Recold JT

Forced Draft Cooling Tower

Product Details:

Availability: Worldwide

GPM Range: 20 – 2500

26 – 364 tons per cell

G235 galvanized steel construction

Optional series 300 stainless steel construction

What is a cooling tower?

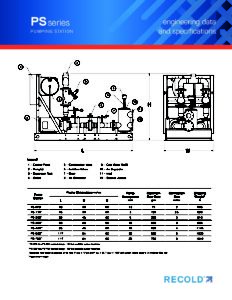

The Recold JT is a low profile, forced draft cooling tower that is ideal for height limited installations.

Combined with its centrifugal, ‘blower’ style fan, it is the perfect indoor fit where ceilings are low, ducting is required, and noise is unacceptable.

System

The process water enters the spray tree at top of the cooling tower, is sprayed down onto the heat exchanger surface or fill, giving up heat to the counterflowing air before returning to the system from the sump pan. Moist air does not enter the fan assembly, resulting in longer life and fewer service problems. Recold solves this problem with the wetted surface downstream of the fan assembly.

Hydro Spray Nozzles

Hydrospray Nozzles are made of non-ferrous material, sized and spaced for optimum wetting of decking. The even distribution of spray across the decking material is extremely important in evaporative equipment.

Accessibility

Recold Cooling Towers are designed for maximum accessibility for inspection and cleaning. Recold patented access doors on both sides of the cooling tower provide ample access to spray nozzles, decking, eliminators, bleeds and sump pan for service and maintenance. Recold access doors provide a complete air and water tight seal without gaskets or fasteners, are “quick opening”.

Blowers

A single slow-speed forward curve blower is used for optimum efficiency and minimum noise. Recold standardized on slow speed forward curve fans when tests indicated that propeller fans were too noisy for most commercial air conditioning systems. The lower cost of propeller fans can seldom be justified where noise is undesirable. Each blower is balanced to eliminate unit vibration on Recold’s high precision electronic balancing equipment. Large blowers are made from galvanized steel and subject to careful quality control throughout. Fan shafts are coated to prevent corrosion. The blower drives are selected at 150% of rated bhp.

Bearings are self-aligning ball-bearing type, with external lubricating fittings and selected for 200,000 hour average bearing life. Rugged, OSHA approved, belt guard and screen are provided for protection. Motor is mounted on adjustable base.

Drift Eliminators

Eliminators are constructed of PVC assembled in removable, easy to handle sections. A three break design allows three changes in air flow. The use of durable plastic eliminates the corrosion problems associated with galvanized eliminators.

Integrated Assembly

Recold Cooling Towers are completely assembled at the factory and shipped as a unit.

Fill

High efficiency is accomplished by using a PVC fill design that provides the maximum of wetted surface within allowable airside pressure drops. Fill units are conveniently sized for easy removal. Cooling tower fill shall be high efficiency, of self-extinguishing Polyvinyl Chloride (PVC), a minimum of 40 mils thick. It shall have a flame spread rating of 25 per ASTM standard E-84 and be impervious to rot, decay, fungus or biological attack.

Testing

All Recold Cooling Towers are tested under the close supervision of the Quality Control Department before being released for shipment. Fans are run and spray systems operated to assure quiet, balanced operation without leaks, water carryover or vibration. Nozzles are checked for proper distribution.

Capacity Controls

All Recold cooling towers are provided with a special damper in the discharge section of the blower scroll. This damper is standard equipment which is locked in place to act as a flow control vane.

If automatic control is required, the damper is unlocked and the damper rod is connected to a damper motor. This work should be factory installed and adjusted under good inspection supervision to assure proper operation.

The damper is controlled by a thermostat in the sump water. The water temperature is maintained above a predetermined level. As the water temperature drops the damper closes – in extreme weather closing completely. The fan is stopped by a limit switch on the controller. As water temperature increases the fan starts and the damper opens.

Thank you for your recent purchase from SPX Cooling Technologies, Inc. We appreciate your business and look forward to serving you in the future.

Benefits of Registering Your SPX Product:

YOU’RE WARRANTED! Your product installation is verified and warranty is activated.

YOU’RE NOTIFIED! You receive immediate notification of important product information and service alerts.

YOU’RE INCLUDED! You receive invitations to exclusive educational programming and events, including School of Cool® tower maintenance workshops.

WE HEAR YOU! Your opinions about our products, services, technical support and programming are requested in voice-of-customer surveys.

SPX Cooling Technologies’ limited warranty terms will apply. For full details of your warranty coverage, please see the warranty certificate included with your product.

Complete the form below to register your product. Please make sure the information provided is accurate – all fields are required in order to register your product.