Factory-Assembled Closed Circuit Fluid Coolers

for machine cooling and lower heat loadsCOOLING TOWER APPLICATIONS / INDUSTRIAL PROCESS COOLING

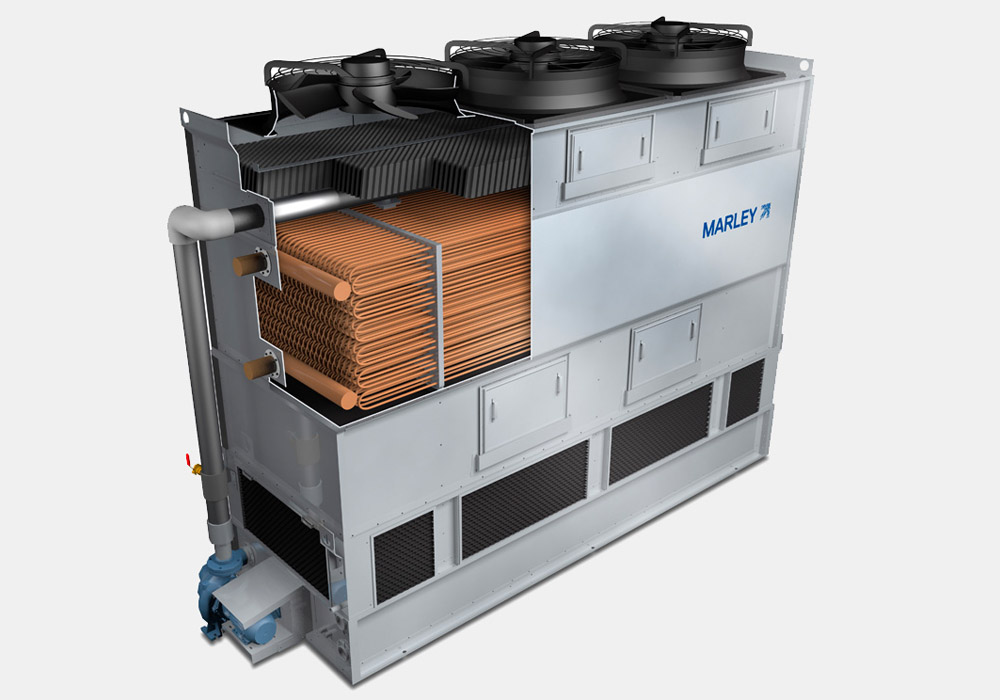

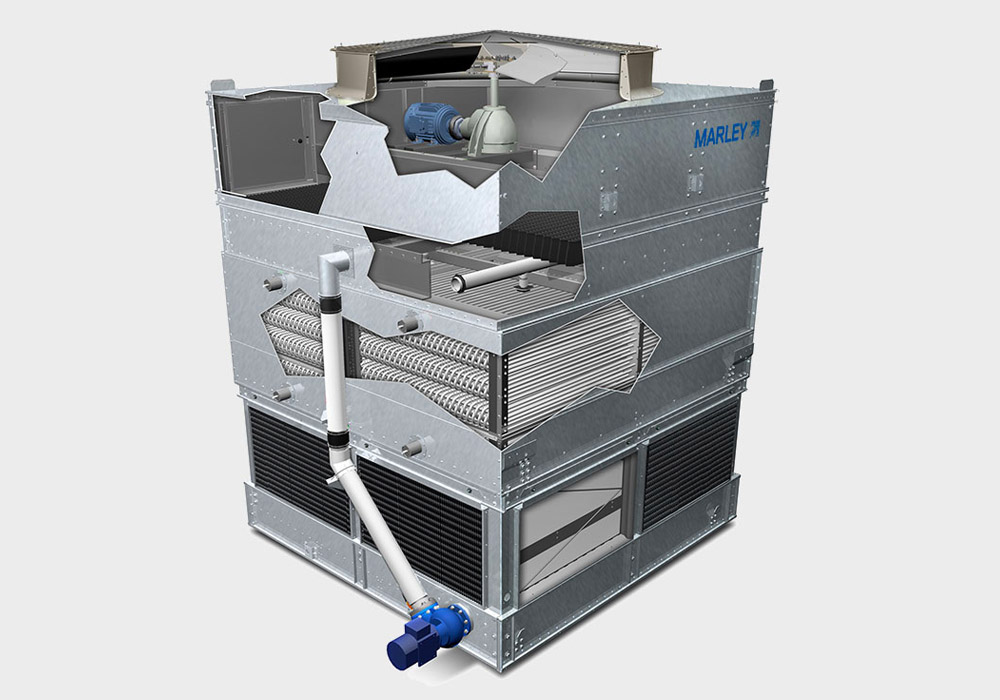

Some Marley hybrid-design Fluid Coolers incorporate heat transfer media to drive greater cooling efficiency while conserving fan power and space. Others, without heat transfer media, offer greater dry operation flexibility in cold weather.

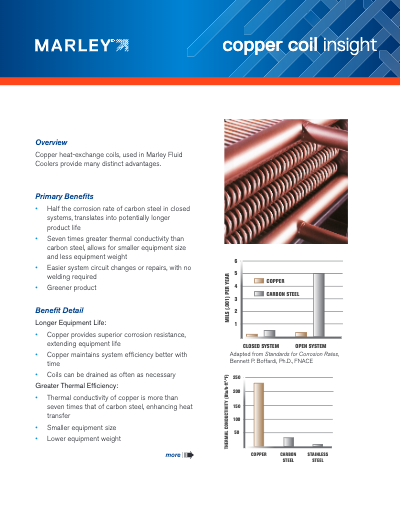

Copper Coil option. Compared to traditional hot-dip galvanized (HDG) coils, copper provides superior corrosion resistance and 15-30% more thermal capacity. Copper coils are lighter, use 35% less fluid volume and require 35% less fan power.

5-year mechanical warranty to help keep your industrial processes running smoothly year after year.

Certified performance by the Cooling Technology Institute (CTI) with water, ethylene glycol solutions and propylene glycol solutions.

Low-sound fans as standard and multiple fan and attenuation options to meet more stringent requirements.

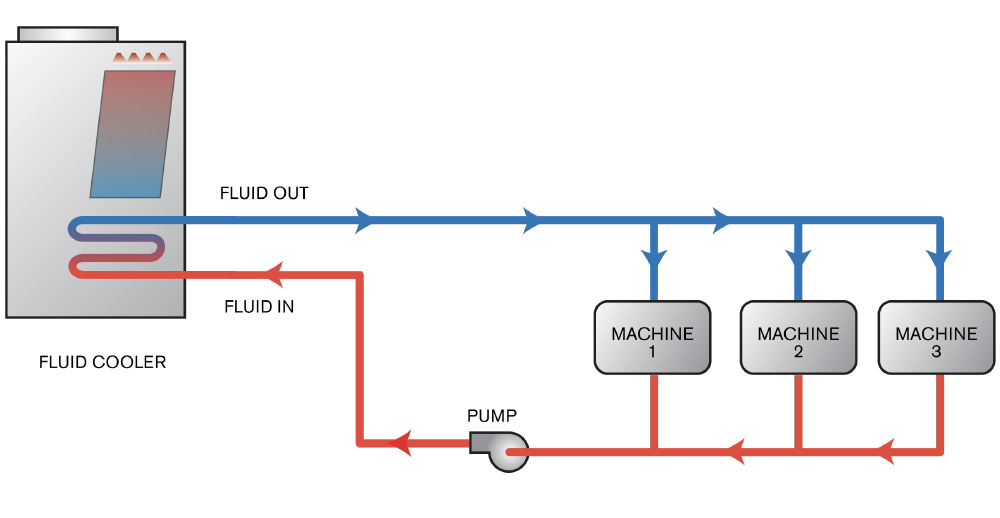

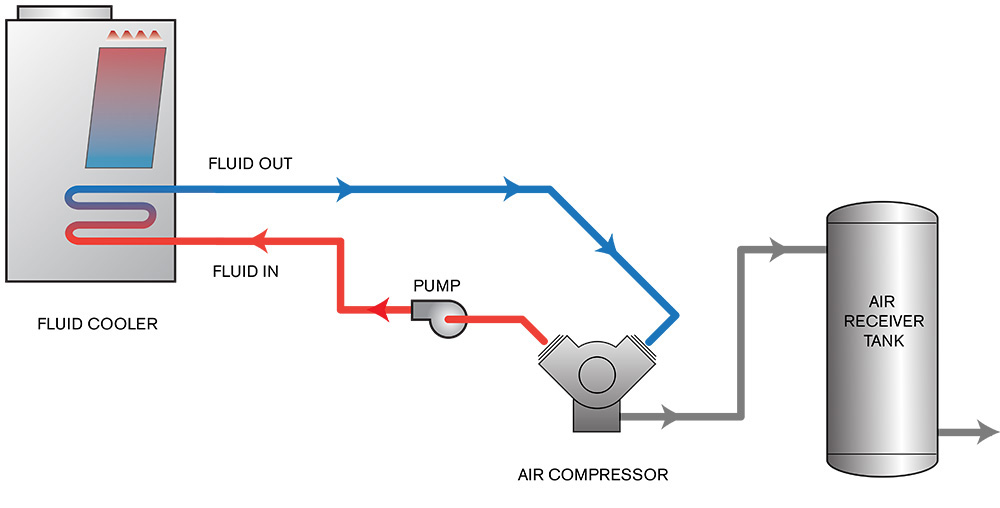

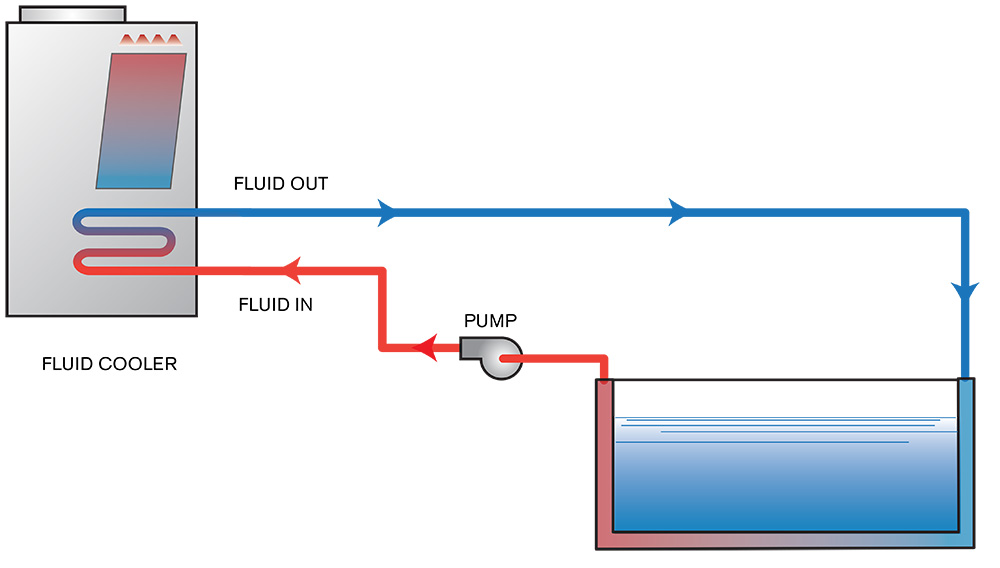

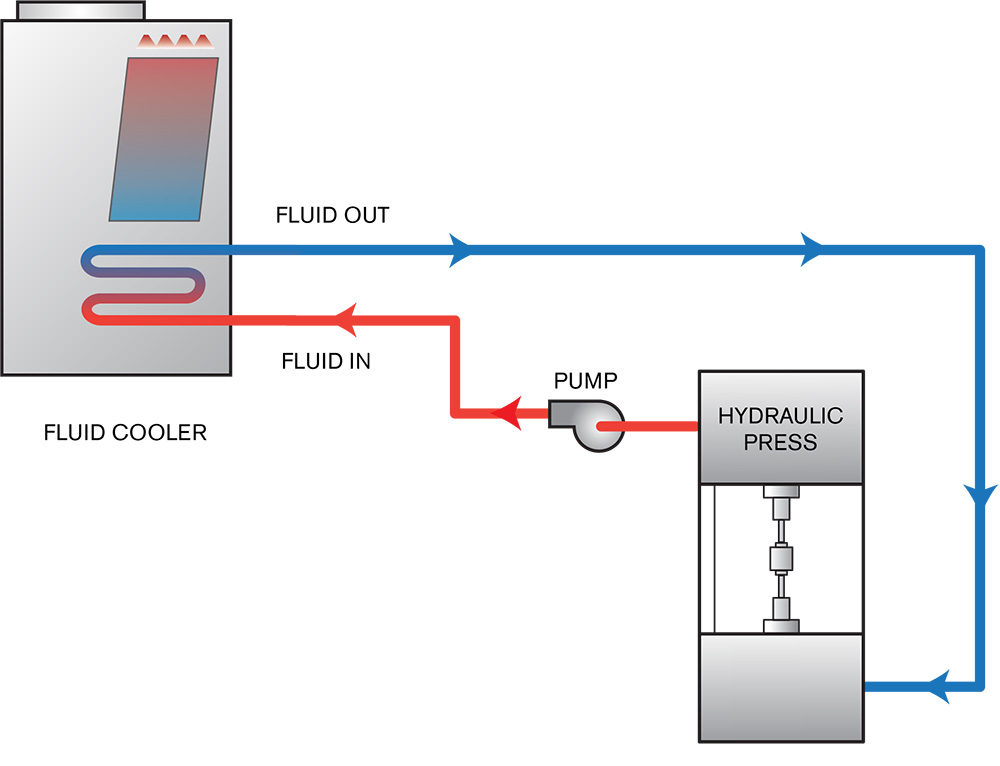

Fluid Cooler Applications:

Machine Cooling

Learn more about how Marley Closed Circuit Cooling Towers can be part of your industrial process cooling solution:

Advance your evaporative cooling knowledge through recorded webinars presented by SPX Marley technical experts. Register now and watch any time.

Copper heat-exchange coils, used in Marley Fluid Coolers provide many distinct advantages. Learn more about the benefits of copper here.

Use this form and an SPX team member will reach out today.

To speak with someone immediately, call 1-800-4-Marley.