Air-Cooled Heat Exchangers

Home / Library / Air-Cooled Heat Exchangers

Air-Cooled Heat Exchangers

Brochures

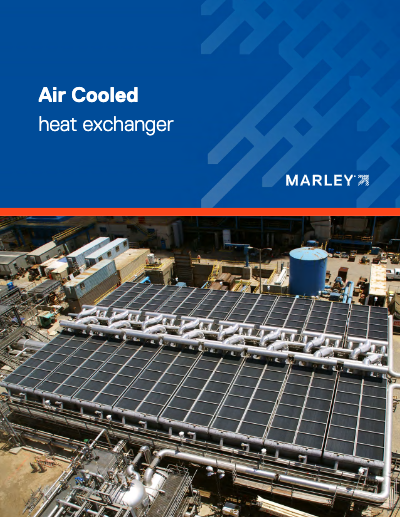

Marley Air Cooled Heat Exchangers stand up to the demanding requirements for heat transfer processes in chemical, oil and gas, process and power generation applications.Available Document Languages