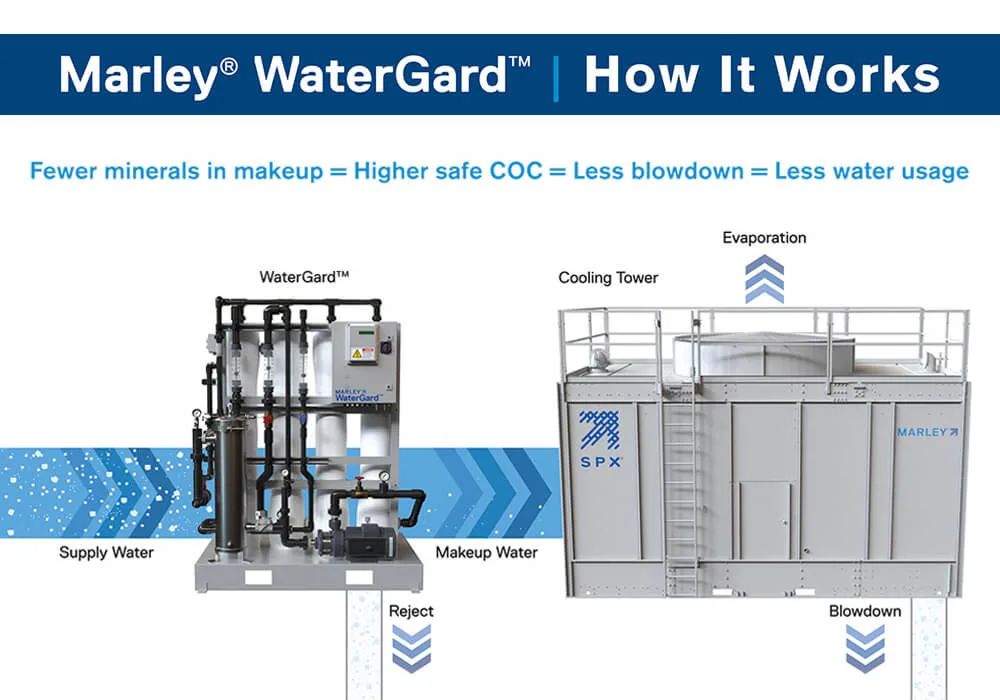

Marley WaterGard™

Water-Saving Membrane Filtration System for Evaporative Cooling Equipment

Product Details:

Availability: North America

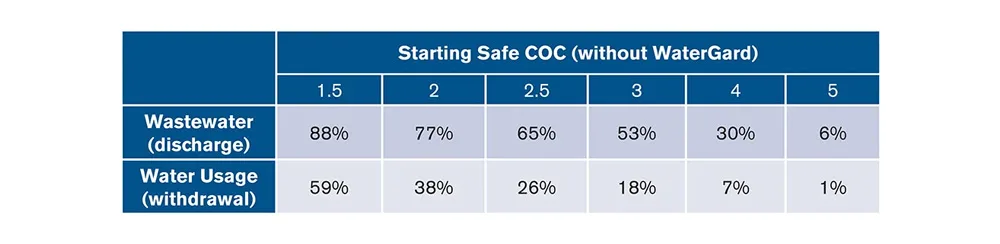

Reduces water usage (withdrawal)

up to 59%*

Reduces wastewater (discharge)

up to 88%*

Reduces discharge losses of water treatment chemicals

LEED points available

Augments existing water treatment

The WaterGard cooling tower filtration system physically blocks and rejects minerals commonly found in municipal water streams (chlorides, calcium carbonate, silica, etc.), reducing makeup water mineral content and enabling higher operating COC, resulting in reduced volume requirements for both blowdown and supply water.

The Marley WaterGard filtration system is the most viable solution for operators/specifiers with plans to conserve water, especially when one or more of the following conditions is true:

1. Local operating conditions are 3 cycles of concentration (COC) or less

2. Eligible for water usage incentive or rebate programs

3. Interested in earning LEED v4 credits for cooling tower water management

Potential Savings

Simple to Service

Typical expected consumables replacement:

- 24 month membrane change

- 12 month carbon refresh (if equipped)

- 3 months sediment filter change

Additional System Requirements

Required to achieve expected benefits and service life:

- Chlorine removal pre-treatment

- Electronic water level makeup

- Conductivity controlled blowdown

| Watergard Model | Peak Makeup Flow (GPM) | Membranes (Quantity x Size) | Approximate Dimensions W x D x H (in.) | Pump (HP) |

| WG002 | 2.2 | 2 x 4″ |

26” x 10” x 55” |

1 |

| WG004 | 4.4 | 4 x 4″ |

26” x 10” x 55” |

1 |

| WG007 | 7.3 | 6 x 4″ |

60” x 21” x 60” |

3.4 |

| WG009 | 9.0 | 8 x 4″ |

60” x 21” x 60” |

3.4 |

| WG012 | 12.2 | 2 x 8″ |

59” x 38” x 72” |

5.4 |

| WG018 | 18.3 | 3 x 8″ |

59” x 38” x 72” |

5.4 |

| WG024 | 24.4 | 4 x 8″ |

59” x 38” x 72” |

5.4 |

| WG037 | 36.5 | 6 x 8″ |

110” x 36” x 77” |

5.4 |

| WG049 | 48.8 | 8 x 8″ |

110” x 36” x 77” |

8.5 |

| WG055 | 54.8 | 9 x 8″ |

147” x 36” x 77” |

8.5 |

| WG061 | 60.8 | 10 x 8″ |

111” x 36” x 82” |

10 |

| WG073 | 73.0 | 12 x 8″ |

147” x 36” x 77” |

10 |

| WG091 | 91.3 | 15 x 8″ |

147” x 36” x 77” |

10 |

- Makeup water rates 2 – 91 gpm per unit

- Includes internal bypass function

- Not a replacement for water treatment

*Dimensions exclude carbon tank system (standard option) for chlorine removal pre-treatment

*Designed for indoor installation

*Typical municipal source water pressures 45-80 psig

*Integral pump included to offset membrane filter pressure drop

Patent-pending Marley® WaterGard™ pre-conditions cooling tower makeup water to enable equipment operation at increased Cycles of Concentration (COC), reducing wastewater and overall water usage.