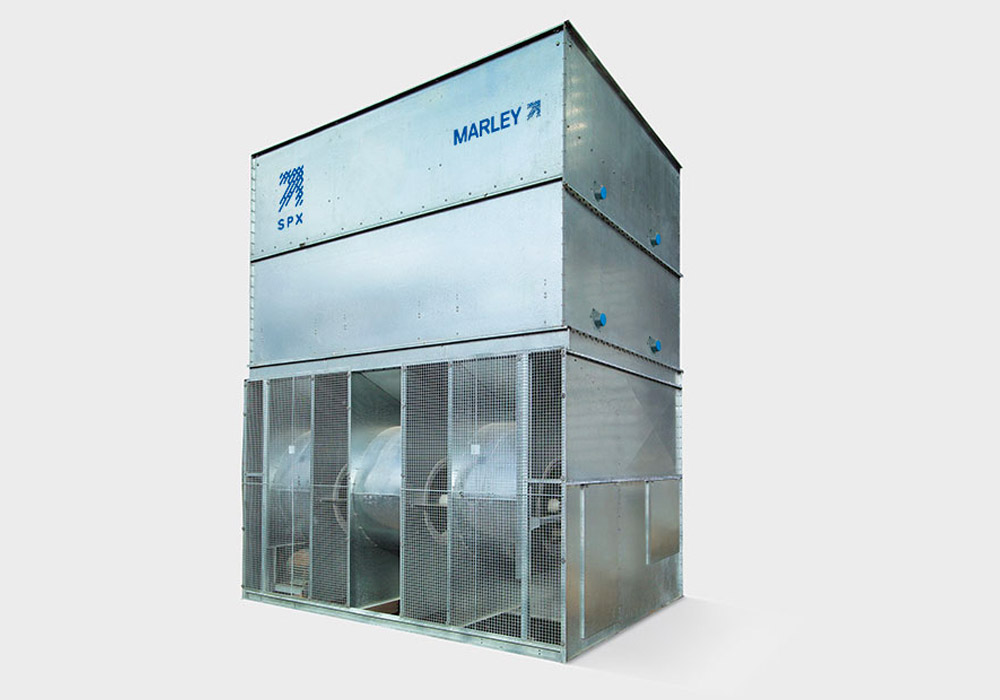

Enfriador de líquido Marley MC

Enfriador de fluido evaporativo

Detalles de producto:

Forced Draft Counterflow Closed Circuit Fluid Cooler

Disponibilidad: Mundial

Capacidad Térmica: 10 – 186 tons (44 – 818 kW) per cell

Rango de flujo: 30 – 860 gpm (7 – 195 m3/hr) per cell

External static pressure capability

Centrifugal fan – high fan energy use

Not recommended for outdoor installations

Cumple con OSHA

Unlike most forced draft fluid coolers, the Marley MC Fluid Cooler utilizes large access doors for easy entry and exit. In addition this configuration provides easy access to the motors and fans from grade.

Silencioso por diseño

All Marley MC Fluid Coolers are designed for low sound levels by utilizing centrifugal fans and a fully contained water splash zone. In addition, For those applications where sound is more of a concern than typical, consider air inlet or outlet attenuation for the ultimate in quiet tower operation.

Construcción de larga duración

Rugged G235 heavy mill galvanized steel (G600 in Europe/Z600 China) is standard with S300 series stainless steel as an optional upgrade to part or the entire tower structure. ISO certified plants assure quality factory-assembly.

MC Steel Fluid Cooler use heavy-mill galvanized steel or 300 series stainless steel for high-performance under any operating conditions.

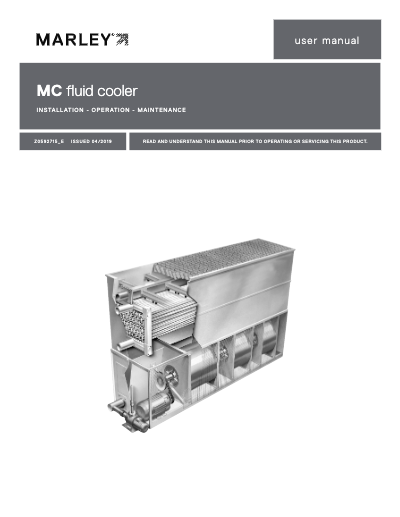

Alto rendimiento por dentro y por fuera

Los ventiladores centrífugos curvos hacia adelante de bajo ruido superan la presión estática impuesta por los conductos externos para un funcionamiento interior silencioso.

El área de agua con zona de caída de salpicaduras completamente cerrada garantiza un bajo nivel de ruido

El sistema de movimiento de aire es accionado por correas mediante correas de cuña dimensionadas para el 150 por ciento de la potencia nominal.

El sistema de distribución de agua incluye tuberías subsidiarias laterales de PVC y boquillas de polipropileno de baja obstrucción.

La baja resistencia del aire mantiene el consumo de energía al mínimo

Atenuadores de sonido clasificados y probados en diseño de fábrica disponibles para entrada y descarga de aire

What every premium installation demands:

Low energy consumption: fluid cooling equipment minimizes the energy consumption of the entire system because it provides lower operating temperatures — saving money while conserving natural resources.

Low noise: centrifugal fans, a fully-enclosed falling water area and optional sound attenuation create one of the quietest fluid cooler configurations on the market.

Smaller footprint: forced-draft counterflow design requires considerably less plan area than crossflow towers.

Ease of maintenance: an extra large entry panel makes the interior of the unit easy to access for service and maintenance. For even greater access, the motor and drive are located outside the plenum area near the grade.