冷却塔改造

概述

无论您的塔架是否接近其生命周期的末期,有更大的运营需求或经历了结构故障,SPX 都准备好了一系列解决方案,可以让您的运营快速恢复在线。

凭借跨越几代人的经验,我们经验丰富的团队可以将您的塔恢复到最佳状态,使其性能超越原始规格。

专门的重建团队 | 拥有老塔的经验 | 从设计到安装到服务的整体解决方案 | 完整的项目管理选项 | 塔检查 | 紧急临时单位,最大限度地减少停机时间 | 拥有超过 30 名内部工程师 | 独资建筑公司——工会和非工会 | 超过 250 名 Marley 培训的工匠和技术人员

细节

完整的交钥匙体验

设计、工程、拆除和施工。

全面的产品

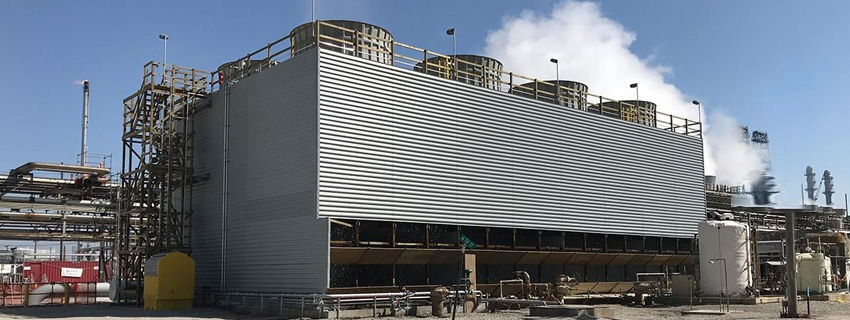

熟悉所有工厂类型——发电、炼油、石化、化工、制药、纸浆和造纸等。

几代人的经验

SPX 及其传统品牌在美国设计和建造了 95% 全自然通风冷却塔和超过 140,000 座机械通风冷却塔

卓越的安全性

经验修正率 (EMR) 始终卓越——低于 1.0。点击此处了解更多 SPX 安全资质。

模块化冷却塔

如果由于长时间停电、时间和生产力损失而无法进行重建,则可以考虑采用模块化方式建造新塔。Marley 预组装塔可以比现场安装的替代方案更快地交付 60% 并更快地安装 80%。

逆流 马利医学博士 Everest® 冷却塔 和横流 马利北卡罗来纳州珠穆朗玛峰冷却塔 为工艺冷却和工业应用带来巨大优势。这些更大、更高效的模块化结构可以提高单间冷却能力,同时与传统的现场安装冷却塔相比,将总占地面积减少 10% 至 30%。

有关模块化解决方案的更多信息, 访问我们的冷却塔网页.