If you’ve noticed a drop in performance, have been experiencing continuous issues or making frequent repairs to your fluid cooler, it may be time to replace your unit. But, with so many options available now, choosing the right fluid cooler for your heat rejection needs is no easy task. Regardless of what you’re cooling in your closed-circuit cooling unit, here’s a rundown of the different options available and what each type offers for your system.

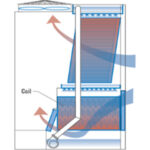

Fill / Coil Hybrid Fluid Coolers

As the name implies, this type of fluid cooler uses open cooling tower fill media in combination with heat transfer coils for closed loop cooling. The addition of fill media boosts the heat transfer efficiency versus traditional fluid coolers with coils only. Fill/coil hybrid Fluid coolers offer several benefits, including:

- Highest capacity per footprint

- Lowest fan energy usage

- Lowest first cost

- Coil material choices of copper, galvanized or stainless steel

Induced Draft Counterflow Fluid Coolers

This popular fluid cooler type has only bare tube serpentine coils that serve as the heat exchange surface. Depending on the process load, fluid cooler model and water cost in the area, this fluid cooler type can sometimes provide operational savings annually, and its higher dry switch point can help to greatly limit water usage. Overall, its main characteristics include:

- Dry operation flexibility

- Possible annual operating savings

- Higher first cost

Induced Draft Counterflow Finned Fluid Cooler

This fluid cooler is also an induced draft counterflow “coil only” design, but extended surface fins are added to the heat transfer coils. These finned coils provide higher dry capacity and a lower footprint than its bare tube counterparts, but usually come with a higher cost upfront. If considering an induced draft counterflow finned fluid cooler, remember they come with:

- Higher dry capacity

- Smaller footprint (than counterflow bare tube)

- Higher first cost

Forced Draft Counterflow Fluid Cooler

This older technology is becoming less popular because of its high fan energy usage, but is still common in the field right now. Many of these fluid coolers are being replaced with induced draft products, unless it’s being used in an indoor ducted system where a forced draft is necessary. The main considerations for these models are:

- High external static capability (indoor/ducted applications)

- Uses approx. 2X fan energy of induced draft

- Outdoor installations usually replaced with induced draft

Low Profile Forced Draft Fluid Cooler

Like other forced draft fluid coolers, these units use a centrifugal fan to force the air through the coil. But these units typically have the blower on the side to reduce the height of the cooler. Characteristics include:

- High external static capability (indoor/ducted applications)

- Ideal for low height installations

- Uses approx. 2X fan energy of induced draft

Making Your Choice

In the end, the right fluid cooler has a lot to do with exactly what your building needs. If you’re focused on energy efficiency, a fill/coil hybrid product may be your best choice; if you want to operate dry seasonally and don’t mind the higher initial cost, then an induced draft counterflow might be your best bet. For assistance with choosing the right fluid cooler, you can input your system’s requirements into CoolSpec® product selector, a tool designed to help you get the most out of your evaporative cooling system.

To get help from a technical representative in your area, click below and we’ll reach out for more specific information about your needs. Get Help Choosing Your Fluid Cooler: