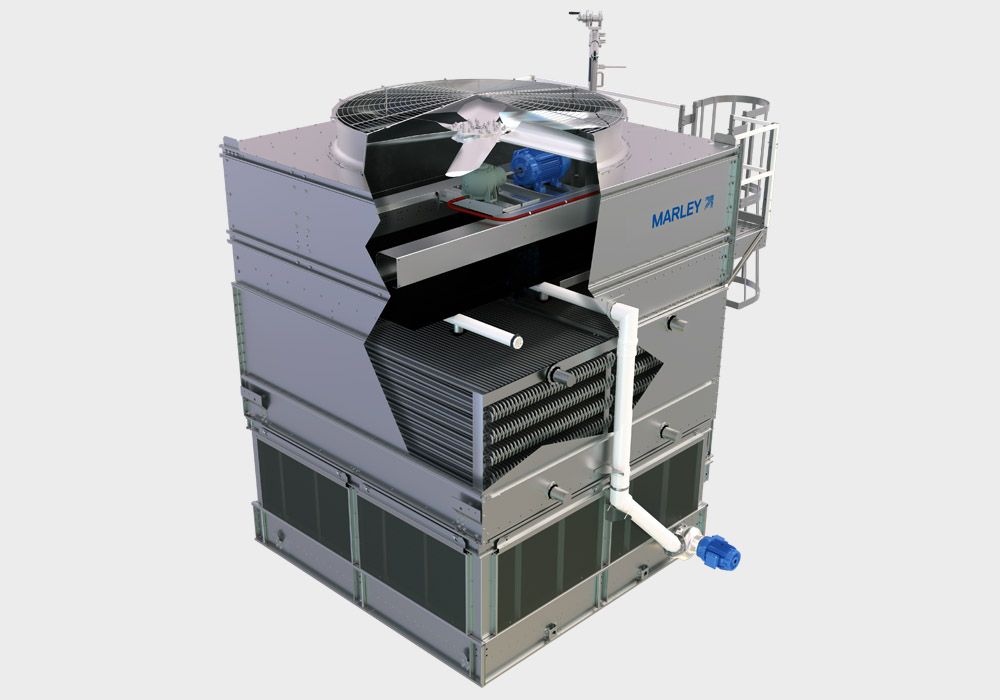

Marley DT 流体冷却器

蒸发式流体冷却器

产品详情:

诱导通风逆流闭式循环流体冷却器

可用性: 全世界

热容量: 每电池 58 – 321 吨 (255 – 1411 千瓦)

流量范围: 每室 80 – 1800 gpm(18 – 409 m3/hr)

全新 Aero-X 线圈技术

更高的干式切换点*

降低流体压降

获得 CTI 认证

符合 ASHRAE 90.1 标准

符合 OSHA 标准

目前单位面积标称制冷量最高

裸管盘管式液体冷却器

马利式冷却塔是一种采用引风式、仅使用盘管的闭式循环冷却塔。® 采用 Aero-X™ 盘管技术的 DT 流体冷却器提供了干式运行的灵活性,这是填充/盘管混合冷却器无法实现的。

Aero-X 线圈技术最大程度提高单位面积热容量*

最低的空气侧压降(在相同风扇 HP 下,气流量可增加高达 10%)和最高的单位面积标称散热能力(通过 DT 闭式冷却器的 Aero-X 盘管技术实现的优势)提供了减小设备尺寸和/或降低能耗的机会,同时保持了仅使用盘管的闭式冷却器所具有的干式操作灵活性。

更高的干式开关点 – 高达 10F+ 高*

无论季节性干运行的动机是减少现场用水量、最大限度地降低水处理成本还是简化冰冻条件下的操作,更高的干切换点温度都能在一年中的大部分时间里实现这些目标。DT 流体冷却器具有高达 10°F 以上的更高干切换点,可在干模式下实现每年最多 15-20% 的增量小时数。根据气候条件,在许多地区,每冷却吨每年可节省 3,000 加仑/吨和 $40/吨的水。可选的翅片盘管进一步增强了在较高环境温度下的干运行能力。

更低的流体压降 – 高达 30%

与上一代产品相比,泵送能量需求的降低对系统运行成本和能耗产生了积极影响。

翅片线圈选项 – 现在采用 Aero-X 线圈技术!

可选的 Aero-X 翅片盘管进一步增强了在较高环境温度下的干运行能力并提高了蒸发性能。与类似的裸管盘管型号相比,干球切换点最高可提高 20°F,蒸发性能最高可提高 30%。

*标称容量与其他仅采用裸管盘管的液体冷却器相比

正品 Marley 机械系统提供低维护成本和可靠的性能,并提供 5 年保修。皮带传动可选。

广泛的产品选择

从各种尺寸和布局的 DT 型号中进行选择,以满足您的特定冷却要求。

坚固的结构

坚固的镀锌钢外壳可容纳高品质的机械和传热系统。不锈钢组件选项(包括集水盆和裸管传热盘管)允许定制,以应对最苛刻的环境条件并延长使用寿命。

三通进风百叶

可拆卸的百叶窗包含三个方向的变化,以控制溅出物和阳光照射,以限制藻类的生长。

防堵塞喷雾系统

大孔喷嘴有助于防止碎片堆积和堵塞。

高效轴流风机

可调螺距风扇叶片可最大限度地利用额定马力并实现最佳冷却塔性能。

高效风扇电机

TEFC 1.15 使用系数电机按照 Marley 规格设计,并针对潮湿冷却塔条件进行了特殊绝缘。

PVC 除水器

高效的三重 PVC 消除器可限制漂移损失,并且易于拆卸进行检查。

大型检修门

通过门可以方便地进入机械系统、漂浮物消除器、配水系统和传热盘管。

降低噪音

经 CTI 认证的 DT 流体冷却器标配 Marley 低噪音风扇。有多种风扇和衰减选项可供选择,以满足更严格的降噪要求。

马利可靠性

重型结构、镀锌和不锈钢材料选择、高性能设计以及我们的五年机械保修确保在广泛的闭路冷却应用中保持一致的冷却。

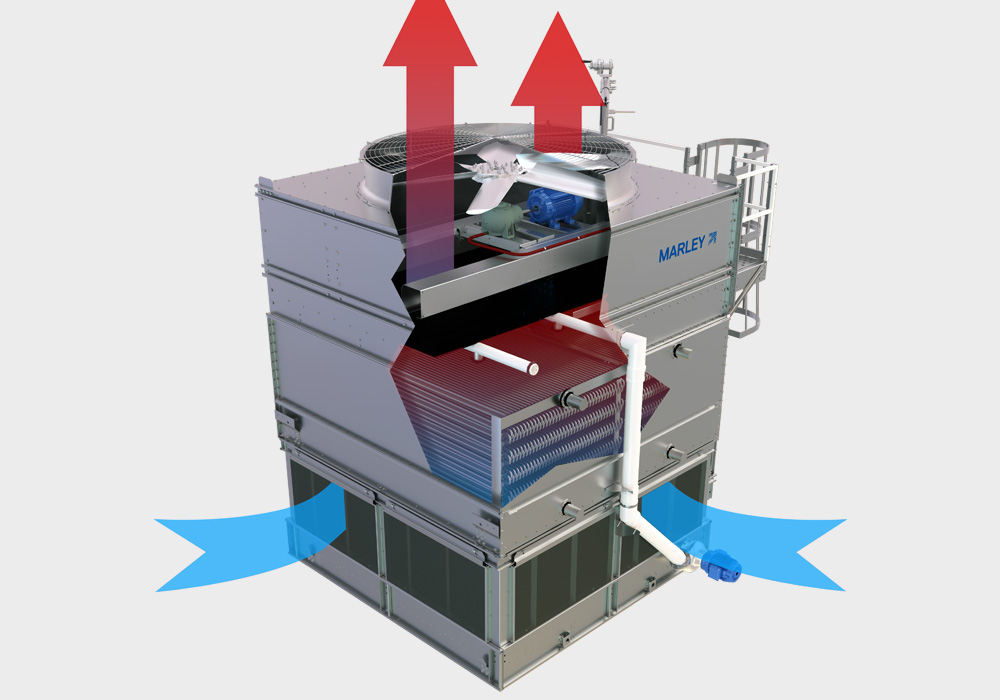

2. 循环水从集水盆泵送到加压分配系统,并均匀分布在盘管上。

3. 当工艺流体流过传热盘管外部时,热量从工艺流体传递到循环水。

4. 通过液体冷却器吸入的空气会蒸发一小部分循环水,将热量排放到大气中。