馬利 MH 閉式冷卻水塔

蒸發冷卻水塔

品牌: 馬利 |產品類別: 蒸發冷卻水塔

產品詳情:

可用性: 全世界

Tonnage Range: 78- 628

CTI認證

歐洲通風口認證

FM Approval Option

Copper Coil Models Now Available!

Expanded Product Offering!

The popular Marley MH Fluid Cooler line has been expanded to include two new model sizes providing even greater range of performance.

MH 閉式冷卻水塔仍然是最高效的系統之一,也是工業和 HVAC 閉環應用的最佳選擇。透過將製程流體保持在清潔、閉環中,並將冷卻水塔和熱交換器的功能組合到一個系統中,MH 閉式冷卻水塔可提供卓越的操作和維護優勢。

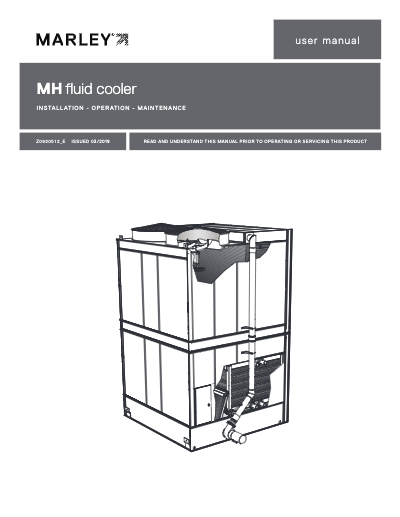

混合設計

MH 閉式冷卻水塔採用填充介質和底盤管的組合,與傳統閉路冷卻器相比,性能顯著提高。

- 過程流體透過線圈內部泵送

- 當循環水流過盤管外部時,熱量從製程流體傳遞到循環水

- 加熱後的循環水從集水池抽至重力分配池

- 一小部分循環水均勻分佈在填充介質和盤管上,被蒸發,有效地將熱量排放到大氣中

正確的選擇

The Marley MH Fluid Cooler is one of the most energy efficient closed circuit systems on the market and a great choice for closed loop Industrial and HVAC applications.

- 新的!銅線圈型號: Select models are now available with copper coils, offering superior corrosion resistance, improved heat transfer, reduced operating weight and numerous other benefits.

- 最大效率: 混合設計和高效組件以低輸入功率提供一致、可靠的冷卻。

- Space Saving Footprint: With higher capacity per footprint than conventional closed circuit designs, the MH Fluid cooler is a great fit for applications with space restrictions.

- 無與倫比的可靠性: 重型結構由我們的 5 年機械保固提供支持,可幫助您的流程年復一年順利運作。

- 認證性能: 標準型號的熱容量由冷卻技術研究所針對水、乙二醇溶液和丙二醇溶液的性能進行獨立認證。

- Low Sound Operation: Equipped with low-sound fans as standard, the MH Fluid Cooler is suitable for most noise sensitive situations. Multiple fan and attenuation options are now available to meet more stringent sound requirements.

- 可選乾燥能力: 這些型號可配備可選的擴展表面線圈,用於在寒冷環境條件下進行部分負載乾操作。

CoolBoost Technology

The Marley MH Fluid Cooler uses mechanical, induced-draft, crossflow technology and fill media located above the coil.

The Marley MH Fluid Cooler uses mechanical, induced-draft, crossflow technology and fill media located above the coil.

-

The CoolBoost Process

- Process fluid is pumped internally through the coil.

- Recirculating water is cooled as it passes over the fill media and redistributed over the outside of the coil.

- A small portion of recirculating water is evaporated by air drawn through the coil and fill media, cooling the process fluid.

- The coil section rejects heat through evaporative cooling using the fresh air stream and pre-cooled recirculating spray water.

- Recirculated water falls from the coil into collection basins and is then pumped back up to be distributed over the fill media.

CoolBoost Benefits

Protects process fluids from contamination.

Maximizes system efficiency by reducing fouling and scaling tendencies.

Reduces system energy and maintenance costs.

Conserves valuable space in equipment rooms.

Provides reliable, efficient, year-round operation.