产品详情:

可用性: 欧洲和中东

流速: 774-4011 加仑/分钟(176-911 立方米/小时)

热容量: 258-1337吨(1134-5878千瓦)

CTI认证的热性能和噪声性能

经过 Eurovent 认证

根据欧洲钢结构规范 3(DIN EN 1993)设计。

工厂组装,无需现场焊接

也可提供预装模块或拆卸式

组装完毕后吊装完成的塔架

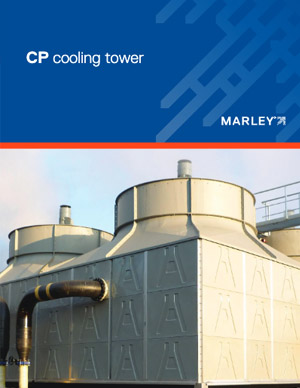

Marley CP 冷却塔是一种诱导通风、逆流冷却塔,专门设计用于 空间和声音敏感的应用. 它采用不锈钢内部结构和玻璃纤维增强聚酯 (FRP) 外壳,可抵抗腐蚀和化学侵蚀。

一系列传热填充介质可适应 从清洁水到非常脏的水的应用. Marley CP 冷却塔可完全在工厂组装,也可部分组装,或完全拆卸后运输到现场组装。

获得 CTI 和 Eurovent 认证

Marley CP冷却塔的热性能已通过冷却技术研究院 (CTI) 和 Eurovent 的测试和认证。此外,所有已公布的Marley CP冷却塔噪音数据均已通过CTI认证,因此您可以放心,您的冷却塔将符合规定的噪音水平。.

运作方式

热水通过 PVC(聚氯乙烯)或聚丙烯管道流入冷却塔,再进入配水系统。喷嘴将细小的热水液滴从传热填料上方均匀喷洒。冷却空气由引风轴流风扇提供。空气通过蒸发和对流吸收水中的热量。

传热填充介质

净水应用采用 PVC 或聚丙烯薄膜填料包。含有较高悬浮固体的污水需要防堵塞或防溅填料。

机械设备

风扇直接安装在减速电机轴上。风扇叶片间距可根据工艺条件进行调整。低噪音冷却塔电机经过精心设计,可承受高温和高湿度条件,适合使用变频驱动器 (VFD) 连续运行。电机和风扇安装在热镀锌 (HDG) 钢(或可选不锈钢)支撑结构上。

多单元配置

多单元 CP 冷却塔可以并列安装或背靠背安装。

电盆加热器: 浸入式加热器有助于防止寒冷天气下结冰。

电动油位开关: 监控齿轮马达油供应。

外部润滑管线: 方便更换油。

维护平台: 稳定的 HDG 钢工作表面可确保机械设备的安全使用。

震动开关: 自动关闭电机,有助于防止因高振动水平而导致的机械故障。

超静音风扇: 最大限度提高效率并降低噪音水平。

感谢您最近从 SPX Cooling Technologies, Inc. 购买产品。我们十分重视您的业务,并期待将来能为您服务。

注册 SPX 产品的好处:

你有权这么做! 您的产品安装已验证且保修已激活。

您已收到通知! 您会立即收到重要产品信息和服务警报的通知。

你也包括在内! 您将收到独家教育节目和活动的邀请,包括 School of Cool® 塔维护车间。

我们听到了您的声音! 我们在客户心声调查中征集了您对我们的产品、服务、技术支持和编程的意见。

将适用 SPX Cooling Technologies 的有限保修条款。有关保修范围的完整详情,请参阅产品随附的保修证书。

填写以下表格以注册您的产品。请确保提供的信息准确无误 – 为了注册您的产品,所有字段都是必填项。