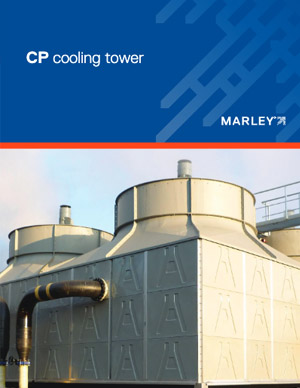

Marley CP

Counterflow Cooling Tower

Product Details:

Availability: Europe and the Middle East

Flow Rate: 774-4011 gpm (176-911 m3/hr)

Thermal Capacity: 258-1337 tons (1134-5878 kW)

CTI Certified Thermal and Sound Performance

Eurovent Certified

Designed in accordance to Eurocode 3 for steel structures (DIN EN 1993).

Factory-assembled without field welding

Also available in preassembled modules or knock down

Completed tower hoisted after assembly

The Marley CP Cooling Tower is an induced-draft, counterflow tower uniquely designed for space- and sound-sensitive applications. It features a stainless steel internal structure and fiberglass reinforced polyester (FRP) casing to resist corrosion and chemical attack.

A range of heat transfer fill media accommodates clean-to-very dirty water applications. The Marley CP Cooling Tower can be fully factory assembled, partially assembled, or shipped fully knock-down for on-site assembly.

CTI and Eurovent Certified

The thermal performance of the Marley CP Cooling Tower is tested and certified by the Cooling Technology Institute (CTI) and Eurovent. Additionally, all published sound data for Marley CP Towers is CTI Certified so you can trust that your cooling tower will meet sound levels as specified.

Mode of Operation

Hot water flows into the cooling tower through PVC (polyvinyl chloride) or polypropylene piping to the water distribution system. Spray nozzles uniformly distribute fine droplets of hot water from above the heat transfer fill. The cooling air is provided by an induced-draft axial fan. Air absorbs the heat from the water by evaporation and convection.

Heat Transfer Fill Media

Clean water applications utilize PVC or polypropylene film fill packs. Dirty water containing higher suspended solids content requires clog-resistant or splash fill.

Mechanical Equipment

The fan is mounted directly on the geared motor shaft. Fan blade pitch is adjustable to process conditions. The low-noise cooling tower duty motor is engineered to withstand high heat and moisture conditions and suitable for continuous operation with a variable frequency drive (VFD). Motor and fan are mounted on a hot dip galvanized (HDG) steel (or optional stainless steel) support structure.

Multiple Cells Configuration

Multi-cell CP Cooling Towers can be installed inline or back-to-back.

Electric basin heater: Immersion heater helps prevent freezing during cold weather.

Electric oil level switch: Monitors geared motor oil supply.

External lube line: Facilitates oil changes.

Maintenance platform: Stable HDG steel work surface provides safe access to mechanical equipment.

Vibration switch: Automatically shuts down motor to help protect against mechanical failure due to high vibration level.

Ultra quiet fan: Maximizes efficiency while reducing sound levels.

Thank you for your recent purchase from SPX Cooling Technologies, Inc. We appreciate your business and look forward to serving you in the future.

Benefits of Registering Your SPX Product:

YOU’RE WARRANTED! Your product installation is verified and warranty is activated.

YOU’RE NOTIFIED! You receive immediate notification of important product information and service alerts.

YOU’RE INCLUDED! You receive invitations to exclusive educational programming and events, including School of Cool® tower maintenance workshops.

WE HEAR YOU! Your opinions about our products, services, technical support and programming are requested in voice-of-customer surveys.

SPX Cooling Technologies’ limited warranty terms will apply. For full details of your warranty coverage, please see the warranty certificate included with your product.

Complete the form below to register your product. Please make sure the information provided is accurate – all fields are required in order to register your product.