马利医学博士

逆流冷却塔

所有型号均采用背对背安装配置 提供更多的场地布置适应性。现在有可选的机械检修平台,无论是工厂组装还是现场安装,都可以允许 安全访问 适用于机械系统、配水系统、填料和除雾器。Marley 和 MD 均通过了 CTI 热力及噪音认证,确保满足各种流量、温度和噪音要求。.

集会

品牌: 马利

配置

可用性:全球

容量

(61-515 立方米/小时)

热容量:89-756吨

(391-3323千瓦)

认证

CTI认证的热性能和噪声性能

符合 OSHA 标准

FM 批准

符合 ASHRAE 90.1 标准

经过 Eurovent 认证

细节

无与伦比的可靠性

重型结构、高性能设计和我们的五年机械保修确保在各种流量和温度要求下实现一致、完全额定的冷却。

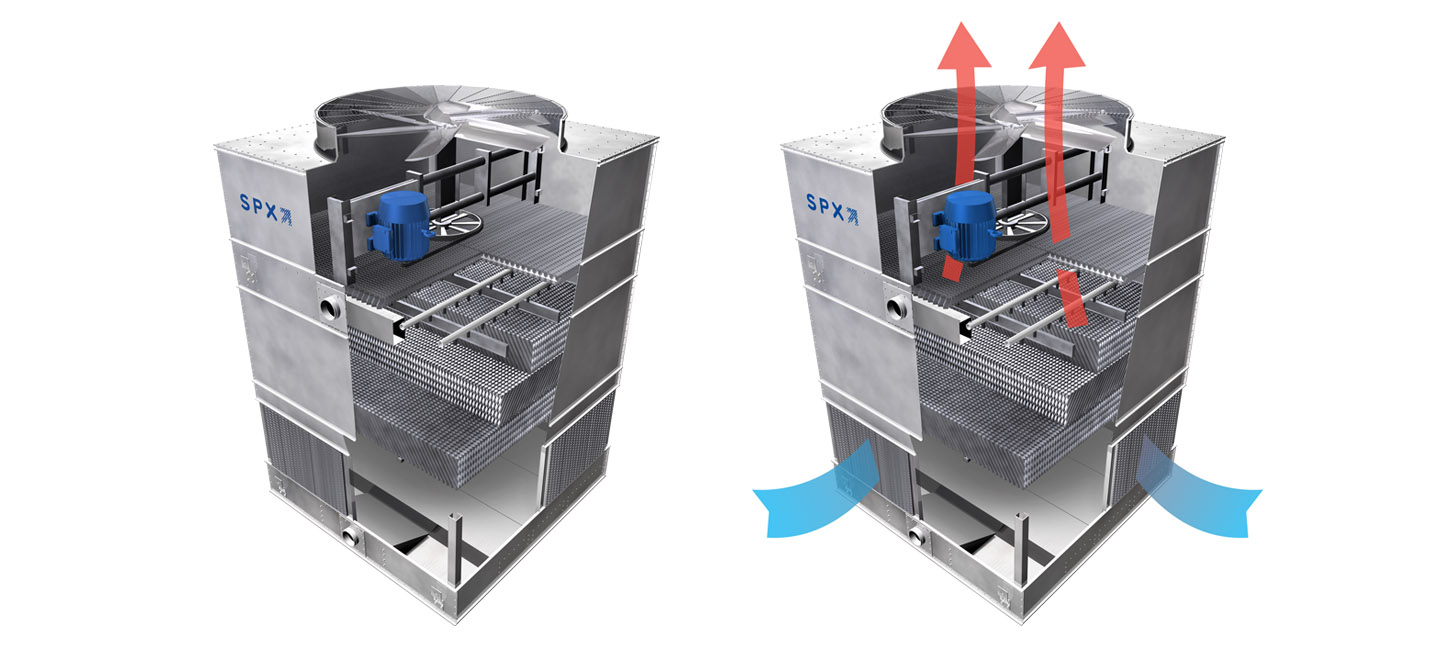

更小的占用空间

对于许多暖通空调和轻工业用途,诱导通风逆流冷却塔设计所需的平面面积比横流冷却塔要小。而且由于冷却塔的尺寸通常会导致钢材用量减少,因此其重量减轻,所需的支撑结构也更少。

低能耗

诱导通风逆流机械设备比离心风扇逆流冷却塔具有更低的风扇能量需求,从而最大程度地降低了能耗。

易于维护

SPX 冷却技术公司一直致力于解决逆流冷却塔长期以来存在的维护难题。我们的 MD 冷却塔提供更大的检修门、易于拆卸的块状填料和其他简化维护的功能。

低噪音

CTI 认证的 Marley MD 冷却塔标配我们的低噪音风扇,适用于大多数对噪音敏感的情况。有多种风扇和衰减选项可供选择,以满足更严格的噪音要求。

独立验证的声音数据

马利塔是 仅包装冷却塔 经第三方 CTI 授权测试机构和认证声学工程师按照 CTI ATC-128 测试代码进行测试。MD 声级为 经过独立验证 达到公布的噪音水平。

卓越的水管理

为了解决其他制造商的逆流冷却塔设计中常见的“溅出”问题,SPX 推出了业界首创的产品:三通入口百叶窗,可节约用水并改善冬季运行。

FM 认证

对于两个或多个单元的应用,MD 塔符合冷却塔的 FM 认证标准,等级编号 4930。

高效风扇 采用宽弦设计,以在低风扇尖端速度下实现最高效率。

缓入口风扇筒 确保全面积、低湍流的气流通过气缸。

调心滚子轴承 额定L10寿命为100,000小时。

TEFC 风扇电机 其服务系数为 1.15,可变扭矩和适用于冷却塔的特殊绝缘可延长使用寿命。

MD 空气流动包 包括结构支撑在内的所有部件均保证五年内不会失效。

供水系统

加压喷雾系统 将水均匀地分布在填充物上。

低堵塞 聚丙烯喷嘴可将水精确地分配到填充区域。

马利 MC 热成型 PVC 薄膜填料组装成包,便于拆卸和清洁。低堵塞薄膜填料也可用于脏水应用。

马利 XCEL 漂移消除器将漂移损失限制在设计流量的 0.001% 以下。

结构

诱导通风逆流 设计所需的平面面积可能比横流冷却塔通常使用的面积要小。

钢结构 为重型镀锌钢结构标准。300 系列不锈钢可选。

工厂装配 确保高效的现场安装。

三重通行 入口百叶窗限制溅出并阻止阳光进入冷却塔集水盆。

增值选项

Marley System 5 减速器驱动 – 整整五年内无需换油,是业内最低的维护要求。换油次数减少可减少废物流和环境影响。独立测试证明,Marley Geareducer 比其他冷却塔制造商使用的变速箱安静 12 dBA。

焊接不锈钢集水盆 – 为了提供额外的保护,所有暴露在循环水中的集水盆部件(包括伸入水盆的结构构件)和所有水盆选件均采用厚规格 300 系列不锈钢。

机械检修门平台 – 钢结构和格栅与冷却塔连接并由冷却塔支撑,便于进入机械系统、除水器、分配系统和填料。可由工厂组装或现场安装。

超静音风扇 – 宽弦声学几何风扇可最大程度提高效率,同时显著降低噪音水平。风扇由轻质耐用、耐腐蚀和防火的海洋级铝制成。

声音衰减 – 集水盆内安装的防溅衰减介质可有效且经济地降低落水噪音。还可提供风扇出口衰减。

低堵塞薄膜填充 – 此选项为脏水应用提供更高程度的抗堵塞能力。

盆地清扫器管道 – 工厂安装的清扫管道有助于限制集水盆中的污垢和碎片堆积,增强系统过滤。

控制系统 – 复杂程度范围从标准风扇启动器和断路器到与您的建筑或过程系统协同工作的可编程逻辑控制器。

变速驱动 – 提供极致的温度控制、能源管理、声音控制和机械设备寿命。

固态水位控制包 – 监测水盆水位。可选配置包括补水、高水位报警、低水位报警、高水位和低水位切断以及电水盆加热器切断。

电盆加热器 – 不锈钢电浸入式加热器采用磁性接触器和固态电路板,有助于防止寒冷天气下结冰。

感谢您最近从 SPX Cooling Technologies, Inc. 购买产品。我们十分重视您的业务,并期待将来能为您服务。

注册 SPX 产品的好处:

你有权这么做! 您的产品安装已验证且保修已激活。

您已收到通知! 您会立即收到重要产品信息和服务警报的通知。

你也包括在内! 您将收到独家教育节目和活动的邀请,包括 School of Cool® 塔维护车间。

我们听到了您的声音! 我们在客户心声调查中征集了您对我们的产品、服务、技术支持和编程的意见。

将适用 SPX Cooling Technologies 的有限保修条款。有关保修范围的完整详情,请参阅产品随附的保修证书。

填写以下表格以注册您的产品。请确保提供的信息准确无误 – 为了注册您的产品,所有字段都是必填项。