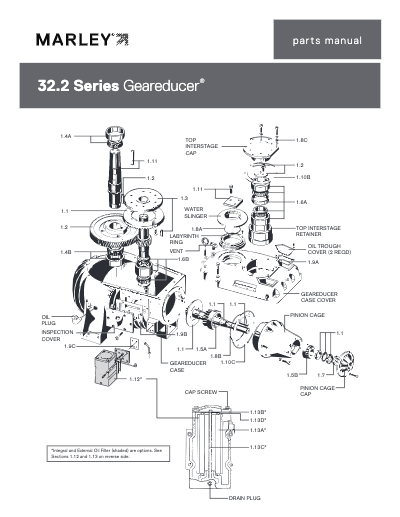

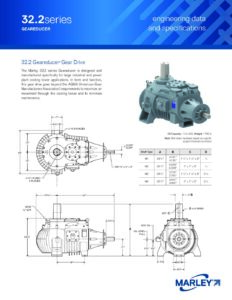

减速机® – 双重减少

冷却塔部件

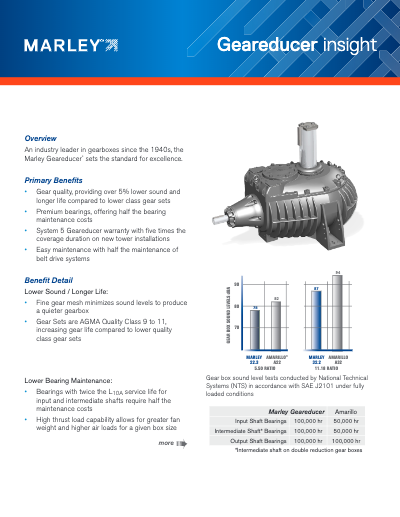

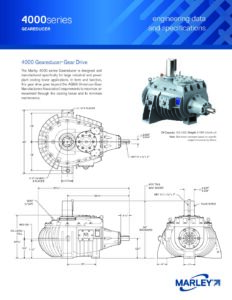

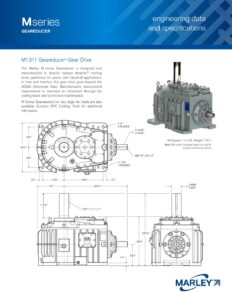

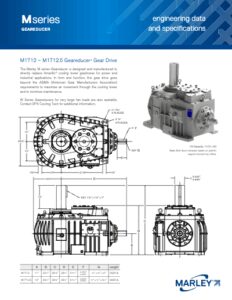

Marley 工业齿轮箱是专门为冷却塔制造和设计的 大型工业 和 发电厂应用。其设计在形状和功能上都超出了正常的 AGMA 要求——既能最大限度地促进塔内的空气流动,又能最大限度地减少维护的影响。

尽管减速机的主要功能是将驱动器(通常是电动机)的速度降低到有利于风扇良好性能的速度,但它也必须满足其他标准。例如,它必须为风扇提供主要支撑 - 承受启动时和随后的速度变化期间施加的冲击负载 - 固定风扇以防止其在旋转力的作用下发生横向运动 - 并尽可能减少功率传输损耗以及噪音的产生。

鉴于这些要求,许多机械设备制造商都提供可接受的减速器。这些设备专为更宽容的商业应用而设计,通常无法应对冷却塔服务的严苛和特殊性,例如在极其潮湿的环境中运行(通常是间歇性的)的腐蚀作用。因此,这些商用减速器的预期寿命以及安装它们的冷却塔的热性能通常都会受到影响。

Marley 是唯一一家专门为冷却塔服务而设计的减速机的主要制造商。而且,由于我们不仅保证减速机的质量,还保证其所运行的冷却塔的热性能,因此我们非常重视开发、设计和制造。这创造了无与伦比的无故障运行历史。