馬利 MH 閉式冷卻水塔

蒸發冷卻水塔

品牌: 馬利 |產品類別: 蒸發冷卻水塔

廣受歡迎的 Marley MH 封閉式冷卻水塔系列 擴大 包括兩個新的型號尺寸,提供 更大的性能範圍.

MH 閉式冷卻水塔仍然是最高效的系統之一,也是工業和 HVAC 閉環應用的最佳選擇。透過將製程流體保持在清潔、閉環中,並將冷卻水塔和熱交換器的功能組合到一個系統中,MH 閉式冷卻水塔可提供卓越的操作和維護優勢。

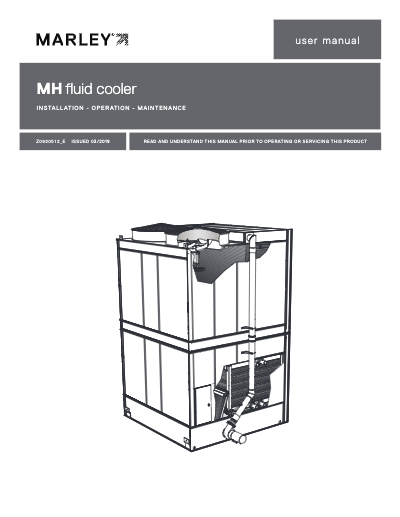

混合設計

MH 閉式冷卻水塔採用填充介質和底盤管的組合,與傳統閉路冷卻器相比,性能顯著提高。

- 過程流體透過線圈內部泵送

- 當循環水流過盤管外部時,熱量從製程流體傳遞到循環水

- 加熱後的循環水從集水池抽至重力分配池

- 一小部分循環水均勻分佈在填充介質和盤管上,被蒸發,有效地將熱量排放到大氣中

正確的選擇

Marley MH 閉式冷卻水塔是市場上最節能的閉式迴路系統之一,也是閉式工業和 HVAC 應用的絕佳選擇。

- 新的!銅線圈型號: 現在,部分型號配備了銅盤管,具有卓越的耐腐蝕性、改進的傳熱性能、減輕的工作重量以及許多其他優點。

- 最大效率: 混合設計和高效組件以低輸入功率提供一致、可靠的冷卻。

- 節省空間佔地面積: 與傳統的閉路設計相比,MH 閉式冷卻水塔的單位面積容量更高,非常適合空間有限的應用。

- 無與倫比的可靠性: 重型結構由我們的 5 年機械保固提供支持,可幫助您的流程年復一年順利運作。

- 認證性能: 標準型號的熱容量由冷卻技術研究所針對水、乙二醇溶液和丙二醇溶液的性能進行獨立認證。

- 低噪音操作:MH 閉式冷卻水塔標配低噪音風扇,適用於大多數噪音敏感的情況。現在可提供多種風扇和衰減選項,以滿足更嚴格的聲音要求。

- 可選乾燥能力: 這些型號可配備可選的擴展表面線圈,用於在寒冷環境條件下進行部分負載乾操作。

CoolBoost 技術

Marley MH 閉式冷卻水塔採用機械、誘導通風、橫流技術和位於盤管上方的填充介質。

Marley MH 閉式冷卻水塔採用機械、誘導通風、橫流技術和位於盤管上方的填充介質。

-

CoolBoost 工藝

- 過程流體透過線圈內部泵送。

- 循環水在流過填充介質時被冷卻並重新分佈在盤管的外部。

- 一小部分循環水被通過盤管和填充介質的空氣蒸發,從而冷卻過程流體。

- 盤管部分使用新鮮空氣流和預先冷卻的循環噴水透過蒸發冷卻來散熱。

- 循環水從盤管落入收集池,然後被泵回並分佈在填充介質上。

CoolBoost 的優點

保護 製程流體免受污染。

最大化 透過減少結垢和結垢傾向來提高系統效率。

減少 系統能源和維護成本。

儲存 設備間的寶貴空間。

提供 可靠、有效率、全年運作。