Field-Erected Cooling Towers

for higher heat loads- Power generation

- Oil and chemical refining

- Heavy manufacturing and industrial operations

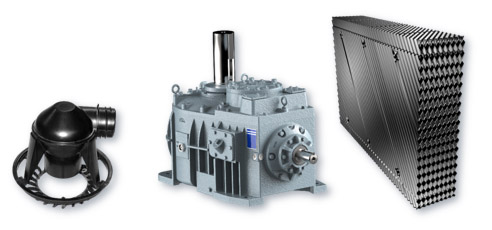

Marley field-erected cooling towers are available in both crossflow and counterflow designs, in a range of cell sizes, fill air travels, and fill heights to achieve optimum performance and operating economy. SPX design engineers review the owner’s specifications to optimally satisfy the fan horsepower, pump head, plan area, and other evaluation parameters to ensure that selected components work together efficiently. Computer modeling maximizes cooling from a given tower cell size for each set of design performance conditions.

Operational Stability

Engineering resources are fully engaged to support your repair, reconstruction and new tower erection needs.

Construction Safety

Components Inventory and Service

Call on SPX Cooling’s rapid-response field service crews to conduct cooling tower inspections, repair and reconstruction projects. /marley-parts-service-facility/

More Resources:

Regardless of your experience with cooling tower reconstruction, a review of industry best practices will help ensure your success. Read More…

When planning and evaluating a cooling tower repair and maintenance program, few cooling tower owners and operators conduct a thorough economic evaluation. Read More…

After many years of operation, cooling towers may require more than routine maintenance and component replacement to achieve the thermal performance necessary to support plant processes Read More…

Advance your evaporative cooling knowledge through this and other recorded webinars presented by SPX Marley technical experts. Register now:

To speak with someone immediately, call 1-800-4-Marley.