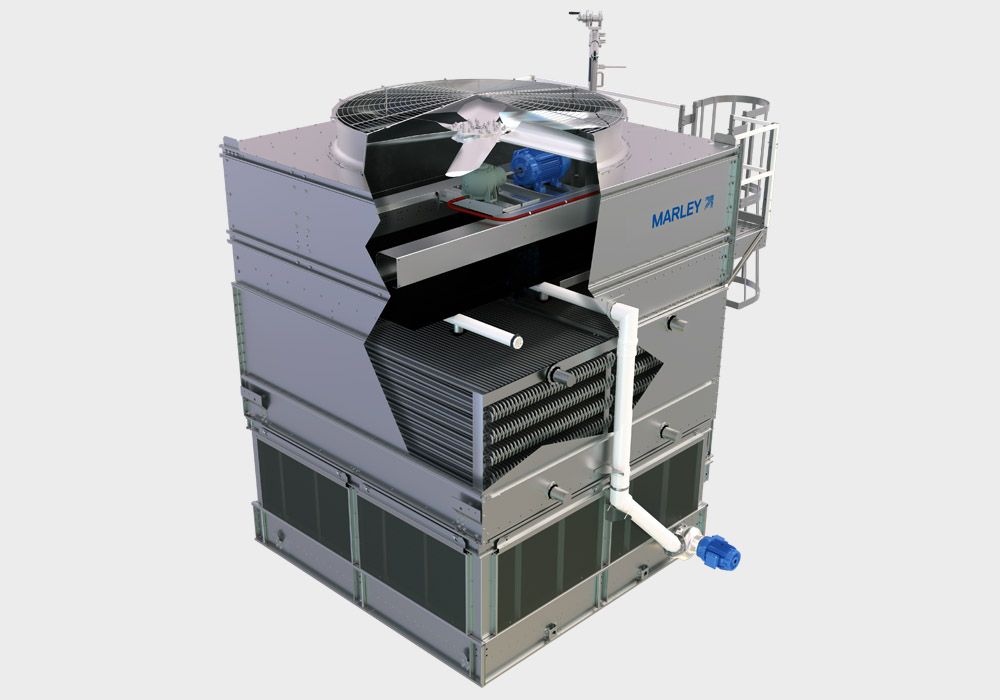

Marley DT Fluid Cooler

Evaporative Fluid Cooler

Product Details:

Induced Draft Counterflow Closed Circuit Fluid Cooler

Availability: Worldwide

Thermal Capacity: 58 – 321 tons (255 – 1411 kW) per cell

Flow Range: 80 – 1800 gpm (18 – 409 m3/hr) per cell

New Aero-X Coil Technology

Higher Dry Switch Point*

Lower Fluid Pressure Drop

CTI Certified

ASHRAE 90.1 Compliant

OSHA compliant

Now Featuring The Highest Nominal Cooling Capacity Per Footprint

Among Bare-Tube Coil-Only Fluid Coolers

An induced-draft, coil only closed-circuit cooling tower, the Marley® DT Fluid Cooler with Aero-X™ coil technology provides dry operation flexibility that fill/coil hybrid coolers cannot.

Aero-X Coil Technology Maximizes Thermal Capacity Per Footprint*

The lowest air-side pressure drop (up to 10% more airflow at the same fan HP) and highest nominal heat rejection capacity per footprint – benefits realized with the DT Fluid Cooler’s Aero-X coil technology – provide opportunities to reduce equipment size and/or lower energy consumption, while maintaining the dry operation flexibility that coil-only closed circuit coolers are known for.

Higher Dry Switch Point – Up To 10F+ Higher*

Whether the motivation for seasonal dry operation is to reduce site water usage, minimize water treatment costs or simplify operation in freezing conditions, higher dry switch point temperatures enable achievement of those objectives a larger portion of the year. With up to 10°F + higher dry switch point, the DT Fluid Cooler may enable up to 15-20% incremental annual hours in dry mode. Annual water savings per cooling ton of 3,000 gallons/ton and $40/ton are achievable in many areas, depending on climate conditions. Optional finned coils further enhance dry operation capability at higher ambient temperatures.

Lower Fluid Pressure Drop – Up To 30%

Reduced pumping energy requirements compared to the previous generation positively impact system operating cost and energy consumption.

Finned Coil Option – Now with Aero-X Coil Technology!

Optional Aero-X finned coil further enhances dry operation capability at higher ambient temperatures and boosts evaporative performance. Offers up to 20°F higher dry bulb switch point and up to 30% evaporative performance increase compared to similar bare-tube coil models.

*Nominal capacity vs other bare-tube coil-only fluid coolers

Genuine Marley mechanical system offers low maintenance costs and reliable performance with 5-year warranty. Belt drive optional.

Broad Product Selection

Choose from DT models in a wide range of sizes and layouts to meet your specific cooling requirements.

Robust Construction

Strong galvanized steel houses high-quality mechanical and heat transfer systems. Stainless steel component options, including water collection basin and bare tube heat transfer coils, allow customization to address the most demanding environmental conditions and extend service life.

Triple-pass air inlet louvers

Removable louvers incorporate three changes in direction to control splash out and sunlight exposure to limit algae growth.

Clog-Resistant Spray System

Large orifice spray nozzles help prevent debris build-up and clogging.

High Efficiency Axial Fan

Adjustable pitch fan blades permit the maximum utilization of rated horsepower and optimal cooling tower performance.

Premium Efficiency Fan Motor

The TEFC 1.15 service factor motor is designed to Marley specifications and specially insulated for humid cooling tower conditions.

PVC Drift Eliminators

High-efficiency, triple-pass PVC eliminators limit drift losses and are easily removed for inspection.

Large Access Door

Door provides convenient access to mechanical system, drift eliminators, water distribution system and heat transfer coils.

Sound Reduction

The CTI-certified DT Fluid Cooler comes standard with a Marley low-sound fan. Multiple fan and attenuation options are available to meet more stringent sound reduction requirements.

Marley Reliability

Heavy-duty construction, galvanized and stainless steel material options, high-performance design and our five-year mechanical warranty ensure consistent cooling over a wide range of closed-circuit cooling applications.

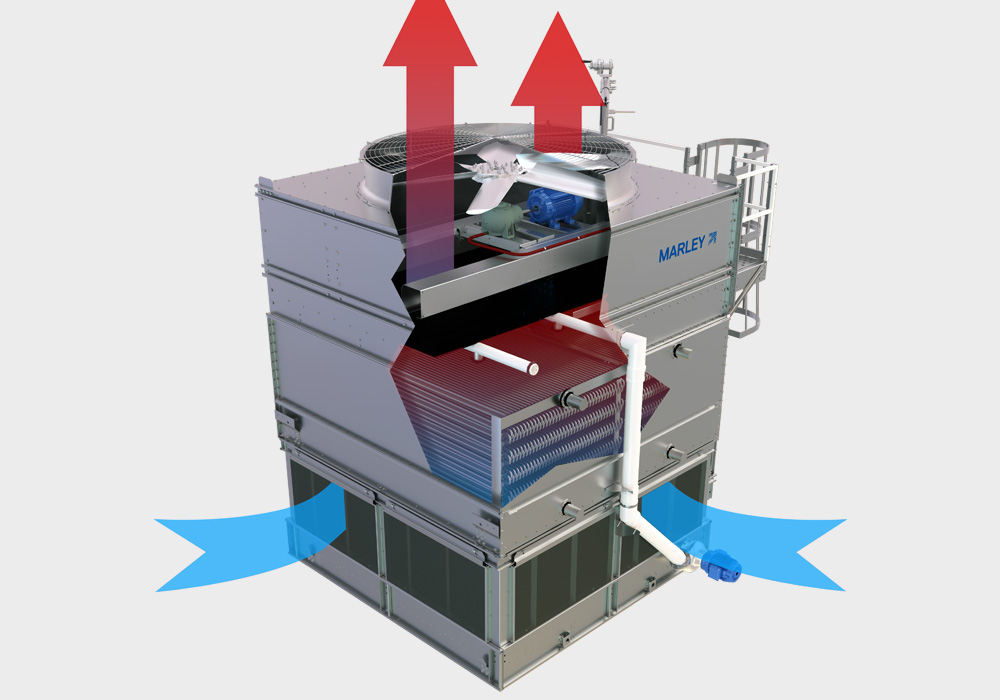

2. Recirculating water is pumped from the collection basin to the pressurized distribution system and is evenly distributed over the coils.

3. Heat is transferred from the process fluid to the recirculating water as it flows over the outside of the heat transfer coils.

4. Air induced through the fluid cooler evaporates a small portion of the recirculating water, rejecting heat to the atmosphere.