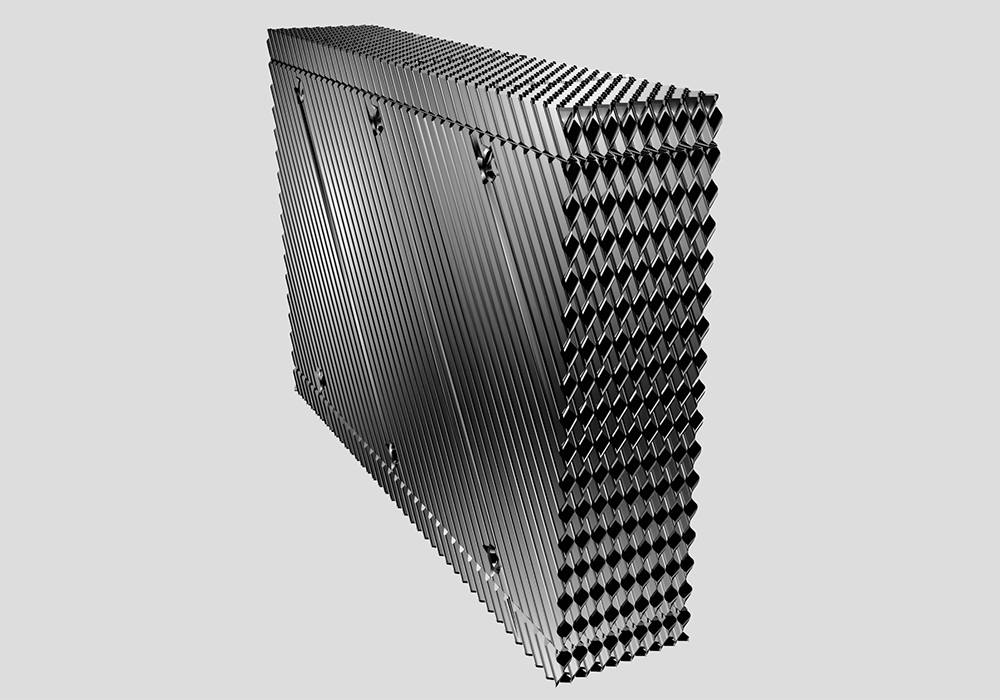

MC75 逆流薄膜填料

冷却塔部件

品牌: 马利 | 产品类型: 冷却塔部件

MC75 是一种专为逆流塔设计的薄膜填充系统,可为您提供多种独特的优势。

交叉波纹提供表面积和湍流,以产生高效的热传递。波纹本身就建立了均匀的填充板间距,间距为 0.75 英寸。

MC75 填充物由厚度为 0.015 的、防紫外线、耐化学腐蚀的聚氯乙烯 (PVC) 热成型而成。根据 ASTM E-84,火焰蔓延等级小于 25,并且被认为是自熄性的。

该材料在成型前按照严格的规格进行挤压和制造。使用 Marley MC75 薄膜填料代替逆流塔中现有的溅射式填料通常意味着填料高度降低,从而降低了泵送扬程。MC75 还将提供更大的冷却塔容量,这意味着您当前的性能水平将需要更少的风扇能量。

填料包深度(空气流动)是可变的,以在单个填料层内提供适当的传热面积。如果需要额外的空气流动,则必须使用另一层填料,但仅限于一层。限制填料包之间的接口数量可以最大限度地减少通常导致填料堵塞的限制。MC75 逆流填料可以悬挂在结构构件上,也可以在几乎所有逆流冷却塔中进行底部支撑,无论冷却塔的年龄或制造商如何。

高性能

悬挂或底部支撑设计

可变的空气行程尺寸

交叉波纹设计

悬挂或底部支撑设计

可变的空气行程尺寸

交叉波纹设计

正品 Marley OEM 零件经过精心设计,可为您提供可靠的产品。虽然其他供应商可能会以初始成本提供零件,但您可能会面临性能降低的风险,并且会失去 FM 和 CTI 评级。Marley OEM 零件提供您可以信赖的耐用性,因为我们专门为冷却塔设计和制造它们。

由于工厂的运行依赖于冷却塔的性能,因此选择质量最高的零件(Marley OEM 零件)非常重要。