Marley CoolBoost™ Opti AD

Panel de control

Descripción general

CoolBoost Opti AD helps optimize system performance through the conservation of energy or water, and offers other benefits including an upgraded user interface and faster integration.

Energy and Cost Efficient

With the speed controller and impeller built into a single module, easily operate EC fans offering increased efficiency, reduced energy consumption and minimizes maintenance costs.

Flexible Operating Modes to Optimize System Performance

The full range of operating environments are satisfied by the software. Optimize between energy and water savings:

– ECM (Energy Conservation Mode)

– WCM (Water Conservation Mode)

Modernized Interface and Control Logic Provides Intuitive Operation

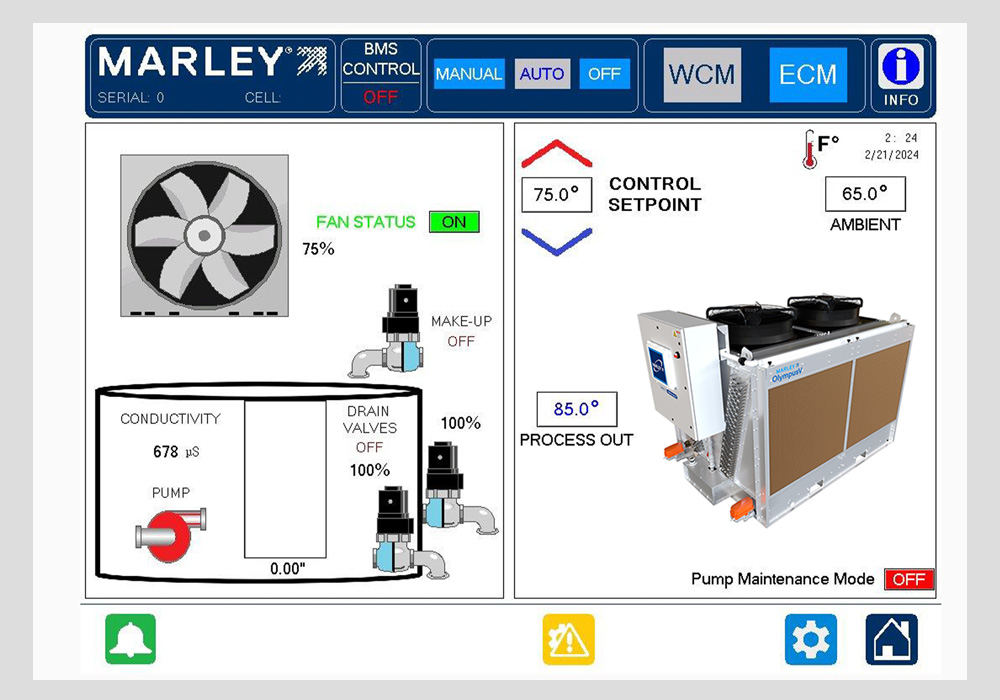

One enclosure for all Adiabatic control needs: PLC, HMI, Pump, Fan, Communication and Water Level. Comprehensive dashboard provides all status conditions at a glance. Operating commands of the Integral PLC allows control source options: BMS/BAS, Manual, Auto or Off.

Saves System Integration Time:

The Control Panels of Adiabatic EC units are prewired at the factory and provides Single Point Power Connection. The “plug and play” configuration saves customer panel design time and electrician hours. RS845 compatibility simplifies integration into BMS systems for monitoring, controlling remotely, and saving historical data.

- Integrated PLC provides run commands and operating logic for the fan motor’s, adiabatic spray and water management.

- HMI enables the unit displays status and allows different modes of operation.

- Ethernet communication is integrated to monitor status, compile historical data collection and enable remote operation.

- NEMA 3R painted cabinet includes an external disconnect handle with padlocking provision to meet lockout/tagout safety requirements.

- El disyuntor principal tiene protección contra sobrecarga térmica y magnética.

Opciones

- Fluid-in temperature RTD for fluid cooler configuration.

- NEMA 4X stainless steel or fiberglass enclosure.

- Process monitoring transducers provide real time system feedback:

- Process Fluid Out Temperature

- Ambient Temperature.

- Los disyuntores de protección del motor protegen contra corrientes de sobrecarga y cortocircuito.

- Wiring diagram is laminated and mounted inside the enclosure panel for easy troubleshooting.

- Integrated Liquid Level Control Ultrasonic.

- 65K SCCR, Short Circuit Current Rating.

- Construido según los requisitos de seguridad UL508 y cUL508.