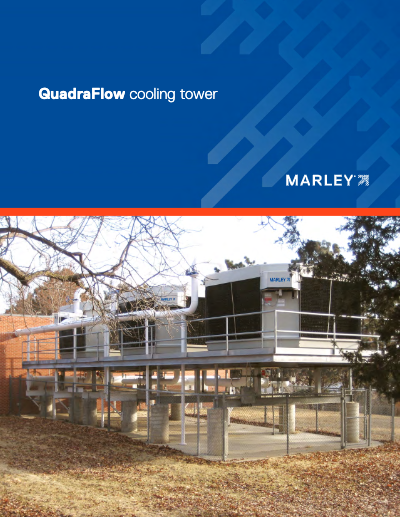

Marley QuadraFlow

Tour de refroidissement à flux transversal

Détails du produit:

Disponibilité: Mondial

Plage de gal/min : 387-3141

Tons: 129-1047

Certifié CTI

129 – 1047 tons per cell

Conforme à la norme ASHRAE 90.1

Conforme à l'OSHA

Integral louvers for zero-water splashout and superior winter operation

5 year warranty

Qu'est-ce qu'une tour de refroidissement ?

Construction longue durée

The QuadraFlow cooling tower is built with corrosion-proof materials for reliability in severe operating environments. It is warranted for five full years, which includes the fill, mechanical equipment, and structure.

Faibles coûts d'exploitation

Marley’s high-efficiency fill and fans, gravity-flow water distribution, and efficient Geareducer® work together to offer maximum cooling with minimum power use.

Performances toutes saisons

Performs as specified in the heat of summer — responds well to energy-management techniques in the spring and autumn — operates virtually ice-free in the dead of winter — and offers simple maintenance all year long.

Faible entretien

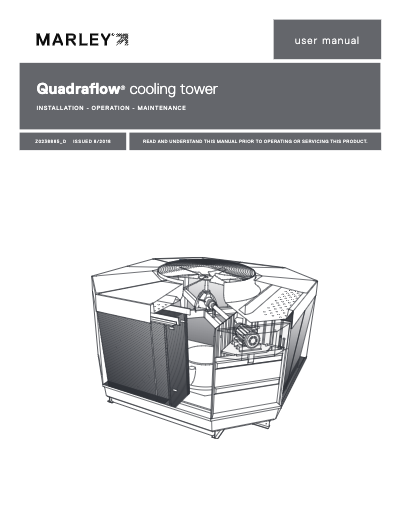

Induced-draft adjustable-pitch fan

Réducteur à engrenages Marley System 5

Stainless steel free floating driveshaft

TEFC, 1.15 service factor, horizontal-shaft motor and inert construction materials.

Geareducer oil changes are not required for five full years — the lowest maintenance requirements in the industry.

Système de distribution d'eau

Gravity flow distribution system— easy, non-restrictive maintenance.

Basin covers are standard.

Marley Spiral Target polypropylene nozzles.

Marley MX thermoformed PVC film fill— suspended from structural stainless steel tubing.

Integral eliminators and louvers keep circulating water confined to fill, even at low air rates.

Structure

Crossflow configuration— easier and safer to maintain.

FRP and 300 series stainless steel— corrosion proof construction.

Four air inlet faces— minimizes recirculation.

Supporting steel— simplifies foundation requirements.

Quality Parts

High Efficiency Axial Fan— Adjustable-pitch fan blades permit maximum utilization of rated horsepower and allows field adjustments to optimize tower performance.

System 5 Geareducer— The Geareducer option requires no oil changes for five full years — the lowest maintenance requirements in the industry. Reduced waste stream and environmental impact. Independent testing has proven a Marley Geareducer is up to 4 dBA quieter than the gearboxes used by most other cooling tower manufacturers.

Fan Motor— TEFC 1.15 service factor, horizontal-shaft motor designed to Marley specifications for cooling tower duty. Specially insulated for humid cooling tower service.

Five-Year Mechanical Warranty— Five-year total mechanical equipment warranty including mechanical equipment support, plus our exclusive 5-year maintenance-free System 5 Geareducer.

Popular Options

Inlet Water Bypass— provision for total water bypass directly into the cooling tower collection basin during cold weather operation.

Hoistable Steel Grillage— allows assembling cooling tower at grade on temporary supports and hoisting into final location.

Fire Retardant FRP— flame spread rating of 25 or less per ASTM E-84.

Control Systems— ranging in sophistication from standard fan starters and disconnects to Programmable Logic Controllers that work in conjunction with your building or process system.

Variable Speed Drive— the ultimate in temperature control, energy management, and mechanical equipment longevity.

Electric Basin Heater Package— maintains collection basin water temperatures between 40°F and 45°F during tower shutdown.

Vibration Limit Switch— shuts down the fan motor if excessive vibration occurs.

Solid State Water Level Control Package— monitor basin water level with solenoid-valve water makeup. Configurations include makeup along with high and low water level alarm and cutoff and electric basin heater cutoff.

Magnetrol® Electric Float Switch— monitor basin water level with solenoid-valve water makeup.

Merci pour votre récent achat auprès de SPX Cooling Technologies, Inc. Nous apprécions votre confiance et sommes impatients de vous servir à l'avenir.

Avantages de l'enregistrement de votre produit SPX :

VOUS ÊTES GARANTI ! L'installation de votre produit est vérifiée et la garantie est activée.

VOUS ÊTES AVERTI ! Vous recevez une notification immédiate des informations importantes sur le produit et des alertes de service.

VOUS ÊTES INCLUS ! Vous recevez des invitations à des programmes et événements éducatifs exclusifs, notamment des ateliers de maintenance des tours School of Cool®.

NOUS VOUS ENTENDONS! Vos opinions sur nos produits, services, support technique et programmation sont demandées dans des enquêtes vocales auprès des clients.

Les conditions de garantie limitée de SPX Cooling Technologies s'appliqueront. Pour plus de détails sur votre couverture de garantie, veuillez consulter le certificat de garantie inclus avec votre produit.

Remplissez le formulaire ci-dessous pour enregistrer votre produit. Veuillez vous assurer que les informations fournies sont exactes – tous les champs sont obligatoires pour enregistrer votre produit.