Electronically Commutated

(EC) Motor

Cooling Tower Parts

Some SPX Cooling Technologies products with low hp requirements include electronically commutated (EC) motors. Cooling towers that use high-efficiency EC motors usually have smaller capacity and footprint with a maximum application size of 10 hp or one-meter fan diameters.

SPX Cooling provides the EC motor as standard on the Marley® LW Fluid Cooler, Recold® LC Evaporative Condenser, and the Marley and Recold OlympusV Adiabatic Cooling Systems.

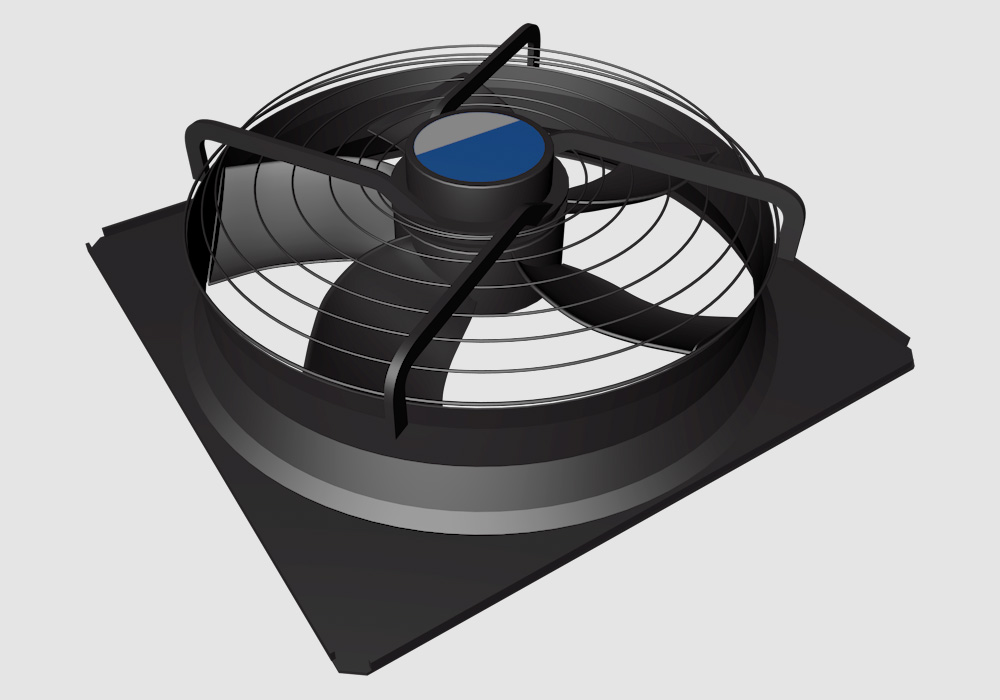

The EC motor combines a small DC motor and an inverter/speed controller into one compact package. The rotor portion of the motor typically uses rare earth permanent magnets and the integral speed control eliminates the need for an external VFD. For cooling tower applications, the fan, fan shroud and fan guard are often incorporated to provide a complete mechanical drive package. This provides a simple and compact arrangement that is easy to install in the factory and to replace in the field if ever needed.

Compared to belt drives and other low-horsepower motors (less than 5 hp), EC motors are consistently more efficient. In small-hp applications, the EC motor presents no power transmission loss while other low-hp motors and belt drives can experience power transmission losses from 5-20 percent.

Because EC motors use sealed bearings, there is virtually no maintenance. Serrated fan blades also result in the EC motor’s value as a low-sound power transmission technology. All EC motors include a five-year warranty.