Marley série 10 et série 15

Tour de refroidissement à flux transversal érigée sur site

Détails du produit:

Disponibilité: Mondial

Plage de gal/min : 135-6720

Conforme à l'OSHA

Modifications de la charge de vent pour respecter le code du bâtiment de Floride

Options sismiques élevées pour les zones sismiques

Idéal pour les moulins à papier, en acier ou à sucre, ou là où la température de l'eau dépasse 140 °F (60 °C).

Garantie de 5 ans sur les équipements mécaniques pour la plupart des applications

Qu'est-ce qu'une tour de refroidissement ?

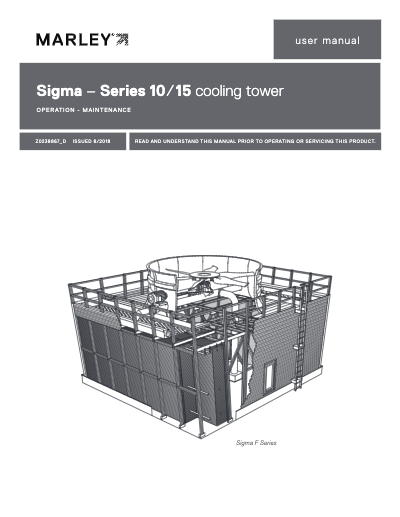

Les tours de refroidissement des séries 10 et 15 sont construit sur le terrain, remplissage par éclaboussures, flux croisés, tours de refroidissement en bois. Ils sont conçus pour desservir tous les systèmes d'eau de refroidissement normaux, y compris les systèmes « d'eau sale », ce qui mettrait en péril le fonctionnement à long terme d'une tour de remplissage de film.

Les séries 10 et 15 sont conçues pour entretien facile pendant le fonctionnement, ce qui est essentiel pour les applications d'eau sale. Depuis plus de 50 ans, ils établissent la norme en matière de fiabilité à long terme dans les pires conditions.

Coûts de maintenance réduits: Les ventilateurs robustes en alliage d'aluminium ou en époxy renforcé de fibres, les réducteurs à engrenages en fonte et les arbres de transmission en acier inoxydable ne nécessitent qu'un entretien périodique. Des matériaux nécessitant peu d’entretien sont utilisés dans toute la tour de refroidissement. Le remplissage par éclaboussures largement espacé aide à prévenir le colmatage. La zone de remplissage est facilement accessible pour le nettoyage.

Garantie de cinq ans sur la transmission – la plupart des applications: Quel autre fabricant garantira les équipements mécaniques de votre tour pendant cinq années complètes ? Vous économiserez de précieux dollars d’entretien de l’équipement.

Performances éprouvées: Marley assume sa responsabilité en matière de performances thermiques fiables. Nous l'avons conçu. Nous l'évaluons. Nous le garantissons !

Disponibilité des pièces auprès d'une source unique: Tous les composants de la tour, à l'exception des moteurs électriques, sont conçus, fabriqués et garantis par SPX Cooling Technologies. Vous savez toujours à qui faire appel pour les pièces dont vous avez besoin. Vous êtes également assuré que tous les composants de la tour de refroidissement fonctionneront ensemble, car ils ont été conçus pour fonctionner ensemble.

Capacité de refroidissement flexible: Vingt-quatre modèles de tour avec des capacités allant jusqu'à 6 720 GPM par cellule de ventilateur offrent la flexibilité nécessaire pour s'adapter à presque tous les travaux. Une plus grande capacité de tour de refroidissement est disponible avec plusieurs cellules de ventilateur.

Dérive extrêmement faible: XCEL® drift eliminators really get rid of the costly nuisance of drift spotting on objects around the tower. The corrosion resistance of PVC assures you that you may never have to replace eliminators for the life of the cooling tower. Herringbone wood drift eliminators are available for certain applications that may encounter high temperatures or a high potential for clogging.

Durée de vie plus longue: La structure et les barres de remplissage en sapin de Douglas traité sous pression, les grilles de support de remplissage en FRP, les éliminateurs de dérive en PVC et tous les autres composants de la tour de refroidissement sont conçus pour des années de service.

Cylindres de ventilateur: et leurs entrées facilitées associées, augmentent le fonctionnement du ventilateur.

Combinaisons de remplissage et de ventilation: se soutiennent mutuellement pour des performances thermiques maximales dans la configuration du système.

Buses et distribution d'eau: les systèmes assurent une couverture de remplissage uniforme sans contribution excessive aux pertes de pression d'air.

Le réducteur de vitesse: fournit des vitesses de ventilateur constamment optimales et fonctionne de manière fiable dans un mélange air/vapeur saturé de nature corrosive.

Moteurs de ventilateur: sont conçus selon les spécifications Marley pour les exigences supplémentaires liées aux tours de refroidissement. Les moteurs sont isolés avec une protection supplémentaire contre l'humidité.

Arbres de transmission: sont conçus pour absorber les charges de choc opérationnelles, augmentant ainsi la durée de vie de ces composants critiques.

Merci pour votre récent achat auprès de SPX Cooling Technologies, Inc. Nous apprécions votre confiance et sommes impatients de vous servir à l'avenir.

Avantages de l'enregistrement de votre produit SPX :

VOUS ÊTES GARANTI ! L'installation de votre produit est vérifiée et la garantie est activée.

VOUS ÊTES AVERTI ! Vous recevez une notification immédiate des informations importantes sur le produit et des alertes de service.

VOUS ÊTES INCLUS ! Vous recevez des invitations à des programmes et événements éducatifs exclusifs, notamment School of Cool® ateliers de maintenance de tours.

NOUS VOUS ENTENDONS! Vos opinions sur nos produits, services, support technique et programmation sont demandées dans des enquêtes vocales auprès des clients.

Les conditions de garantie limitée de SPX Cooling Technologies s'appliqueront. Pour plus de détails sur votre couverture de garantie, veuillez consulter le certificat de garantie inclus avec votre produit.

Remplissez le formulaire ci-dessous pour enregistrer votre produit. Veuillez vous assurer que les informations fournies sont exactes – tous les champs sont obligatoires pour enregistrer votre produit.