皮带传动风扇系统

冷却塔部件

在动力传输选项中,皮带传动的 简单的设计 和 可制造性 使其成为一种经济高效的替代方案。SPX 冷却技术公司为多种冷却塔型号提供皮带传动装置。

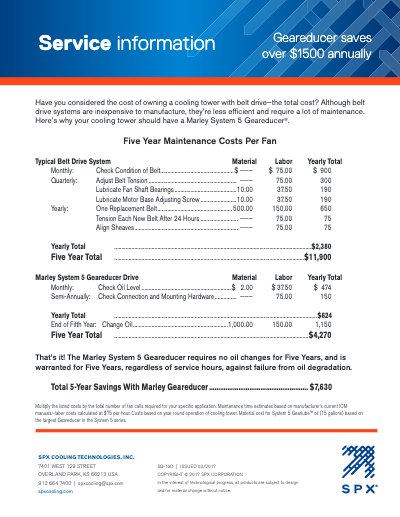

新型皮带传动效率约为 95%。除了初始成本低之外,皮带传动的外露部件需要频繁维护,因此预计运行成本会更高。

在皮带驱动的冷却塔中,电机和电机皮带轮为皮带提供动力,皮带通过皮带轮连接到风扇轴上。轴承和衬套将它们固定在一起。即使轴与轴之间的距离相当远,该技术也能在轴之间实现平稳有效的动力传输。需要定期润滑和张紧皮带,以确保正确的动力传输和冷却塔运行。随着时间的推移,由于皮带的拉伸和磨损,效率百分比可能会下降到 90% 以下甚至更低,需要更频繁地更换——通常每年一次。维护专业人员应每月进行一次检查,以检查皮带张力和对齐是否正确、润滑是否充分以及磨损迹象。

皮带传动常用于功率需求较低的冷却塔中。与齿轮传动一样,皮带传动不需要变频驱动器 (VFD)。Marley 减速器® 齿轮传动是一种更高效的替代方案,可节省能源、安装和维护成本。.