Refroidissement par évaporation : utiliser l'eau à bon escient

Soutenez les efforts de conservation de l’eau avec votre technologie de tour de refroidissement.

Ressources pour la conservation de l'eau dans les tours de refroidissement

Produits conçus pour réduire la consommation d’eau :

QUESTIONS FRÉQUEMMENT POSÉES

Les tours de refroidissement par évaporation gaspillent-elles beaucoup d’eau ?

Plus la charge thermique et/ou la température ambiante sont faibles, moins l'évaporation est importante. Plus les cycles de concentration (COC) du système sont élevés, plus la purge est faible. Pour en savoir plus sur la limitation de l'évaporation et/ou de la purge, consultez notre livre blanc, «Comment conserver l'eau dans les tours de refroidissement par évaporation.”

La consommation d’eau varie considérablement en fonction du style de tour, de l’application et des conditions de l’eau entrant dans le système.

Les tours refroidies par eau consomment-elles plus d’eau que les tours refroidies par air ?

Pour en savoir plus, téléchargez l'article ASHRAE, «Un examen de l’efficacité et de la valeur environnementale du refroidissement par évaporation.« Cet article montre la quantité d’eau utilisée hors site lorsque vous utilisez une technologie moins économe en énergie pour votre système mécanique.

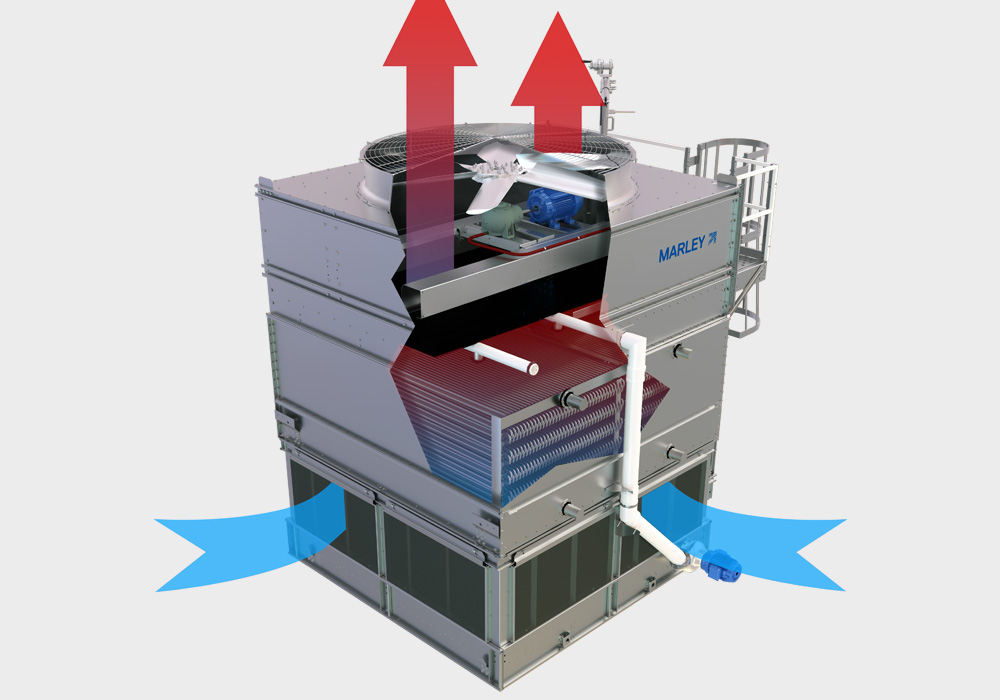

Une autre option d'économie d'eau qui devient de plus en plus populaire pour une variété d'applications est un système de refroidissement adiabatique. Marly® Olympus V® Série adiabatique équilibre les avantages d'économie d'eau d'un système de rejet de chaleur refroidi par air avec l'efficacité énergétique d'une solution refroidie par eau pour fournir un refroidissement flexible aux opérateurs et aux ingénieurs.

Puis-je conserver l’eau dans mon système mécanique existant ?

Comment puis-je savoir quelle quantité d’eau j’utilise ou utiliserai ?

Si vous avez besoin d'aide pour déterminer les conditions de votre projet ou de votre bâtiment, un représentant Marley à proximité peut vous aider à recueillir les bonnes informations et à trouver la meilleure solution pour vos efforts de conservation de l'eau.

Est-ce que modifier mon débit de circulation peut réduire ma consommation d’eau ?

En bref, non. Le taux d'évaporation suit de près la charge thermique, que le débit d'eau soit élevé ou faible. Le rapport liquide/gaz, également appelé L/G (et défini comme le débit massique d'eau divisé par le débit massique d'air) a un faible impact sur l'évaporation. Si la quantité d'eau est inférieure à la quantité d'air (un faible rapport L/G), une plus grande évaporation peut se produire et vice versa. Cependant, la configuration du produit et les conditions thermiques cibles dictent le débit d'air requis. Si économiser l’eau est important, consultez un représentant SPX/Marley pour comprendre les options disponibles.

Le taux d’évaporation change-t-il en fonction de l’emplacement ?

Oui, le taux d’évaporation est directement affecté par les conditions ambiantes. L’atmosphère des climats chauds et secs présente une humidité relative très faible. Cet air peut naturellement accepter plus de vapeur d’eau, ce qui augmente le taux d’évaporation. À l’inverse, un produit de même configuration installé dans un environnement plus humide présentera un taux d’évaporation plus faible. L’autre facteur principal est l’altitude. Lorsque la pression barométrique diminue à des altitudes plus élevées, le taux d’évaporation augmente. Pour plus d'informations concernant votre application spécifique, veuillez contacter un représentant SPX/Marley.

Quelle est la consommation d’eau typique d’un produit à évaporation ?

Il n’existe pas de règles universelles applicables à toutes les applications et zones climatiques. Les facteurs déterminants sont la charge thermique, le climat et le profil de charge tout au long de l’année. Il n’est pas exact de supposer que l’évaporation journalière de conception est constante toute l’année. Le taux d’évaporation diminue pendant les périodes les plus fraîches de l’année et lorsque la charge diminue, ce qui est courant dans les systèmes CVC. Les produits à évaporation sont économes en énergie et respectueux de l’environnement. Sans l’utilisation de l’évaporation, des modes de refroidissement moins économes en énergie seraient utilisés, ce qui entraînerait une plus grande consommation d’eau dans la centrale électrique. Si économiser l’eau est important, consultez un représentant SPX/Marley pour comprendre les options disponibles.