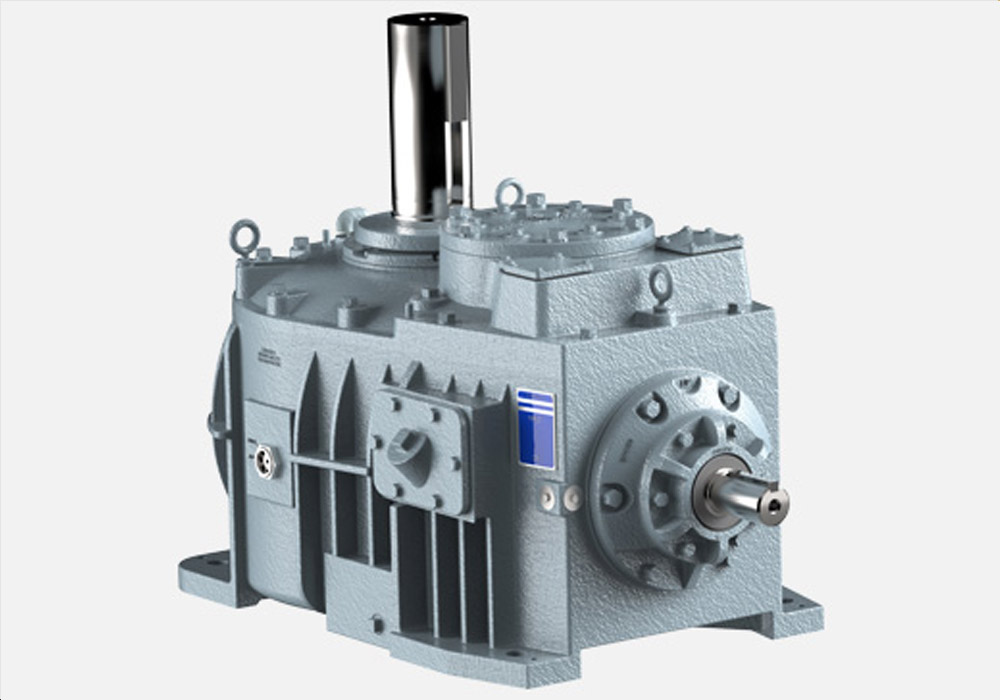

reductor de engranajes® – Serie M

Piezas de la torre de enfriamiento

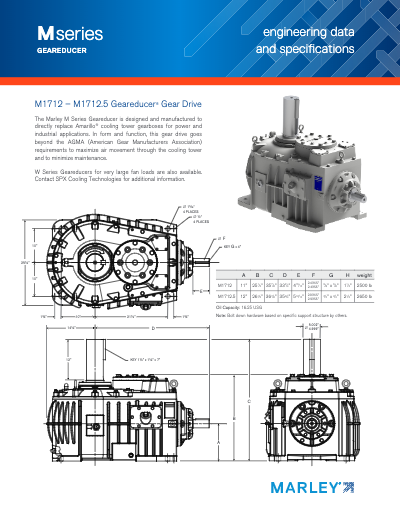

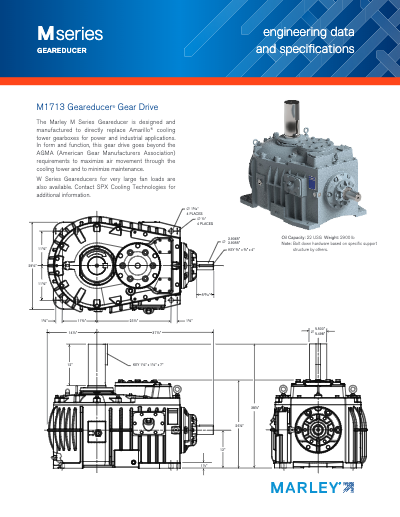

Detalles de producto:

Diseñado específicamente para tareas de torre de enfriamiento

Diseñado para cumplir o superar los requisitos de CTI Std. Normas 111 y AGMA.

Vida útil mínima de L10A de 100.000 horas en los ejes de entrada y salida

Sello de aceite tipo labio de larga duración en el eje de entrada

Eje de salida sellado con un anillo laberíntico que no requiere mantenimiento

Rodamientos de rodillos cónicos Timken

Reducción de engranajes de dos etapas (cónico en espiral/helicoidal) para una transmisión de potencia eficiente

Combinando la longevidad y el rendimiento comprobados de las robustas carcasas y rodamientos de Marley con modernas mejoras en los sellos y montaje de transductor de vibración incorporado, la completa Serie M elimina la necesidad de bombas, filtros o refrigeradores adicionales para funcionar correctamente. Las aletas de refrigeración externas y los grandes conductos internos de aceite contribuyen a mantener la Serie M funcionando fría y a prolongar la vida útil del aceite. También optimiza el rendimiento del ventilador de la torre de enfriamiento con niveles mínimos de ruido, pérdidas de transmisión y vibración. La Serie M es una alternativa avanzada de primer nivel a los reductores de velocidad como los producidos por Amarillo.

Los Geareducers de Marley resisten las temperaturas y la humedad extremas de los entornos de las torres de enfriamiento. Y, dado que garantizamos no solo el Geareducer, sino también el rendimiento térmico de la torre de enfriamiento que soporta, el diseño, la ingeniería y la fabricación se toman muy en serio. Esto da como resultado un funcionamiento más confiable y un ciclo de vida más largo: una solución superior para grandes aplicaciones industriales y de plantas de energía.