可持续建筑项目的冷却塔

自然高效,自然凉爽。自然 Marley。

受到自然界诞生过程的启发, 蒸发式冷却塔因其节能潜力和低环境影响,是可持续建筑项目的理想散热解决方案。有效管理冷却塔水,最大限度地减少补给水和排污水量,也有机会获得水资源积分。即使在炎热干旱气候地区,例如中东大部分地区和美国西南部,蒸发式冷却系统也能为可持续建筑的设计、建造、运营和维护提供经济高效、节能的解决方案。

可持续建筑标准已从创新的例外发展成为许多社区的常态。如今,建筑设计师、工程师和管理人员期望暖通空调系统制造商能够投入研发资源,将环保的制冷系统商业化,使其在满足全球 ASHRAE、LEED 和其他可持续性标准的同时,提供卓越的性能和价值。

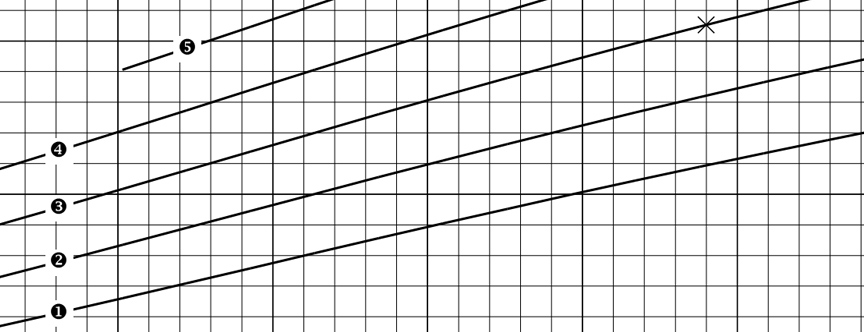

ASHRAE 90.1 开放式冷却塔最低能效

在热水温度95°F、冷水温度85°F、湿球温度75°F(35/29.5/23.9°C)的标准工况下,轴流式开放式冷却塔的流量为每马力40.2加仑/分钟(12.24立方米/小时/千瓦),离心式开放式冷却塔的流量为每马力20加仑/分钟(6.09立方米/小时/千瓦)。美国所有州都已针对舒适性冷却应用采用了这些或更严格的标准。Marley标准冷却塔型号流量范围为30至400加仑/分钟/马力。

对可持续建筑项目感兴趣吗?

填写下面的表格,与我们的可持续建筑专家联系!

常见问题

以下问答来自对 SPX Cooling Tech 内部和外部的工程师和冷却塔专家的调查,旨在更好地了解冷却塔如何成功地为可持续建设计划做出贡献。

最受认可的建筑可持续性认证计划有哪些?为什么它们很重要?

美国绿色建筑委员会 (USGBC) 制定并得到全球认可的能源与环境设计先锋奖 (LEED) 是一项评级体系,旨在评估和推广资源高效型建筑,以支持可持续的健康生活环境。LEED 认证体系要求建筑满足九个独立类别的要求,其中包括节水和节能,总分决定四个建筑认证等级之一。USGBC 还认可美国以外的超过 165 个国家和地区的环境标准,其中包括欧洲和中东地区一些在绿色建筑方面处于世界领先地位的社区。USGBC 网站表示:“人们知道,如果他们居住在获得 LEED 认证的建筑中,他们就能减少能源和水的消耗,避免浪费,节省维护成本,改善室内空气质量,为居住者提供舒适感,并减轻社区的环境负担。他们还知道,他们居住在一座能够增进健康和福祉的建筑中。如今,绿色建筑已发展成为一个价值万亿美元的产业,LEED 也已成为全球应用最广泛的绿色建筑项目。”

在暖通空调 (HVAC) 行业,LEED 是对美国采暖、制冷与空调工程师协会 (ASHRAE) 能效标准的补充。LEED 认证之所以受欢迎,是因为其由全球公认的第三方系统评级,能够反映建筑设计、施工和运行系统的整体卓越性和完整性。而 ASHRAE 传统上更侧重于暖通空调 (HVAC) 专用的建筑组件,例如安装在冷却塔上的百叶窗和除水器,用于防止水溅出并支持节水,或使用变频驱动器配合风扇电机来节能。

WELL 建筑标准™ (WELL) 是一个基于性能的体系,用于测量、认证和监测建筑环境中影响在建筑中生活、工作和学习的人们健康和福祉的特征。WELL 关注建筑性能的七个方面:空气、水、营养、光照、健身、舒适度和身心健康。WELL 建筑标准以循证研究为基础,这些研究证明了人们 90% 以上时间所处的建筑与其对使用者健康和福祉的影响之间存在关联。WELL 建筑标准由国际 WELL 建筑研究院™ 管理,并由绿色商业认证公司 (GBCI) 进行第三方认证。

另一项评级指南是英国建筑研究机构环境评估方法(BREEAM),该方法在整个欧洲都享有盛誉。BREEAM旨在评估、评级和认证建筑的可持续性,以减少建筑和开发对环境的负面影响。

循环经济(CE)是一个新兴概念,旨在指导全球商业和工业专业人士的最佳环境实践。CE 呼吁取代传统的线性经济模式——获取、制造、处置——并优化现有资源:尽可能长时间地利用它们,最大限度地挖掘其价值,并在产品和材料的初始使用寿命结束后,尽可能地进行回收和再生。

例如,马利® 不锈钢冷却塔的回收材料比例高达100%,一些镀锌钢冷却塔的回收材料比例甚至高达23%。退役后,钢材可以再次回收用于其他用途,这一循环符合循环经济的理念。

对于希望将蒸发冷却纳入建筑可持续性项目的建筑设计团队,需要进行哪些提前规划?

由于当今大多数建筑都采用某种方法来冷却室内空气,工程师和建筑师可能会寻求最高效、最环保的可持续方法。可持续性评级体系奖励那些节约能源、材料和水资源的环境可持续实践。以下是使用 LEED 体系的示例:

能够实现这些目标的蒸发式冷却塔系统有望获得 LEED 能源优化积分,其中现有建筑最高可获得 20 分,新建筑最高可获得 18 分。致力于优化能源性能的建筑设计团队可以通过实施 HVAC 相关策略和选择有助于提高能效的设备,完成一半的认证。建筑物至少获得 40 分即可获得 LEED 认证。

首先,要获得认证积分,建筑物必须满足一些先决条件。对于新建建筑,设计团队可以通过安装补给水表、电导率控制器、溢流报警器以及除水器来证明冷却塔对减少室内用水量的贡献。如果业主承诺进行水表计量、基础调试和验证,新建建筑也可以获得认证预审资格。

基本调试和验证包括实施“设施要求和运营计划”,该计划可能涉及设备运行时间表和优化能源使用的 HVAC 设定点。

冷却塔通过蒸发暖通空调系统(HVAC)的循环水来带走热量。只需少量水在系统中循环。蒸发式冷却塔中的水与气流混合——通常由风扇(通常使用变频驱动器以节省能源)产生;热水蒸发,产生冷却作用。

可以通过多种方式优化冷却塔运行,以直接促进 LEED 认证:

- 在非高峰时段以可变流量运行冷却塔,只要实现合理的水分配,就能通过降低流量和风扇能耗来提高效率。示例:

- 让一半的风扇全速运转,以一半的能耗实现 50% 的冷却效果。

- 以半速运转所有风扇,以八分之一的能耗实现 50% 的冷却效果。

- 监测用水量,找到减少用水的方法。如前所述,水表可以帮助现有建筑获得最多两分,新建筑获得最多一分。 Marley 用水量计算器 帮助建筑规划人员确定在特定应用中使用蒸发冷却可以节省多少水。

- 将水质管理、污染物控制和浓缩循环纳入系统节水体系。实现节水,现有建筑可获得最高三分,新建筑可获得最高两分。

最大限度地提高“浓缩循环”是推荐的节水措施。浓缩循环的定义是循环“排污水”中浓缩溶解固体与新鲜补给水中浓缩溶解固体的比率。增加浓缩循环可以同时大幅减少排污水和补给水,从而达到水化学平衡,既能节约用水,又能去除蒸发冷却过程中溶解的矿物质。

同时,必须严格控制溶解固体的含量。实施有效的水处理方案,并配备水质监测工具,使冷却塔操作员能够主动解决与微生物、腐蚀、水垢和节水相关的问题。

相对湿度如何影响蒸发冷却过程?为什么相对湿度在世界干旱地区如此重要?

相对湿度测量的是空气中实际水分含量与空气可容纳水分含量之间的差值。它指的是湿球温度(即空气中的水分含量)与干球温度(即室外温度)之间的差值。在相对湿度为100%时,湿球温度和干球温度相同。蒸发式冷却系统中,热量传递基于湿球温度,而干式冷却系统则依赖于干球温度。蒸发式冷却系统能够产生接近湿球温度的冷水,该温度通常低于室外干球温度,从而在干旱地区节省能源。另一方面,在中东等地区,干式冷却系统必须全年应对较高的干球温度。

在水资源有限或完全没有水资源的干旱气候条件下,混合冷却塔可能有助于减少用水量。干湿混合组件的组合可在高热负荷条件下最大限度地提高冷却效率,同时在低负荷条件下实现节水。采用干湿技术的创新混合产品——例如 马利 NCWD 冷却塔 – 首先将冷却水通过塔顶的干燥区,进一步节省用水,并增加获得创新积分的可能性。NCWD 塔每年可减少高达 20% 的用水量,具体取决于气候条件和设施的热负荷情况。

与风冷冷却系统相比,使用水冷冷却系统有哪些优势?

建筑运营商可以使用哪些冷却塔控制或组件来实现额外的节能?

建议将变频驱动器 (VFD) 与风扇配合使用。对于双速风扇电机,当需要超过 50% 的冷却能力时,需要将风扇功率提升至 100% 才能达到该水平。VFD 系统旨在将绝对温度控制与理想的能源管理相结合。冷却塔用户选择冷水温度,驱动系统将调节风扇转速以保持该温度。在大多数气候条件下,使用 VFD 可以显著降低年度能耗,因此对于注重能源效率和可持续性的项目而言,VFD 至关重要。

与变频器 (VFD) 配合使用时,永磁电机的节能效果可能与齿轮传动一样,但初始成本可能会显著提高。除了这两个因素外,建筑管理人员还应考虑维护的便捷性、可靠性和使用寿命,并与安装成本、运行复杂性和环境影响进行权衡。

冷却塔的尺寸如何影响节能?

体积更大的冷却塔效率更高,因为它们通常具有更大的传热介质(填料)体积,从而可以减少空气流量并降低风扇功率,从而提高节能效果。多种塔体尺寸和风扇功率的组合可以满足特定水流量下的特定温度要求。由于最大限度地节省能源通常需要使用更大且成本可能更高的冷却塔,因此系统设计师应咨询冷却塔制造商,以帮助他们权衡成本与功耗效益,从而找到最符合其需求的解决方案。

LEED 将 ASHRAE 90.1 能效标准设定为符合 LEED 评分标准的门槛。LEED 评分的授予取决于建筑整体能效的提升,且该提升优于 ASHRAE 90.1 标准。

选择物理尺寸较大、能效(加仑/分钟/马力)高于 ASHRAE 90.1 标准的冷却塔,有助于获得 LEED 认证。使用变频驱动器 (VFD) 还可以在大多数气候条件下实现显著的年度节能效果,这也有助于获得 LEED 认证。

我们的 塔的尺寸和选择 软件可以通过对每个选择的输出提供 ASHRAE 效率计算来帮助您。

什么是 ASHRAE 90.1?

我的冷却塔如何获得 LEED 认证和信用?

由于当今大多数建筑都采用某种方法来冷却室内空气,工程师和建筑师可能会寻求最高效、最环保的可持续方法。可持续性评级体系奖励那些节约能源、材料和水资源的环境可持续实践。以下是使用 LEED 体系的示例:

能够实现这些目标的蒸发式冷却塔系统有望获得 LEED 能源优化积分,其中现有建筑最高可获得 20 分,新建筑最高可获得 18 分。致力于优化能源性能的建筑设计团队可以通过实施 HVAC 相关策略和选择有助于提高能效的设备,完成一半的认证。建筑物至少获得 40 分即可获得 LEED 认证。

首先,要获得认证积分,建筑物必须满足一些先决条件。对于新建建筑,设计团队可以通过安装补给水表、电导率控制器、溢流报警器以及除水器来证明冷却塔对减少室内用水量的贡献。如果业主承诺进行水表计量、基础调试和验证,新建建筑也可以获得认证预审资格。

基本调试和验证包括实施“设施要求和运营计划”,该计划可能涉及设备运行时间表和优化能源使用的 HVAC 设定点。

冷却塔通过蒸发暖通空调系统(HVAC)的循环水来带走热量。只需少量水在系统中循环。蒸发式冷却塔中的水与气流混合——通常由风扇(通常使用变频驱动器以节省能源)产生;热水蒸发,产生冷却作用。

可以通过多种方式优化冷却塔运行,以直接促进 LEED 认证:

- 在非高峰时段以可变流量运行冷却塔,只要实现合理的水分配,就能通过降低流量和风扇能耗来提高效率。示例:

- 让一半的风扇全速运转,以一半的能耗实现 50% 的冷却效果。

- 以半速运转所有风扇,以八分之一的能耗实现 50% 的冷却效果。

- 监测用水量,找到减少用水的方法。如前所述,水表可以帮助现有建筑获得最多两分,新建筑获得最多一分。 Marley 用水量计算器 帮助建筑规划人员确定在特定应用中使用蒸发冷却可以节省多少水。

- 将水质管理、污染物控制和浓缩循环纳入系统节水体系。实现节水,现有建筑可获得最高三分,新建筑可获得最高两分。

最大限度地提高“浓缩循环”是推荐的节水措施。浓缩循环的定义是循环“排污水”中浓缩溶解固体与新鲜补给水中浓缩溶解固体的比率。增加浓缩循环可以同时大幅减少排污水和补给水,从而达到水化学平衡,既能节约用水,又能去除蒸发冷却过程中溶解的矿物质。

同时,必须严格控制溶解固体的含量。实施有效的水处理方案,并配备水质监测工具,使冷却塔操作员能够主动解决与微生物、腐蚀、水垢和节水相关的问题。

冷却塔的效率很大程度上取决于运行和维护标准,但气候也起着一定作用。当相对湿度较低时,例如在中东等炎热干燥的地区,蒸发冷却对建筑业主来说更为有利。

相对湿度测量的是空气中实际水分含量与空气可容纳水分含量之间的差值。它指的是湿球温度(即空气中的水分含量)与干球温度(即室外温度)之间的差值。在相对湿度为100%时,湿球温度和干球温度相同。蒸发式冷却系统中,热量传递基于湿球温度,而干式冷却系统则依赖于干球温度。蒸发式冷却系统能够产生接近湿球温度的冷水,该温度通常低于室外干球温度,从而在干旱地区节省能源。另一方面,在中东等地区,干式冷却系统必须全年应对较高的干球温度。

在水资源有限或完全没有水资源的干旱气候条件下,混合冷却塔可能有助于减少用水量。干湿混合组件的组合可在高热负荷条件下最大限度地提高冷却效率,同时在低负荷条件下实现节水。采用干湿技术的创新混合产品——例如 马利 NCWD 冷却塔 – 首先将冷却水通过塔顶的干燥区,进一步节省用水,并增加获得创新积分的可能性。NCWD 塔每年可减少高达 20% 的用水量,具体取决于气候条件和设施的热负荷情况。

与风冷冷却系统相比,使用水冷冷却系统有哪些优势?

是的,简单的解释是,风冷式暖通空调系统需要更高的风扇功率来降低温度,因此能源效率较低。风冷设备使用风扇,通过将空气吹过盘管表面来冷却流经盘管的流体,而这些风扇由电力驱动。根据所在地的气候条件,水冷系统可以实现显著的节能效果。根据 水力学产业联盟与风冷或变制冷剂流量 (VRF) 系统相比,使用水冷系统的建筑可以节省 5% 至 30% 或更多的 HVAC 能耗

建议将变频驱动器 (VFD) 与风扇配合使用。对于双速风扇电机,当需要超过 50% 的冷却能力时,需要将风扇功率提升至 100% 才能达到该水平。VFD 系统旨在将绝对温度控制与理想的能源管理相结合。冷却塔用户选择冷水温度,驱动系统将调节风扇转速以保持该温度。在大多数气候条件下,使用 VFD 可以显著降低年度能耗,因此对于注重能源效率和可持续性的项目而言,VFD 至关重要。

与变频器 (VFD) 配合使用时,永磁电机的节能效果可能与齿轮传动一样,但初始成本可能会显著提高。除了这两个因素外,建筑管理人员还应考虑维护的便捷性、可靠性和使用寿命,并与安装成本、运行复杂性和环境影响进行权衡。

体积更大的冷却塔效率更高,因为它们通常具有更大的传热介质(填料)体积,从而可以减少空气流量并降低风扇功率,从而提高节能效果。多种塔体尺寸和风扇功率的组合可以满足特定水流量下的特定温度要求。由于最大限度地节省能源通常需要使用更大且成本可能更高的冷却塔,因此系统设计师应咨询冷却塔制造商,以帮助他们权衡成本与功耗效益,从而找到最符合其需求的解决方案。

LEED 将 ASHRAE 90.1 能效标准设定为符合 LEED 评分标准的门槛。LEED 评分的授予取决于建筑整体能效的提升,且该提升优于 ASHRAE 90.1 标准。

选择物理尺寸较大、能效(加仑/分钟/马力)高于 ASHRAE 90.1 标准的冷却塔,有助于获得 LEED 认证。使用变频驱动器 (VFD) 还可以在大多数气候条件下实现显著的年度节能效果,这也有助于获得 LEED 认证。

我们的 塔的尺寸和选择 软件可以通过对每个选择的输出提供 ASHRAE 效率计算来帮助您。