Green Evaporative Cooling Brochure

Green builders looking for an environmentally responsible cooling system and exceptional performance need look no further. SPX Cooling Technologies, a U.S. Green Building Council member and LEED® advocate, offers you the perfect solution—Evaporative Cooling.

Recold JT Series Cooling Tower

The JT Cooling Tower is a ruggedly built unit constructed to provide many years of durable, dependable service with minimal maintenance requirements. Quality materials and workmanship are a key factor in meeting this objective.

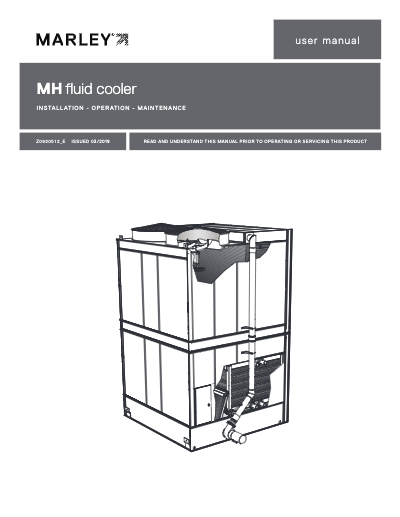

MH Fluid Cooler User Manual

- Installation, operation and maintenance instructions as well as those offered separately on motors, fans, float valves, etc.- are intended to assure that your MH Fluid Cooler serves you properly for the maximum possible time.

MarleyGard Low-Flow Nozzle Cups

Simple modifications to Marley crossflow cooling towers permit variance in the flow rate over a wide range by varying the number of nozzles that are active as a function of the flow rate. Installing low-flow nozzle cups can effectively divide the hot water distribution basin into outboard and an inboard sections.

Recold J Series Fluid Cooler, Evap Condenser and Cooling Tower

The Recold J Series has proven itself in application after application, including HVAC, refrigeration, and a wide array of industrial processes such as plastics, heat-treating, and air compressor cooling. What's more, we frequently add value by configuring systems for special requirements.

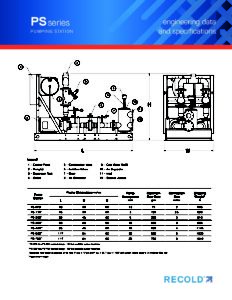

Recold Pumping Station

Recold PS Series Pumping Station engineering data for Recold Cooling Towers, Evap Condensers and Fluid Coolers.

Marley MC Fluid Cooler

The Marley MC steel forced draft counterflow fluid cooler is the ideal solution for sound- and space-sensitive applications.

Recold JC Series Evap Condenser Engineering Data

The JC Evaporative Condenser is a ruggedly built unit constructed to provide many years of durable, dependable service with minimal maintenance requirements. Quality materials and workmanship are a key factor in meeting this objective.