water bypass directly into the cooling tower collection basin during cold weather operation.

Hoistable Steel Grillage— allows assembling cooling tower at grade on temporary supports and hoisting into final location.

Fire Retardant FRP— flame spread rating of 25 or less per ASTM E-84.

Control Systems— ranging in sophistication from standard fan starters and disconnects to Programmable Logic Controllers that work in conjunction with your building or process system.

Variable Speed Drive— the ultimate in temperature control, energy management, and mechanical equipment longevity.

Electric Basin Heater Package— maintains collection basin water temperatures between 40°F and 45°F during tower shutdown.

Vibration Limit Switch— shuts down the fan motor if excessive vibration occurs.

Solid State Water Level Control Package— monitor basin water level with solenoid-valve water makeup. Configurations include makeup along with high and low water level alarm and cutoff and electric basin heater cutoff.

Magnetrol® Electric Float Switch— monitor basin water level with solenoid-valve water makeup.

Vielen Dank für Ihren kürzlichen Kauf bei SPX Cooling Technologies, Inc. Wir schätzen Ihr Geschäft und freuen uns darauf, Sie in Zukunft zu bedienen.

Vorteile der Registrierung Ihres SPX-Produkts:

SIE HABEN GARANTIE! Die Installation Ihres Produkts wird überprüft und die Garantie wird aktiviert.

SIE SIND BENACHRICHTIGT! Sie erhalten umgehend Benachrichtigungen über wichtige Produktinformationen und Servicewarnungen.

SIE SIND INKLUSIVE! Sie erhalten Einladungen zu exklusiven Bildungsprogrammen und Veranstaltungen, einschließlich Workshops zur Turmwartung der School of Cool®.

WIR HÖREN DICH! Ihre Meinung zu unseren Produkten, Dienstleistungen, technischem Support und Programmierung wird in Voice-of-Customer-Umfragen abgefragt.

Es gelten die eingeschränkten Garantiebedingungen von SPX Cooling Technologies. Ausführliche Informationen zu Ihrer Garantieabdeckung finden Sie im Garantiezertifikat, das Ihrem Produkt beiliegt.

Füllen Sie das untenstehende Formular aus, um Ihr Produkt zu registrieren. Bitte stellen Sie sicher, dass die bereitgestellten Informationen korrekt sind – Alle Felder sind erforderlich, um Ihr Produkt zu registrieren.