Recold LC Evaporative Condenser

Evaporative Condenser

Product Details:

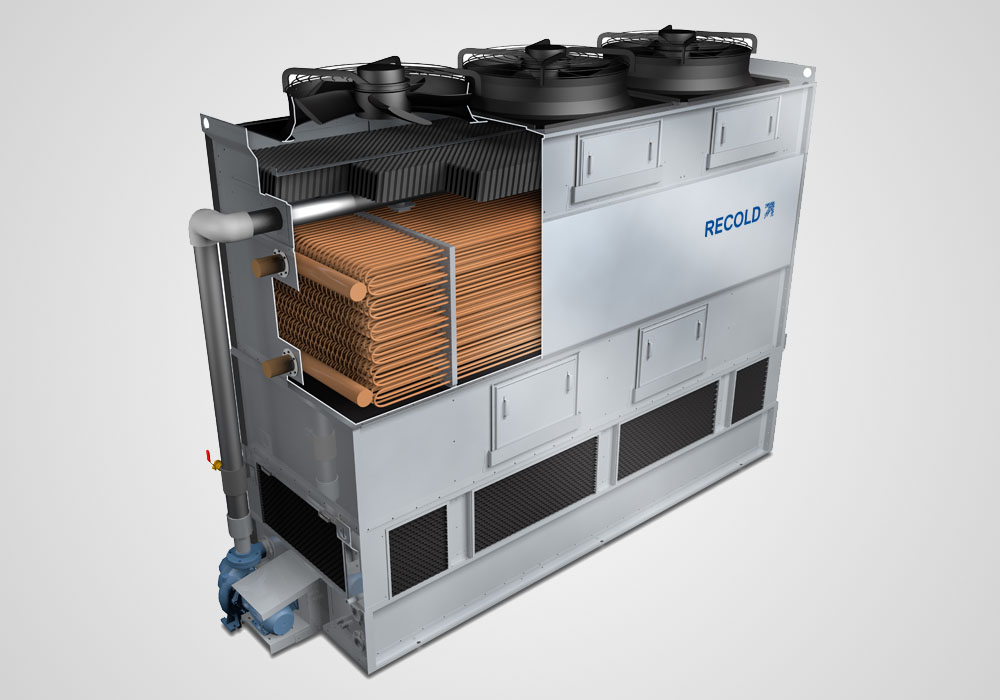

Induced Draft Counterflow Fill/Coil Hybrid Evap Condenser

Availability: North America

Thermal Capacity: 1200 – 5565 MBH

Direct drive fans standard

Single-piece installation, low height

Maintenance and access advantages

ASHRAE 90.1 Compliant

OSHA Compliant

The Recold LC Evaporative Condenser is an induced-draft counterflow evaporative condenser with patent-pending heat transfer technology. Its unique design reduces refrigerant charge up to 40 percent and lowers fan energy consumption by up to 50 percent compared to conventional evaporative condensers, while offering installation and maintenance advantages.

Applications

The Recold LC is well-suited for condensing halogenated refrigerants in supermarket refrigeration systems, small refrigerated warehouses and modular HVAC applications.

Installation Advantages

With standard unit heights less than 10.5 feet, the Recold LC Evaporative Condenser meets many municipal code height requirements and offers advantages for rooftop installations where low visibility is important. Other benefits include single-piece installation, single-point power connection, factory-installed controls, and factory wiring and testing.

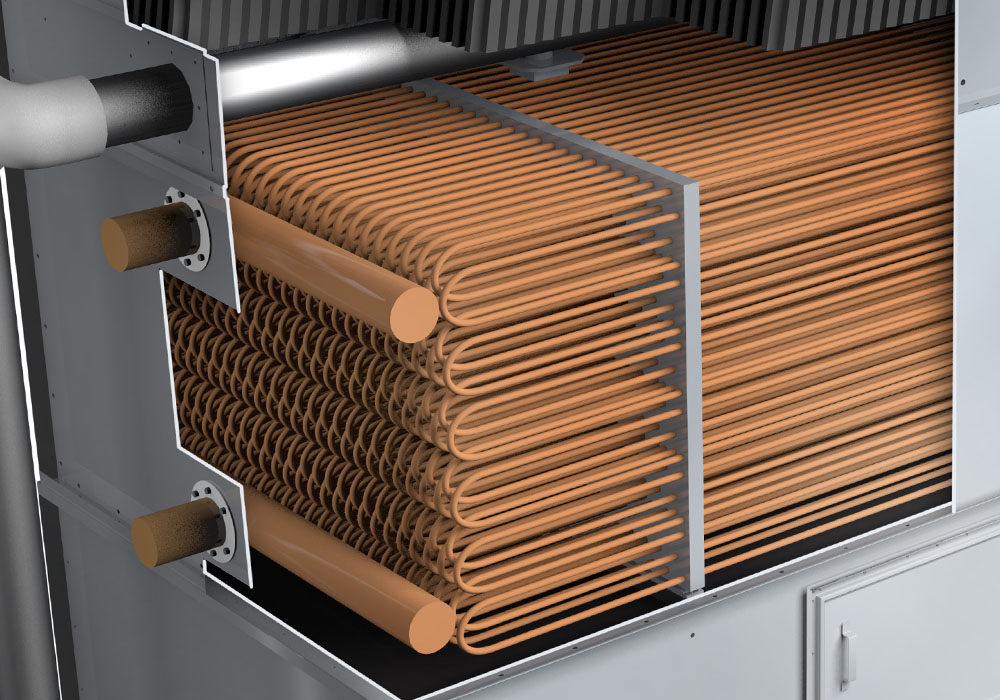

Copper Heat Exchange Coil

Copper heat transfer coils resist corrosion and offer greater thermal efficiency, which contribute to the LC Evaporative Condenser’s compact footprint and long service life. With 30-40 percent lighter weight than comparable galvanized steel coils, the copper coils are also bacteriostatic, recyclable, require less refrigerant charge, and are easily circuited to accommodate multiple rack systems.

Clog-Resistant Water Distribution System

Large 1-7/8” orifice spray nozzles help prevent debris build-up and clogging.

Direct Drive Fans

Direct drive fans eliminate the routine maintenance typically required for belt driven equipment, including periodic belt tensioning and bearing re-greasing. Fans are factory-wired to the unit control panel, which is factory-tested and shipped mounted on the unit for easy commissioning on site.

- ECM Direct Drive Fans

Standard fan drives incorporate high-efficiency electronically commutated motors (ECM) with integral speed control. ECM fan drives provide efficient operation at exceptionally low sound levels. - AC Motor Direct Drive Fans (LWA Models)

An optional drive system using NEMA premium efficiency fan motors is available, designed for use with external variable speed drives (VFDs). Models with AC motors (LCA models) deliver the same unit performance as models with ECM drives, with slightly higher sound levels as a tradeoff for improved availability in a world of electronics supply vulnerabilities.

Multiple Access Doors

Six to 10 gasketless doors per cell can conveniently be removed for access to interior components, such as the spray, coil and fill compartments.

Robust Construction

As a standard, the LC Evaporative Condenser includes a bolted stainless steel collection basin. All collection basin and air inlet parts exposed to circulating water, including coil supports, attaching hardware and optional basin components, are heavy-gauge series 300 stainless steel. Heavy-mill galvanized steel comprises the balance of the tower structure and mechanical supports.

PVC Air Inlet Louvers

PVC air inlet louvers restrict splashout and offer easy access to the collection basin from all sides.

PVC Drift Eliminators

High-efficiency, triple-pass PVC eliminators limit drift and are removable for inspection.

2. Recirculating water is pumped from the collection basin to the pressurized distribution system and is distributed over the coils.

3. Recirculating water flows over the outside of the coil tubes, removes heat from the refrigerant, and flows onto the fill media below the coil.

4. Air induced through the condenser evaporates a small portion of the recirculating water, rejecting heat to the atmosphere.