Refroidisseur de fluide Marley LW

Refroidisseur de fluide par évaporation

Détails du produit:

Refroidisseur de fluide hybride à remplissage/serpentin à contre-courant à tirage induit

Disponibilité: Mondial

Capacité thermique : 26 à 107 tonnes (114 à 470 kW) par cellule

Plage de débit : 20 à 1 200 gpm (5 à 273 m3/h) par cellule

Les ventilateurs à entraînement direct (standard) éliminent l'entretien de l'entraînement par courroie

Installation monobloc, faible hauteur

Avantages de la maintenance et de l’accès

Certifié CTI

Conforme à la norme ASHRAE 90.1

Conforme à l'OSHA

Le Refroidisseur de fluide Marley LW est un refroidisseur de fluide en circuit fermé à contre-courant et à tirage induit utilisant une technologie brevetée de transfert de chaleur. Les LW hauteur inférieure et construction compacte avec commandes installées en usine répondre à de nombreuses restrictions de hauteur du code municipal.

En déplaçant les étapes d'assemblage clés généralement effectuées sur site vers l'atelier de fabrication, le LW offre également des avantages d'installation et de maintenance qui répondent efficacement à la diminution des bassins de main-d’œuvre qualifiée et aux budgets limités.

Applications

Le Marley LW est bien adapté aux applications CVC, notamment les pompes à chaleur à eau pour les bâtiments commerciaux et les immeubles résidentiels à logements multiples, les systèmes à débit de réfrigérant variable (VRF) refroidis à l'eau et les systèmes montés sur châssis. Il convient également parfaitement aux applications industrielles telles que les compresseurs, les enveloppes de machines et le refroidissement des fluides de traitement. Le refroidisseur de fluide Marley LW est une option viable pour les spécifications exigeant des tâches de rejet de chaleur inférieures à 200 tonnes, des tours de refroidissement à circuit fermé à contre-courant, le remplacement d'un refroidisseur de fluide à tirage forcé extérieur, des exigences de hauteur ou de poids inférieures ou des restrictions de redondance.

Avantages de l'installation

Avec des hauteurs d'unité standard inférieures à 10,5 pieds, le refroidisseur de fluide Marley LW répond à de nombreuses limitations de hauteur des codes municipaux et offre des avantages pour les installations sur les toits où une faible visibilité est importante. Les autres avantages incluent une installation monobloc, une connexion électrique en un seul point, des commandes installées en usine, ainsi qu'un câblage et des tests en usine.

Avantages de l'entretien

Avec 6 à 10 grandes portes d'accès rectangulaires par cellule stratégiquement situées pour permettre une inspection et un entretien faciles des composants intérieurs, y compris les compartiments de pulvérisation, de serpentin et de remplissage, le LW facilite l'accès à un autre niveau. Les portes d'accès fournissent des joints étanches à l'air et à l'eau sans utiliser de joints ou de fixations.

Technologie brevetée de transfert de chaleur

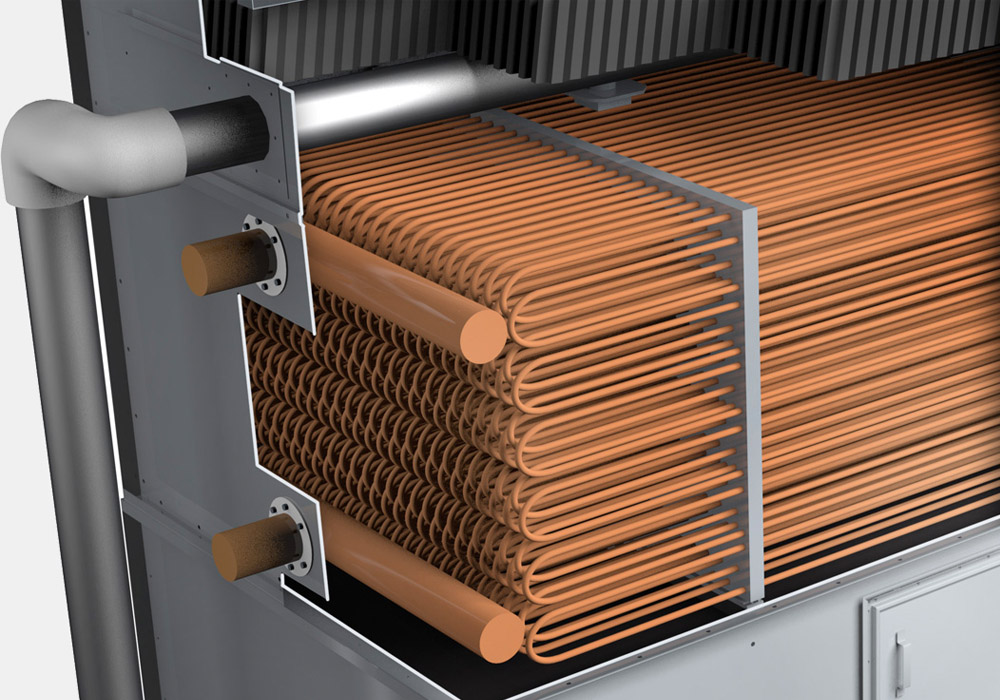

Le Marley LW utilise des serpentins de transfert de chaleur spécialement conçus en conjonction avec un film de remplissage en PVC pour améliorer considérablement le transfert de chaleur par évaporation. La conception unique du serpentin réduit considérablement sa résistance au flux d'air, réduisant ainsi les besoins en puissance du ventilateur et augmentant la capacité de rejet de chaleur dans une taille d'unité donnée en permettant à plus d'air de circuler à travers le média de remplissage à haute efficacité.

Ventilateurs à entraînement direct

Les ventilateurs à entraînement direct éliminent l'entretien de routine généralement requis pour les équipements entraînés par courroie, y compris la tension périodique de la courroie et le regraissage des roulements. Les ventilateurs sont câblés en usine au panneau de commande de l'unité, qui est testé en usine et expédié monté sur l'unité pour une mise en service facile sur site.

- Ventilateurs à entraînement direct ECM

Les entraînements de ventilateur standard intègrent des moteurs à commutation électronique (ECM) à haut rendement avec vitesse intégrée

contrôle. Les entraînements de ventilateur ECM assurent un fonctionnement efficace à des niveaux sonores exceptionnellement bas. - Ventilateurs à entraînement direct avec moteur à courant alternatif (modèles LWA)

Un système d'entraînement en option utilisant des moteurs de ventilateur NEMA à haut rendement est disponible, conçu pour être utilisé avec des entraînements à vitesse variable (VFD) externes. Les modèles équipés de moteurs AC (modèles LWA) offrent les mêmes performances que les modèles équipés de variateurs ECM, avec des niveaux sonores légèrement plus élevés en guise de compromis pour une disponibilité améliorée dans un monde de vulnérabilités en matière d'alimentation électronique.

Serpentin d'échange de chaleur en cuivre

Les serpentins de transfert de chaleur en cuivre offrent une résistance à la corrosion et une plus grande efficacité thermique, ce qui contribue à la taille compacte de l'équipement du refroidisseur de fluide LW, à son poids réduit et à sa longue durée de vie. Les bobines de cuivre sont 30 à 40 % plus légères que les bobines d'acier galvanisé comparables. Les serpentins en cuivre nécessitent moins de volume de fluide de traitement et sont bactériostatiques et recyclables. Plusieurs configurations de serpentins sont disponibles pour équilibrer la capacité de transfert de chaleur, la chute de pression du fluide et l'équipement.

Système de distribution d'eau résistant au colmatage

Les buses de pulvérisation à grand orifice de 1-7/8" aident à prévenir l'accumulation de débris et le colmatage.

Portes d'accès multiples

6 à 10 portes sans joint par cellule sont amovibles sans outils et permettent un accès facile aux composants intérieurs, notamment les compartiments de pulvérisation, de serpentin et de remplissage.

Construction robuste

Le refroidisseur de fluide LW comprend en standard un bassin de collecte boulonné en acier inoxydable. Toutes les pièces du bassin de collecte et d'entrée d'air exposées à l'eau en circulation, y compris les supports de serpentin, le matériel de fixation et les composants de bassin en option, sont en acier inoxydable de gros calibre de la série 300. Le reste de la structure de la tour et les supports mécaniques sont fabriqués en acier galvanisé lourd.

Persiennes d'entrée d'air en PVC

Les persiennes d'entrée d'air en PVC limitent les éclaboussures et offrent également un accès facile au bassin de collecte de tous les côtés.

Éliminateurs de dérive en PVC

Les éliminateurs de PVC à triple passage à haute efficacité limitent les pertes par dérive et sont facilement retirés pour inspection.

2. L'eau de recirculation est pompée du bassin de collecte vers le système de distribution sous pression et distribuée sur les serpentins.

3. L'eau de recirculation s'écoule à l'extérieur des tubes du serpentin, élimine la chaleur du fluide de procédé et s'écoule vers le fluide de remplissage situé sous les serpentins.

4. L'air induit à travers le refroidisseur de fluide évapore une petite partie de l'eau en recirculation, rejetant la chaleur dans l'atmosphère.