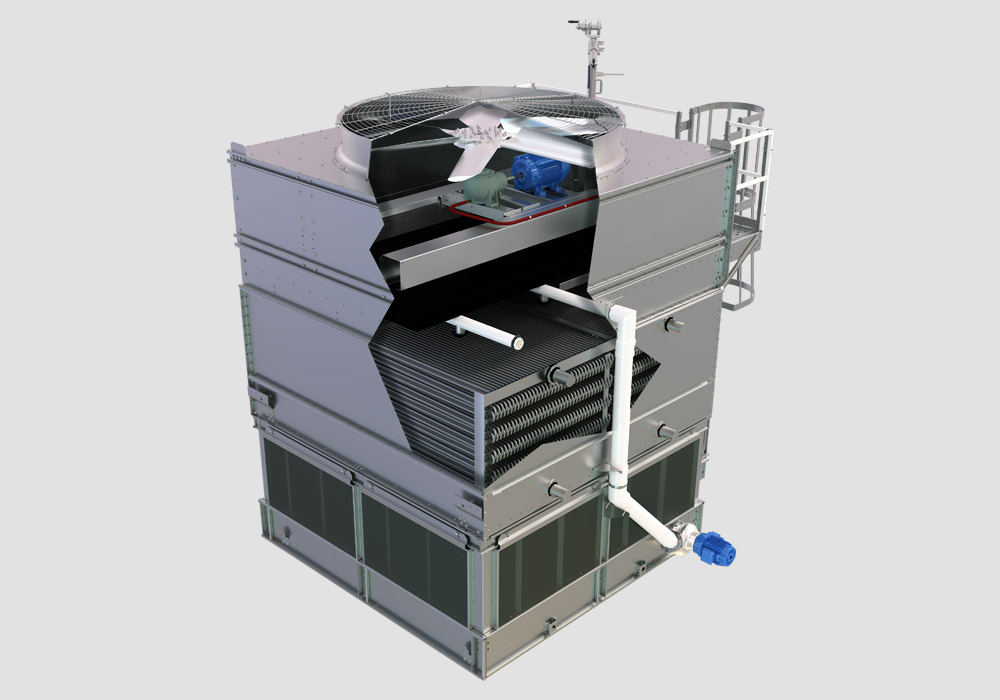

SGS DTC

Industrial Evaporative Condenser

Product Details:

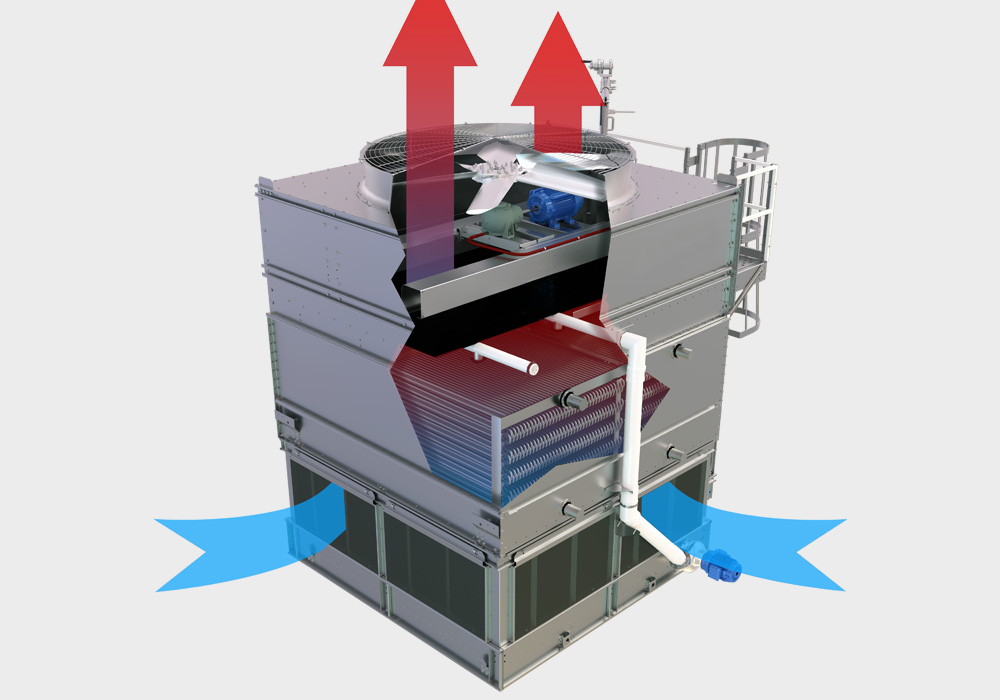

Induced Draft Counterflow Evaporative Condenser

Availability: North America

Thermal Capacity: 136 – 1272 R717 tons

Marley Geareducer® drive provides low maintenance, high reliability

Clog-resistant nozzles and triple-pass inlet louvers provide superior water management

Sound reduction options up to 15+dBA quieter than similar sized forced draft condensers

OSHA Compliant

Responsiveness

From specification review, product selection assistance and on-time delivery to installation coordination, commissioning and ongoing operational support, SPX customer service and sales teams provide an extra measure of attention, know-how and commitment to your satisfaction.

Value

SPX is committed to producing products with more value for our customers. The DTC Evaporative Condenser takes advantage of our team’s engineering and production strengths, as well as the business philosophy that meeting customer expectations is paramount to long-term success. Customers benefit from a well-engineered, robust and reliable product; and partnering with a business committed to customer satisfaction throughout the life of the product.

Worldwide Support and Quality

Our global network of sales and service specialists are ready to provide you the most responsive and knowledgeable product support. Rely on us for expert selection, installation and operational assistance. From tube production and bending, welding, parts fabrication and assembly, condenser components are produced, inspected, assembled and performance-tested to our high standards of quality.

Choose from a broad selection of induced draft models from 8.5’ to 12’ nominal widths and nominal lengths from 9’ to 36’ to meet your specific cooling and refrigeration requirements.

Built to Last

- Heavy duty galvanized steel structure and casing

- Submerged areas bolted or welded – not tap screwed

- Welded areas hot dip galvanized – not cold galvanized

- Stainless steel construction options

Easy to Install and Maintain

- Module connections designed for minimal fasteners

- Mechanical systems designed for reliability and service

- Self-draining, clog-resistant water distribution system

- Pre-assembled platform options with welded guardrails

- Large rectangular access doors

Features

- Marley Geareducer® drive standard for lowest maintenance and reliable performance with 5-year warranty; belt drive optional

- Triple-pass inlet louvers to control splash out and sunlight exposure to basin

- Dual U-bolt fan hub design to reduce de-pitching and vibration potential

- TEFC fan motors standard

- Sound reduction options enable induced draft selections with sound levels up to 15+ dBA lower than similar size forced draft condensers