OLYMPUSMAX™

The Peak of Fluid Cooler Performance

Why OlympusMAX?

Flexible Design Options

Offered as both dry and adiabatic fluid cooler configurations, with post-installation, bolt-on adiabatic kit option available.

Simplified Installation

Controls are factory assembled with electrical station access platform fully assembled and a single-point wiring connection to the unit.

Improved Efficiency

Unique recirculating water system minimizes water use, improves adiabatic efficiency, limits scaling and helps extend pad life.

Optimized Energy Usage

User-friendly control system included to regulate water/energy usage, with option to convert dry units to adiabatic in the field.

Built for Uptime

Quality materials, robust construction methods and proven mechanical equipment designed for lasting performance and reduced downtime.

High Density

Designed to maximize dry cooling capacity for available footprint.

Flexible Efficiency. Trusted Performance.

Mission-Critical Design

- Extended heat rejection capabilities over 131F (55C)

- High-density design maximizes usable space–available in 120, 160, 200 and 240hp versions

- Safer, easier access to all potential failure points, including interior mechanicals and control panels

- Unique upgrade option allows your facility to expand units from dry to adiabatic with in-field conversion package

- Integrated redundancy on mission-critical components like fans and VFDs

|

Design Element |

Detail |

|

Unit Sizes |

Double Stacked, Modular 4 Fan |

|

Air Flow Type |

Induced Draft, Vertical Discharge |

|

Fans |

High-efficiency Low Sound or Ultra Quiet Gear-driven |

|

Drive System |

Marley Geareducer® gear drive |

|

Motors |

Premium Efficiency TEFC |

|

Coil Construction |

Stainless steel or copper tube and aluminum or coated aluminum fin |

|

Unit Construction |

Galvanized steel with stainless steel wet areas; all stainless steel option |

|

Adiabatic Design |

Pad/Media – Recirculating (adiabatic units only) |

|

Water System |

Integral Recirculating Pump (adiabatic units only) |

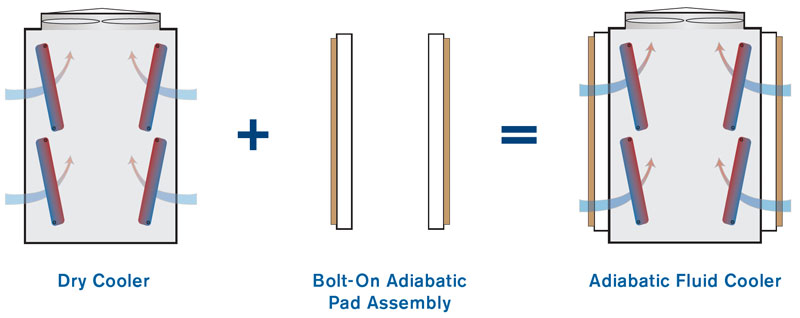

Bolt-On Flexibility

The innovative construction of the Marley OlympusMAX allows for the recirculating adiabatic pre-cooling system to be installed in the field, providing more flexibility on cooling capacity. This option allows for applications initially specified as dry to be converted to adiabatic later by using an easy-to-install bolt-on kit as cooling demand increases.

Optimized Adiabatic Design

The OlympusMAX recirculating design collects and reuses water in the adiabatic system, decoupling water distribution from water usage. The design allows users to dial in water capacity by cell to further optimize usage.

Efficient Water Delivery

Higher flow rates typically associated with recirculation systems help limit dry spots and ensure uniform wetting of the pad, maximizing efficiency and lengthening pad life. Recirculating systems also limit total water usage; once-through or spray systems typically run lower flow rates or risk excessive water use.

Unique Recirculation System Design

Traditional designs pull from a mixture of blowdown and makeup water, but Marley’s adiabatic design segregates the two streams to minimize wasteful discharge of cleaner water and ensure the most concentrated stream is rejected.

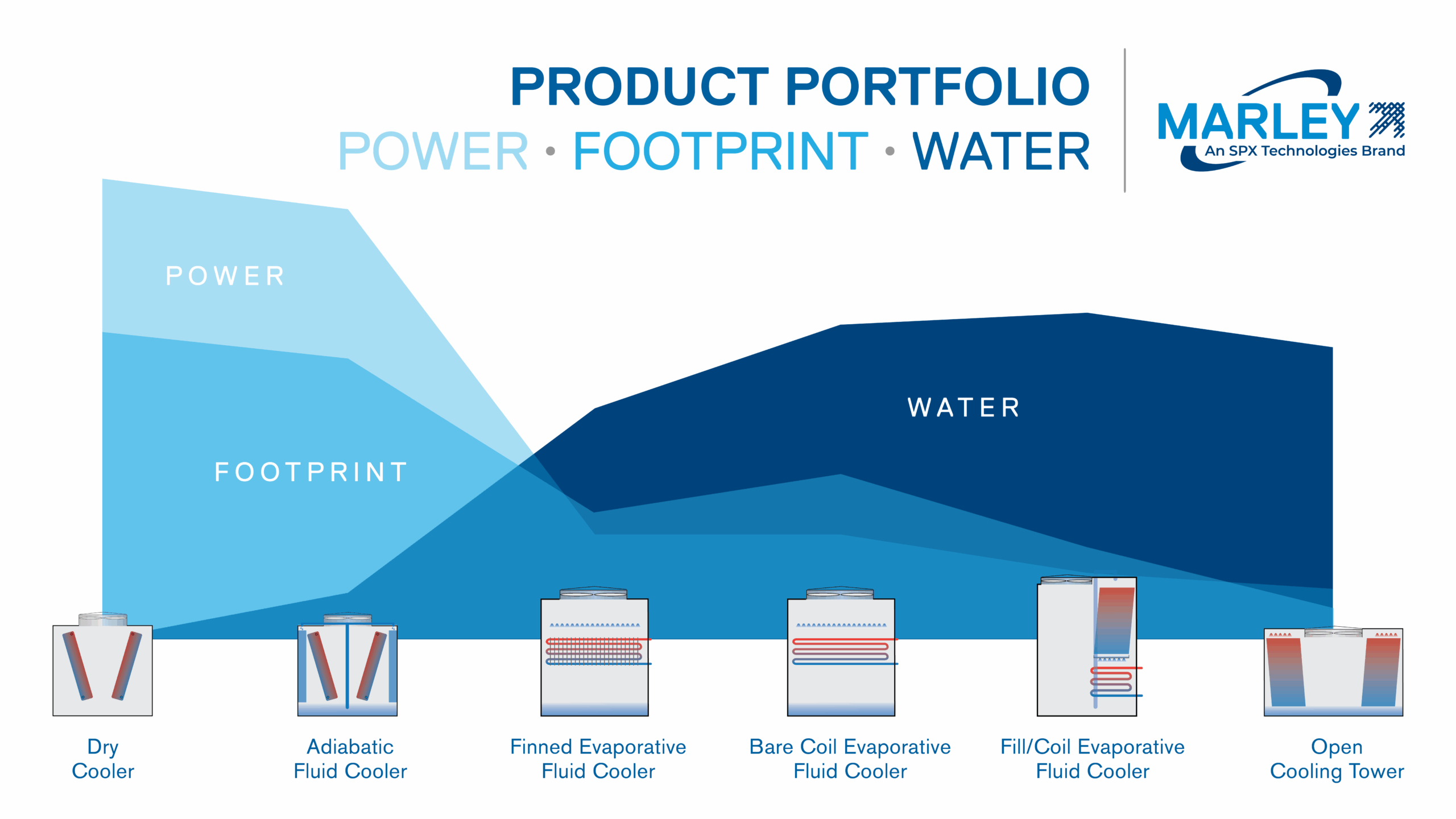

A Full Range of Product Solutions

With a range of scalable, modular options, and a 100+ year history of reliable performance, Marley cooling solutions are an excellent fit for mission-critical applications. Marley offers a complete portfolio of heat rejection equipment to meet your needs:

- Cooling Towers

- Evaporative Fluid Coolers

- Adiabatic Fluid Coolers

- Dry Coolers