Raffreddatore di liquidi Marley LW

Raffreddatore di fluido evaporativo

Dettagli del prodotto:

Raffreddatore di fluido ibrido con riempimento in controcorrente a tiraggio indotto

Disponibilità: In tutto il mondo

Capacità termica: 26 – 107 tonnellate (114 – 470 kW) per cella

Intervallo di flusso: 20 – 1200 gpm (5 – 273 m3/ora) per cella

I ventilatori a trasmissione diretta (standard) eliminano la manutenzione della trasmissione a cinghia

Installazione in un unico pezzo, altezza ridotta

Vantaggi di manutenzione e accesso

Certificato CTI

Conforme ASHRAE 90.1

Conforme all'OSHA

IL Raffreddatore di liquidi Marley LW è un raffreddatore di fluido a circuito chiuso a controcorrente a tiraggio indotto che utilizza una tecnologia brevettata di trasferimento del calore. I LW altezza inferiore E costruzione compatta con controlli installati in fabbrica affrontare molte restrizioni sull'altezza del codice municipale.

Spostando le fasi chiave dell'assemblaggio, generalmente eseguite in loco, nel reparto di produzione, LW offre anche notevoli vantaggi vantaggi di installazione e manutenzione che affrontano efficacemente la riduzione del bacino di manodopera qualificata e i budget limitati.

Applicazioni

Marley LW è particolarmente adatto per applicazioni HVAC, comprese pompe di calore ad acqua per edifici commerciali e grattacieli residenziali con più unità, flusso di refrigerante variabile raffreddato ad acqua (VRF) e sistemi montati su skid. Si adatta perfettamente anche ad applicazioni industriali quali compressori, camicie di macchine e raffreddamento di fluidi di processo. Il raffreddatore di fluidi Marley LW è un'opzione valida per le specifiche che richiedono attività di smaltimento del calore inferiori a 200 tonnellate, torri di raffreddamento a circuito chiuso in controcorrente, sostituzione del raffreddatore di fluido a tiraggio forzato esterno, requisiti di altezza o peso inferiori o restrizioni di ridondanza.

Vantaggi dell'installazione

Con un'altezza standard dell'unità inferiore a 10,5 piedi, il raffreddatore di fluidi Marley LW soddisfa molti limiti di altezza dei codici municipali e offre vantaggi per le installazioni su tetto dove la scarsa visibilità è importante. Altri vantaggi includono l'installazione in un unico pezzo, la connessione di alimentazione a punto singolo, i controlli installati in fabbrica, il cablaggio e i test in fabbrica.

Vantaggi della manutenzione

Con 6-10 grandi porte di accesso rettangolari per cella posizionate strategicamente per consentire una facile ispezione e manutenzione dei componenti interni, inclusi scomparti spray, bobine e riempimento, LW porta la facilità di accesso ad un altro livello. Le porte di accesso forniscono guarnizioni ermetiche e stagne senza l'uso di guarnizioni o elementi di fissaggio.

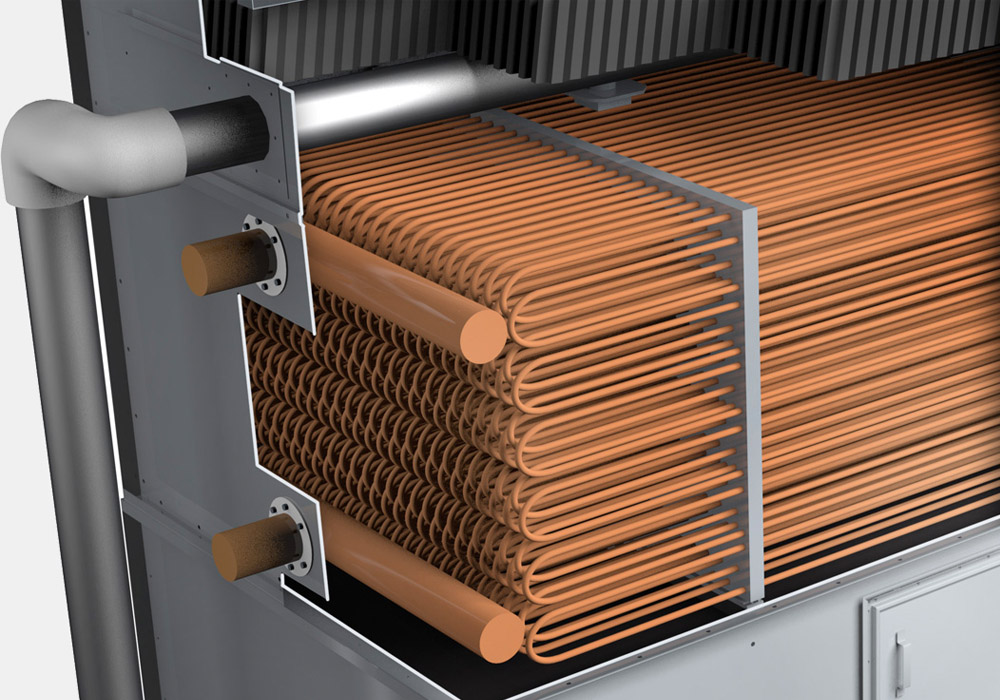

Tecnologia brevettata di trasferimento del calore

Il Marley LW utilizza bobine di trasferimento di calore appositamente progettate insieme a mezzi di riempimento in pellicola di PVC per migliorare significativamente il trasferimento di calore per evaporazione. Il design esclusivo della batteria riduce drasticamente la resistenza al flusso d'aria, diminuendo i requisiti di potenza della ventola e aumentando la capacità di smaltimento del calore in una determinata dimensione dell'unità consentendo a più aria di muoversi attraverso il mezzo di riempimento ad alta efficienza.

Ventilatori a trasmissione diretta

I ventilatori a trasmissione diretta eliminano la manutenzione ordinaria normalmente richiesta per le apparecchiature con trasmissione a cinghia, compresi il tensionamento periodico della cinghia e il reingrassaggio dei cuscinetti. I ventilatori sono cablati in fabbrica al pannello di controllo dell'unità, che viene testato in fabbrica e spedito montato sull'unità per una facile messa in servizio in loco.

- Ventole a trasmissione diretta ECM

Gli azionamenti dei ventilatori standard incorporano motori a commutazione elettronica (ECM) ad alta efficienza con velocità integrata

controllo. Gli azionamenti delle ventole ECM garantiscono un funzionamento efficiente a livelli sonori eccezionalmente bassi. - Ventole a trasmissione diretta con motore CA (modelli LWA)

È disponibile un sistema di azionamento opzionale che utilizza motori dei ventilatori NEMA ad alta efficienza, progettato per l'uso con azionamenti a velocità variabile (VFD) esterni. I modelli con motori CA (modelli LWA) offrono le stesse prestazioni dell'unità dei modelli con azionamenti ECM, con livelli sonori leggermente più elevati come compromesso per una migliore disponibilità in un mondo di vulnerabilità dell'alimentazione elettronica.

Batteria di scambio termico in rame

Le serpentine di trasferimento del calore in rame offrono resistenza alla corrosione e maggiore efficienza termica, che contribuiscono alle dimensioni compatte dell'apparecchiatura, al peso inferiore e alla lunga durata del raffreddatore di fluido LW. Le bobine in rame sono più leggere del 30-40% rispetto alle bobine in acciaio zincato comparabili. Le batterie in rame richiedono meno volume di fluido di processo e sono batteriostatiche e riciclabili. Sono disponibili molteplici configurazioni della batteria per bilanciare la capacità di trasferimento del calore, la caduta di pressione del fluido e le apparecchiature.

Sistema di distribuzione dell'acqua resistente agli intasamenti

Gli ugelli di spruzzatura con orifizio di grandi dimensioni da 1-7/8” aiutano a prevenire l'accumulo di detriti e l'intasamento.

Porte di accesso multiple

6-10 porte senza guarnizioni per cella sono rimovibili senza attrezzi e consentono un facile accesso ai componenti interni, compresi i compartimenti di spray, bobina e riempimento.

Costruzione robusta

Il raffreddatore di fluidi LW include di serie una vasca di raccolta imbullonata in acciaio inossidabile. Tutte le parti del bacino di raccolta e di ingresso dell'aria esposte all'acqua circolante, compresi i supporti delle serpentine, la bulloneria di fissaggio e i componenti opzionali del bacino, sono in acciaio inossidabile di grosso spessore della serie 300. L'equilibrio della struttura della torre e i supporti meccanici sono realizzati in acciaio zincato pesante.

Alette di ingresso dell'aria in PVC

Le alette di ingresso dell'aria in PVC limitano gli schizzi e offrono inoltre un facile accesso alla vasca di raccolta da tutti i lati.

Eliminatori di gocce in PVC

Gli eliminatori in PVC a triplo passaggio ad alta efficienza limitano le perdite dovute alla deriva e sono facilmente rimovibili per l'ispezione.

2. L'acqua di ricircolo viene pompata dal bacino di raccolta al sistema di distribuzione pressurizzato e viene distribuita sulle batterie.

3. L'acqua di ricircolo scorre all'esterno dei tubi delle batterie, rimuove il calore dal fluido di processo e scorre sul mezzo di riempimento sotto le batterie.

4. L'aria indotta attraverso il raffreddatore del fluido fa evaporare una piccola parte dell'acqua ricircolante, cedendo calore all'atmosfera.