Marley® MH-Flüssigkeitskühler

Verdunstungsflüssigkeitskühler

Produkt Einzelheiten:

Hybrid-Flüssigkeitskühler mit Saugzug und Querstromfüllung/Spulenkühlung

Verfügbarkeit: Weltweit

Thermische Kapazität: 34 – 812 Tonnen (150 – 3570 kW) pro Zelle

Durchflussbereich: 31 – 7330 gpm (7 – 1665 m3/h)

Branchenführende Leistung pro Stellfläche

Höchste Effizienz seiner Klasse

Kupferspulen für alle Modelle verfügbar

CTI-zertifiziert

ASHRAE 90.1-konform

OSHA-konform

Eurovent-zertifiziert

FM-geprüfte Optionen

Der Marley MH Element™ Flüssigkeitskühler mit dem Zusatz von Kupferspulen bietet die höchste Effizienz pro Stellfläche

Hybrides Design

Durch die Verwendung einer Kombination aus Füllmedien und Primärspulen bietet der MH-Flüssigkeitskühler eine deutlich verbesserte Leistung im Vergleich zu herkömmlichen Kühlern mit geschlossenem Kreislauf.

- Die Prozessflüssigkeit wird intern durch die Spule gepumpt

- Die Wärme wird von der Prozessflüssigkeit auf das Umlaufwasser übertragen, wenn es über die Außenseite der Spulenrohre fließt.

- Das erwärmte Umlaufwasser wird vom Sammelbecken in das Schwerkraftverteilbecken gepumpt.

- Ein kleiner Teil des umlaufenden Wassers wird gleichmäßig über das Füllmedium und die Spule verteilt und verdampft, wodurch die Wärme effizient an die Atmosphäre abgegeben wird.

Die richtige Entscheidung

Der Marley MH Fluid Cooler ist eines der energieeffizientesten geschlossenen Kreislaufsysteme auf dem Markt und eine kluge Wahl für geschlossene Kreisläufe in der Industrie und für HLK-Anwendungen.

- Neu! Kupferspulenmodelle: Rüsten Sie jedes beliebige Marley MH Fluid Cooler-Modell auf das MH Element mit Kupferspulen auf. Der MH Element Fluid Cooler bietet überlegene Korrosionsbeständigkeit, verbesserte Wärmeübertragung, reduziertes Betriebsgewicht und zahlreiche weitere Vorteile. Weitere Informationen finden Sie auf der Registerkarte MH Element Fluid Cooler.

- Maximale Effizienz: Hybriddesign und hocheffiziente Komponenten sorgen für eine konstante, zuverlässige Kühlung bei geringer Eingangsleistung.

- Platzsparende Stellfläche: Dank einer höheren Kapazität pro Stellfläche als herkömmliche geschlossene Kreislaufkonstruktionen eignet sich der MH-Flüssigkeitskühler hervorragend für Anwendungen mit Platzbeschränkungen.

- Unübertroffene Zuverlässigkeit: Die robuste Konstruktion mit 5-jähriger mechanischer Garantie sorgt dafür, dass Ihr Prozess Jahr für Jahr reibungslos läuft.

- Zertifizierte Leistung: Die Wärmekapazitäten der Standardmodelle werden vom Cooling Technology Institute unabhängig für die Leistung mit Wasser, Ethylenglykollösungen und Propylenglykollösungen zertifiziert.

- Geräuscharmer Betrieb: Der MH Fluid Cooler ist standardmäßig mit geräuscharmen Lüftern ausgestattet und eignet sich für viele geräuschempfindliche Situationen. Um strengere Schallanforderungen zu erfüllen, sind außerdem mehrere Lüfter- und Dämpfungsoptionen verfügbar.

- Optionale Trockenfähigkeit: Für den Teillast-Trockenbetrieb bei kalten Umgebungsbedingungen sind Modelle mit einer optionalen Spule mit erweiterter Oberfläche erhältlich.

Der neue Marley MH Element Fluid Cooler bietet die gleichen Vorteile, die Sie vom MH Fluid Cooler erwarten können, verbessert jedoch die Wärmeleistung bei geringerem Platzbedarf und geringerem Gewicht. Im Vergleich zu herkömmlichen feuerverzinkten (HDG) Spulenflüssigkeitskühlern bietet das MH Element:

- 15-30% mehr Wärmekapazität, die höchste pro Stellfläche unter allen führenden Flüssigkeitskühlern

- 20% leichterer Turm pro Stellfläche

- 35% weniger Flüssigkeitsvolumen

- 35% weniger Lüfterleistung

Darüber hinaus enthalten die Wärmeübertragungsspulen des MH-Elements Kupfer, das eine siebenmal höhere Wärmeleitfähigkeit als herkömmlicher HDG-Stahl bietet.

Der MH Element Fluid Cooler reduziert den Wartungsaufwand durch die bakteriostatischen Eigenschaften der Kupferspulen, die das Risiko von Verkalkung und Verschmutzung stark einschränken, eine hervorragende Korrosionsbeständigkeit bieten und eine lange Lebensdauer der Geräte ermöglichen. Zusätzliche Nachhaltigkeitsbemühungen werden durch die Recyclingfähigkeit der Kupferspulen mit hohem Restwert unterstützt. Die robuste Konstruktion mit der fünfjährigen mechanischen Garantie von SPX Cooling Technologies sorgt dafür, dass die Prozesse Jahr für Jahr reibungslos laufen.

Die Techniker von SPX führten umfangreiche Labor- und Feldtests durch, um die Leistung der gesamten MH Element-Produktpalette zu optimieren, einschließlich Spulenreihenkonfiguration, Spulendesign, Füllhöhe, Komponenten und Baumaterialien.

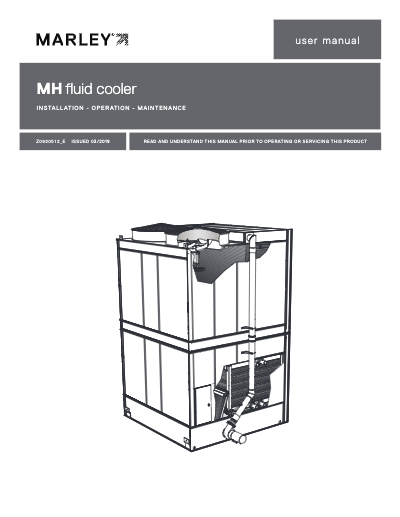

Vielen Dank für Ihren kürzlichen Kauf bei SPX Cooling Technologies, Inc. Wir schätzen Ihr Geschäft und freuen uns darauf, Sie in Zukunft zu bedienen.

Vorteile der Registrierung Ihres SPX-Produkts:

SIE HABEN GARANTIE! Die Installation Ihres Produkts wird überprüft und die Garantie wird aktiviert.

SIE SIND BENACHRICHTIGT! Sie erhalten umgehend Benachrichtigungen über wichtige Produktinformationen und Servicewarnungen.

SIE SIND INKLUSIVE! Sie erhalten Einladungen zu exklusiven Bildungsprogrammen und Veranstaltungen, einschließlich Workshops zur Turmwartung der School of Cool®.

WIR HÖREN DICH! Ihre Meinung zu unseren Produkten, Dienstleistungen, technischem Support und Programmierung wird in Voice-of-Customer-Umfragen abgefragt.

Es gelten die eingeschränkten Garantiebedingungen von SPX Cooling Technologies. Ausführliche Informationen zu Ihrer Garantieabdeckung finden Sie im Garantiezertifikat, das Ihrem Produkt beiliegt.

Füllen Sie das untenstehende Formular aus, um Ihr Produkt zu registrieren. Bitte stellen Sie sicher, dass die bereitgestellten Informationen korrekt sind – Alle Felder sind erforderlich, um Ihr Produkt zu registrieren.