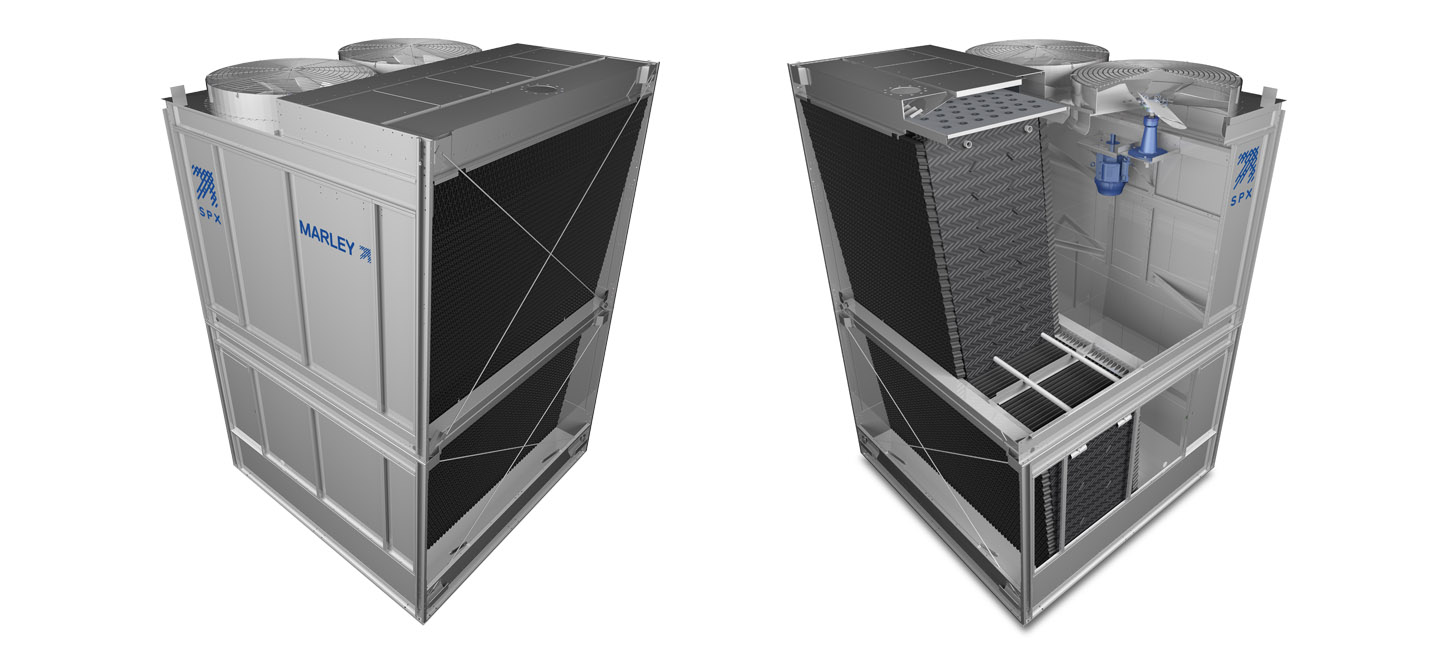

Marley AV

Crossflow Cooling Tower

Introducing the AV6800 consisting of 3 single height models and 2 double height models extending the product tonnage from 390 to 772 tons at standard conditions.

The factory-assembled Marley AV cooling tower is designed to minimize your costs and maximize your cooling tower performance through quick, easy installation and low maintenance operation. Its single flow, induced draft crossflow design offers you energy savings in a small footprint installation, making it an excellent crossflow cooling tower replacement for some forced draft counterflow cooling tower installations.

Assembly

Brand: Marley

Configuration

Availability: Worldwide

Capacity

(85-526 m3/hr)

Thermal Capacity: 125-772 tons

(550-3394 m3/hr)

Certifications

ASHRAE 90.1 compliant

OSHA compliant

AV Water Distribution System

Gravity flow distribution system. Easy, nonrestrictive maintenance. Basin covers are standard.

Marley Spiral Target polypropylene nozzles for consistent, predictable water distribution.

Marley MX75 thermoformed PVC film fill is suspended from the upper cooling tower structure by heavy galvanized steel support members providing clearance between fill and sloping self-cleaning collection basin floor for easy basin cleaning. Integral eliminators and louvers keep circulating water confined to fill over a wide range of air flow rates.

AV Structure

Crossflow configuration — easier and safer to inspect, service and maintain.

G-235 heavy galvanized steel. Also available in 300 series stainless steel.

Factory-assembled modules, including fan cylinders — makes final field installation hassle-free.

Large access doors — the generous plenum region in the AV cooling tower is non-confining, permitting quick visual inspection of cold water basin, internal structure, drift eliminators and mechanical equipment.

AV Air Movement System

Heavy duty aluminum alloy fan– adjustable pitch blades.

7.5 hp and larger fans are driven by a high quality, solid backed, multi-grooved neoprene and polyester v-belt thru a corrosion resistant aluminum alloy fan sheave.

Heavy duty, self-aligning, grease lubricated roller bearings selected with an L10 design life of 50,000 to 100,000 hours support the fan and shaft.

TEFC fan motor, 1.15 service factor, variable torque design, specially insulated for cooling tower duty.

The AV air movement system is guaranteed against failure for a period of five full years from date of shipment. Includes fan, fan shaft, bearings and mechanical equipment support.

Key Benefits

Ideal replacement Designed to easily replace forced draft blower cooling towers or other space sensitive installations.

Low energy costs Highly efficient propeller fans consume half the energy of blowers. And, gravity water distribution provides further savings thru lower total pump head.

Easy access Large, 23″ x 52″ access doors on both endwalls and “stand-up? plenum area help make the AV easy to service with generous access to the basin and mechanical equipment. No •paint can lid? access hatches.

Low piping costs Single inlet connection for easy and fast installation.

Long life Rugged G-235 galvanized steel frame, quality factory assembly. (Optionally available in 300 series stainless steel.)

All season reliability Integral louvers eliminate splash-out so cooling towers operate virtually ice-free in the winter.

Real world design Designed for severe wind, seismic, shipping, operating and live loads.

Tough MX75 high-performance fill Highly efficient cellular drift eliminators and honeycomb louvers integrally molded within the fill sheets.

Aluminum-alloy axial fan Adjustable-pitch fan blades permit maximum utilization of rated horsepower • allows field adjustment to optimize tower performance.

Rugged fan motor TEFC 1.15 service factor, severe duty, cast iron motor designed to Marley specifications for cooling tower duty. Specially insulated for extra protection from moisture.

Five-year mechanical warranty Five-year mechanical equipment warranty.

Stainless Steel Distribution Basin

Corrosion is usually most aggressive in the hot water distribution basins—stainless steel provides assurance of long, trouble-free service life.

Marley Control System Package

Factory-wired, factory-installed, factory-tested control center in NEMA 3R enclosure mounted on cooling tower casing near access door. Complete with thermostat controller for single or two-speed motors to maintain chosen cold water temperature.

Inlet Trash Screens

Factory-installed, U-edged, galvanized wire mesh screens work in concert with the internal cellular louvers.

External Service Platform

Provides easy access to distribution system without increasing installed height of cooling tower. Platform with OSHA guardrails is Factory Mounted, eliminating installation labor cost and time. Field-installed ladder with optional safety cage for easy access.

Welded Stainless Steel Collection Basin

All collection basin parts in the wetted area— including structural members projecting in the basin, assembly and attaching hardware, and all basin options, are heavy-gauge Series 300 stainless steel.

Thank you for your recent purchase from SPX Cooling Technologies, Inc. We appreciate your business and look forward to serving you in the future.

Benefits of Registering Your SPX Product:

YOU’RE WARRANTED! Your product installation is verified and warranty is activated.

YOU’RE NOTIFIED! You receive immediate notification of important product information and service alerts.

YOU’RE INCLUDED! You receive invitations to exclusive educational programming and events, including School of Cool® tower maintenance workshops.

WE HEAR YOU! Your opinions about our products, services, technical support and programming are requested in voice-of-customer surveys.

SPX Cooling Technologies’ limited warranty terms will apply. For full details of your warranty coverage, please see the warranty certificate included with your product.

Complete the form below to register your product. Please make sure the information provided is accurate – all fields are required in order to register your product.