Marley MD Everest

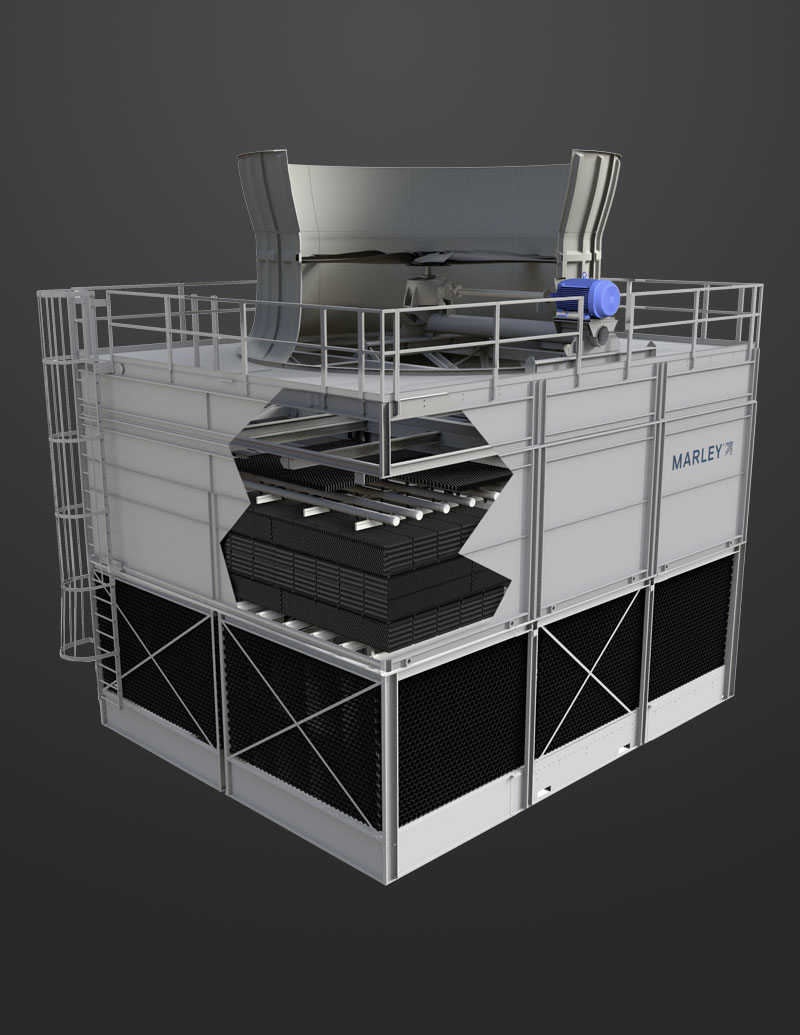

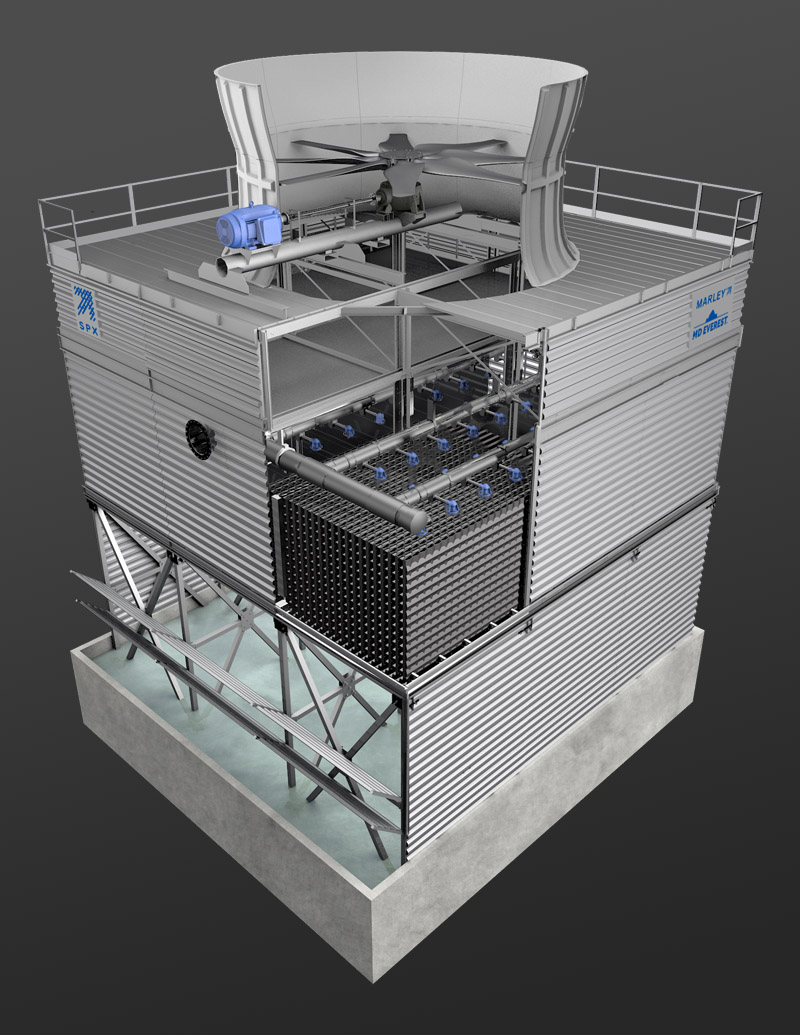

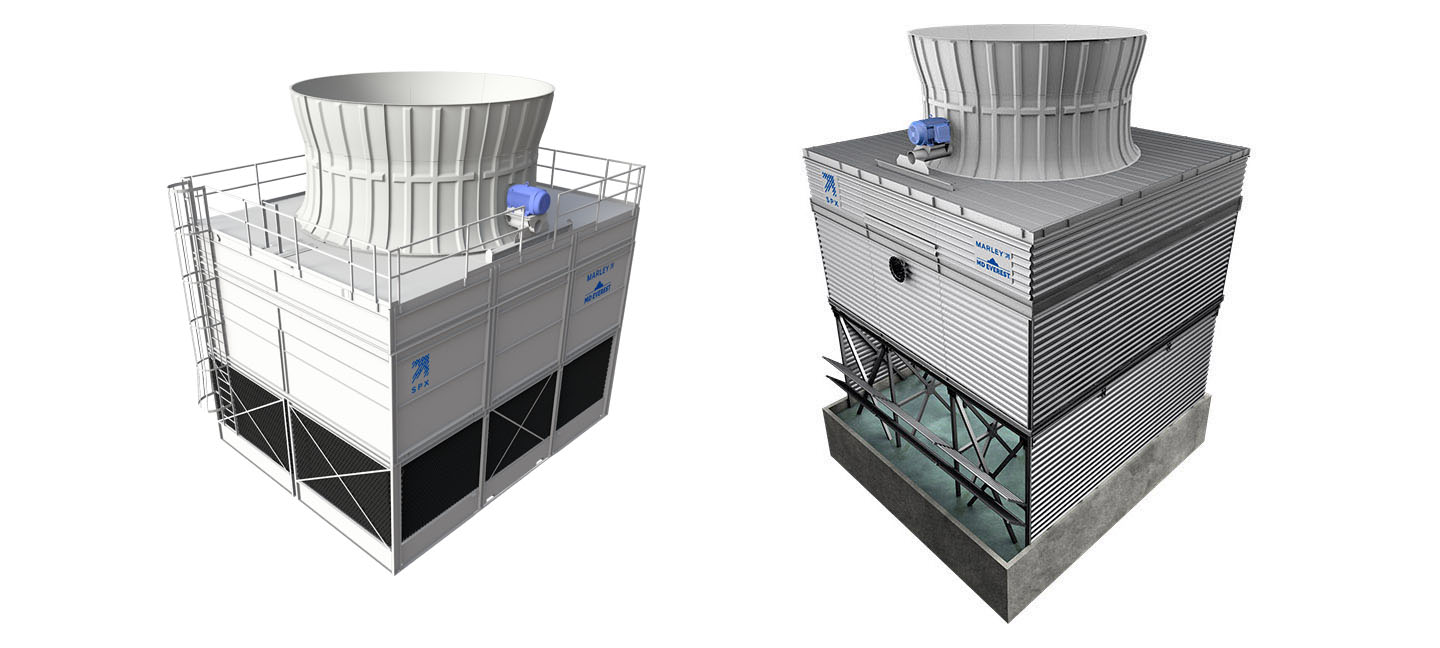

Counterflow Cooling Tower

TAKE COOLING TO A HIGHER ALTITUDE

When SPX Cooling Technologies engineers began their quest to design a new counterflow cooling tower, they were challenged to reach new heights in cooling performance. Also required was a tower design that would simplify and speed factory fabrication, delivery and field assembly.

The MD Everest Cooling Tower is uniquely suited for applications with higher cooling demands, including data centers, district energy complexes, health science campuses and industrial complexes. It incorporates robust materials of construction and industrial-grade components, proven to withstand the rigors of harsh environmental exposure. And its unique design comprises preassembled modules with fewer components, delivers to the job site up to 60% sooner and installs up to 80% faster than field-erected cooling towers.

Assembly

Brand: Marley

Configuration

Induced Draft

Availability: Worldwide

Capacity

Flow Rate: 1555 – 12602 gpm (1808-2862 m3/hr)

Thermal Capacity: 1227 – 3790 tons (5394-16676 kW)

Certifications

CTI Certified Thermal and Sound Performance

Eurovent Certified

FM Approved Options

OSHA Compliant

Details

HVAC and Process Cooling Applications:

Compared to other preassembled counterflow cooling towers, the MD Everest Cooling Tower offers monumental advantages for HVAC and Process Cooling applications:

- Up to 58% more cooling capacity than other preassembled cooling towers

- Cooling capacities from 1227-3790 tons offer one-to-one matches for large chillers

- Fewer piping and electrical connections reduce installation costs

- Low drift rates, down to 0.0005 percent of circulating water flow

Process Cooling Applications:

Compared to field-erected towers, the MD Everest Cooling Tower offers sky-high advantages for Process Cooling applications:

- Industrial-strength construction and materials to meet the rigors of process cooling applications

- Maximum flow rate up to 12,602 gpm/cell (2862m3/hr) to meet demands of process cooling

- Modular design for consistent quality and safer assembly processes and shorter work duration

- Broad range of heat transfer fill types to accommodate varying water quality

- Scalable design based on project requirements

CTI Certified Thermal and Sound Performance:

Offering exceptional thermal and sound performance, the MD Everest design is CTI Thermal and Sound certified, ensuring specified heat rejection and noise levels, with the long-term reliability expected from Marley. CTI Sound Certification provides independently verified sound data you can trust, helping reduce risk during design, simplify approvals, and ensure cooling equipment meets specified noise limits once installed.

ROBUST DESIGN AND MATERIALS

- Structural design and materials meets seismic and wind load requirements

- 5-year maintenance-free System 5 Marley Geareducer® gear drive

- Low fan energy requirement

- Spray system evenly distributes water over the fill

- Energy-efficient PVC heat exchange fill media options

- Motor outside the airstream standard

- Fill protected from sunlight to discourage algae growth

CERTIFIED THERMAL PERFORMANCE

Certified by the Cooling Technology Institute to meet thermal performance as specified.

Thank you for your recent purchase from SPX Cooling Technologies, Inc. We appreciate your business and look forward to serving you in the future.

Benefits of Registering Your SPX Product:

YOU’RE WARRANTED! Your product installation is verified and warranty is activated.

YOU’RE NOTIFIED! You receive immediate notification of important product information and service alerts.

YOU’RE INCLUDED! You receive invitations to exclusive educational programming and events, including School of Cool® tower maintenance workshops.

WE HEAR YOU! Your opinions about our products, services, technical support and programming are requested in voice-of-customer surveys.

SPX Cooling Technologies’ limited warranty terms will apply. For full details of your warranty coverage, please see the warranty certificate included with your product.

Complete the form below to register your product. Please make sure the information provided is accurate – all fields are required in order to register your product.