What Is Evaporative Cooling?

The Oxford English Dictionary defines Evaporative Cooling as the “Reduction in temperature resulting from the evaporation of a liquid, which removes latent heat from the surface from which evaporation takes place. This process is employed in industrial and domestic cooling systems, and is also the physical basis of sweating.”

Beyond sweating, evaporative cooling is the process responsible for the cooling effect experienced after having a swim or hot shower. Evaporative cooling towers harness the natural power of evaporative cooling to reduce the temperature of water used in industrial processes and in commercial HVAC comfort cooling systems.

What Is an Evaporative Cooling Tower?

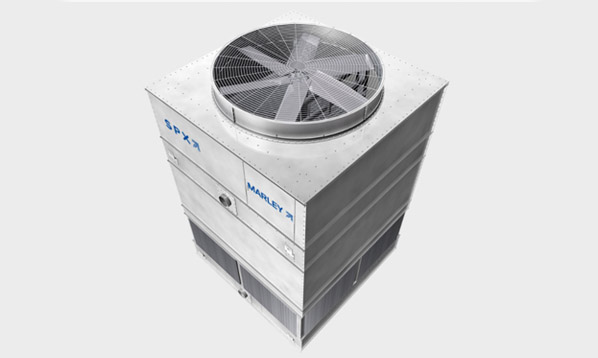

A cooling tower is a specialized heat exchanger in which air and water are brought into direct contact with each other in order to reduce the water’s temperature. As this occurs, a small volume of water is evaporated, reducing the temperature of the water being circulated through the tower.

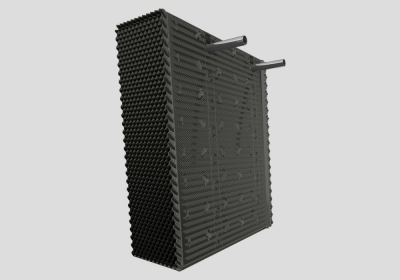

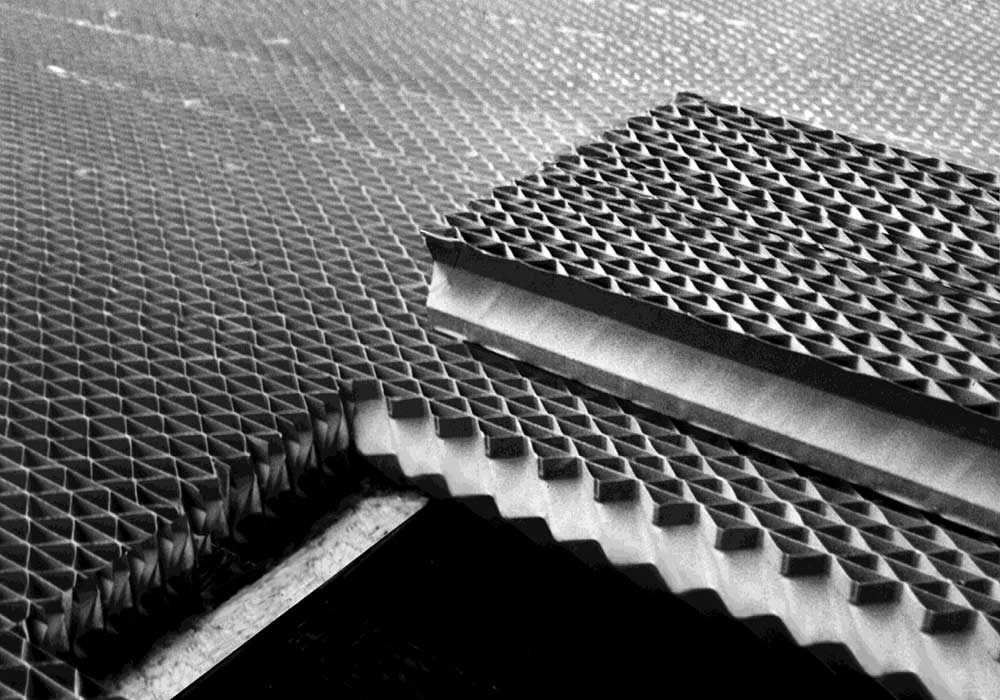

Water, which has been heated by an industrial process or in an HVAC system condenser, is pumped to the cooling tower through pipes. Water entering the cooling tower is sprayed through nozzles onto layers of heat transfer media called “fill,” which slows the flow of water through the cooling tower, and creates greater surface area for the water to spread for maximum air-water contact. As the water flows through the cooling tower, it is exposed to air being pulled through the tower by a motor-driven fan.

When the water and air meet, a small amount of water is evaporated, creating evaporative cooling action. The cooled water is then pumped back to the HVAC condenser or industrial process equipment where it again absorbs heat and then back to the cooling tower in a continuous cycle.

Resources:

On Demand Webinar

Cooling Tower Fundamentals presents basic evaporative cooling and cooling tower principles in video format for those wanting to learn more.

Cooling Tower Fundamentals Handbook

Cooling Tower Fundamentals Handbook is a valuable resource that includes a glossary of terms, review of cooling tower design types and operation, components, and owner responsibilities.

Not all cooling towers are suitable for all applications. Evaporative cooling towers are designed and manufactured in several type and size categories. Understanding the various types, along with their advantages and limitations, is important when determining the best evaporative cooling solution to meet project requirements.

Crossflow Cooling Towers

In crossflow cooling towers the water flows vertically through the heat transfer fill while the air flows horizontally, across the flow of the falling water. Because of this, air does not have to pass through the water distribution system.

Consequently, gravity flow hot water basins are mounted at the top of the cooling tower above the fill media.

Counterflow Cooling Towers

Counterflow cooling towers are designed so that air flows vertically upward, counter to the flow of falling water in the heat transfer fill. Because of this vertical airflow, counterflow cooling towers use pressurized pipe and nozzle systems to spray water onto the heat transfer fill.

Since air must pass through the spray system, the pipes and nozzles are spaced to allow adequate airflow.

Crossflow vs. Counterflow Cooling Towers

Learn more about the difference with this video from SPX Cooling Technologies, Inc.

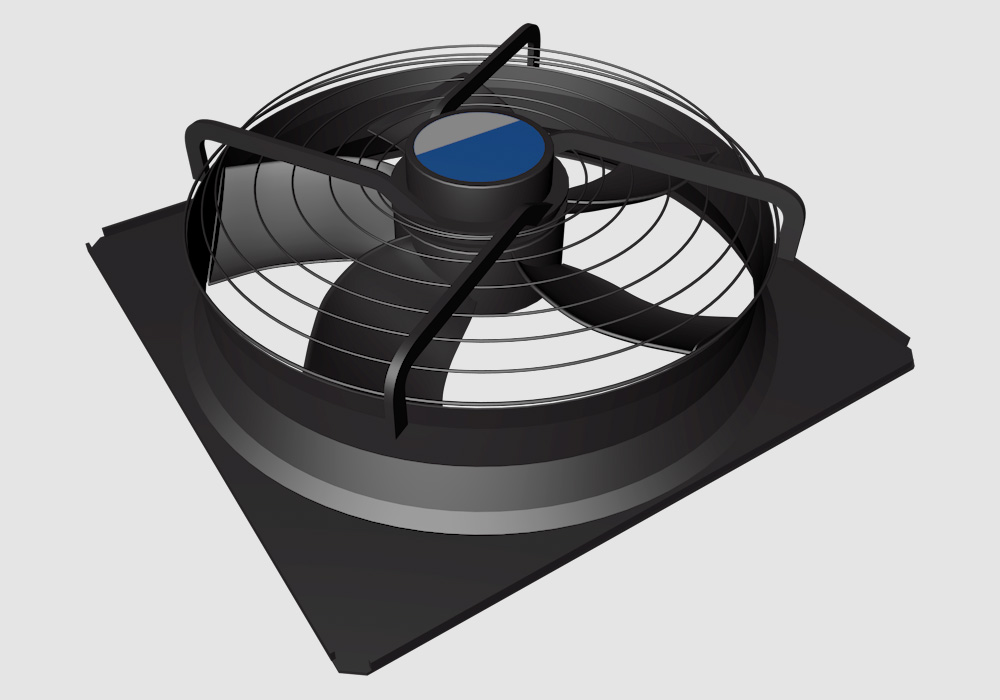

Induced-draft cooling towers have fans that are typically mounted on top of the cooling tower to pull air through the fill media. Conversely, forced draft cooling towers employ blowers located at the base of the air inlet face to push air through the cooling tower.

Factory Assembled (FAP) vs. Field Erected (FEP) Evaporative Cooling Towers

Factory-assembled evaporative cooling towers (FAP) are built in as few sections as the mode of transportation will permit. A small cooling tower can often ship essentially intact. A larger, multi-cell cooling tower is manufactured in modules at the factory, and shipped ready for final assembly. Factory-assembled cooling towers are also referred to as “package” or “FAP” (factory-assembled product).

Factory-assembled cooling towers can be crossflow or counterflow design, induced draft or forced draft, depending on the application. Examples include the Marley NC® crossflow, induced-draft cooling tower and Marley MD counterflow, induced-draft cooling tower. Both are widely used for HVAC and light industrial process applications.

Field-erected evaporative cooling towers are primarily constructed at the site of ultimate use. All large cooling towers, and many smaller, modular towers, are prefabricated, piece-marked, and shipped to the job site for final assembly. The manufacturer typically provides assembly labor and supervision. Field-erected cooling towers can be crossflow or counterflow design. Examples include the Marley F400 counterflow cooling tower and Marley F600 crossflow cooling tower. Both are employed for power generation and heavy industrial process applications and customized to meet performance, structure, drift, and plume abatement specifications.

Marley® Evaporative Cooling Tower Performance Drivers

Using a total system approach, Marley cooling towers and their components are engineered and built to work together as parts of an integrated system to provide the cooling tower operator with reliable performance, including energy and water efficiency, dependable operation, and long service life.

Energy & Water Efficiency

HVAC Free Cooling – The goal of a free cooling system is to save energy. A free cooling system saves energy costs by allowing the cooling tower to directly satisfy a building’s cooling needs without operating the chiller in cold weather. The amount of potential energy savings available depends almost totally on the overall system design and on the selection of equipment for use in the system. In general, the designer and owner must balance higher equipment first cost with greater opportunity for energy savings. Learn more about Free Cooling.

Variable Flow – Variable flow is a way to maximize the effectiveness of the installed tower capacity during off-peak conditions. Potentially 75% of the fan energy can be saved, if proper water distribution can be achieved within the cooling towers. Learn more about Variable Flow.

Dependable Operation and Long Service Life

Marley Geareducer® Gear Drives – SPX engineers designed Marley Geareducer drives specifically for reliable, long lasting, evaporative cooling tower duty with a five-year warranty and 5-year oil change interval. They are available in a range of designs and reduction ratios to accommodate cooling tower fan speed and horsepower requirements. Learn more about Geareducer Drives.

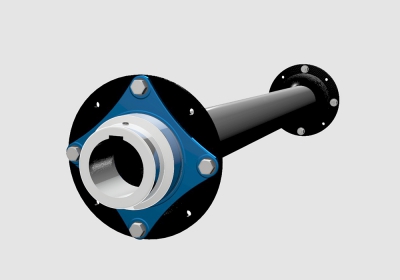

Couplings and Driveshafts – Couplings and driveshafts must be strong and durable to efficiently transmit power from the motor to the Marley Geareducer gear drive. Marley Couplings and Driveshafts are specifically designed for cooling tower duty and highly corrosion-resistant. Learn more about Couplings and Driveshafts.

Contact your Marley Sales Representative for expert advice and product selection assistance.