Evaporative Cooling: Using Water with Purpose

Support Water Conservation Efforts with Your Cooling Tower Technology.

Resources for water conservation in cooling towers

Products designed to lower water usage:

FREQUENTLY ASKED QUESTIONS

Do evaporative cooling towers waste a lot of water?

The lower the heat load and/or ambient temperature, the less evaporation. The higher the system’s cycles of concentration (COC), the lower the blowdown. For more about limiting evaporation and/or blowdown, see our white paper, “How to Conserve Water in Evaporative Cooling Towers.”

Water usage will vary greatly depending on the style of tower, the application and the conditions of the water entering the system.

Do water-cooled towers use more water than air-cooled towers?

To learn more about this, download the ASHRAE article, “A Review of Evaporative Cooling’s Efficiency and Environmental Value.” This article shows how much water is used offsite when employing less-energy-efficient technology for your mechanical system.

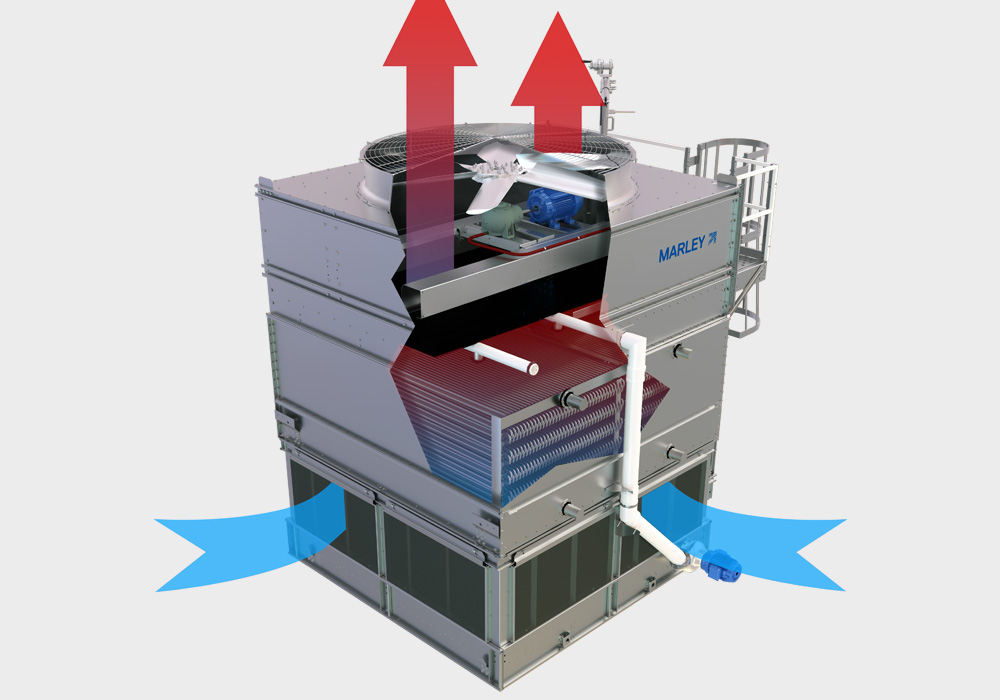

Another water-saving option that’s becoming more popular for a variety of applications is an adiabatic cooling system. The Marley® OlympusV™ Adiabatic Series balances the water-saving benefits of an air-cooled heat rejection system with the energy efficiency of a water-cooled solution to provide flexible cooling for operators and engineers.

Can I conserve water in my existing mechanical system?

How do I know how much water I am using or will use?

If you need help determining the conditions of your project or building, a nearby Marley representative can help you gather the right information and find the best solution for your water conservation efforts.

Can changing my circulating flow rate reduce my water usage?

In short, no. Evaporation rate closely follows heat load, regardless of whether water flow rate is high or low. The liquid-to-gas ratio, also known as L/G (and defined as mass flow of water divided by mass flow of air) has a small impact on evaporation. If the amount of water is less than the amount of air (a low L/G ratio), more evaporation can occur and vice versa. However, the product configuration and target thermal conditions dictate airflow required. If saving water is important, consult an SPX/Marley representative to understand the options available.

Does evaporation rate change based on location?

Yes, evaporation rate is directly impacted by the ambient conditions. The atmosphere in warm, dry climates is very low relative humidity. This air naturally can accept more water vapor, which drives up evaporation rate. Conversely, a product with the same configuration installed in a more humid environment will exhibit a lower evaporation rate. The other primary factor is elevation. As barometric pressure decreases at higher altitudes, evaporation rate increases. For more information regarding your specific application please contact an SPX/Marley representative.

What is the typical water usage of an evaporative product?

There are no universal rules that apply to every application and climate zone. The drivers are heat load, climate, and load profile throughout the year. It is not accurate to assume design day evaporation is constant year round. Evaporation rate decreases during cooler times of the year and when load decreases, which is common among HVAC systems. Evaporative products are energy efficient and environmentally friendly. Without the use of evaporation, less energy efficient modes of cooling would be used, which in turn drives more water usage at the power plant. If saving water is important, consult an SPX/Marley representative to understand the options available.