CoolBoost Opti FC Control Panel for Marley MH and DT Fluid Coolers

Flexible Operating Modes Optimize System Performance: Broad range of operating modes are available with the software, Optimize between energy and water savings, Select Dry Priority – no pump or fan first options, Select Wet Priority – no fan or pump first options.

Sound Power Impacts per CTI Code Revision

The most common code for measuring and reporting cooling tower sound in North America is Cooling Technology Institute (CTI) ATC-128, Test Code for Measurement of Sound from Water-Cooling Towers.

Basin Heater Steam Injection

Penberthy NWH bronze steam jet heaters are available for freeze protection (installation by others) in cooling tower cold water basins.

Fluid Cooler Cold Weather Operation

Preparing a fluid cooler for cold weather operation or shutdown season is similar to an open cooling tower, but with additional requirements. This paper discusses special considerations needed for cold weather operation and freeze protection for fluid coolers.

Pump Flow vs. Gravity Flow

Is the cooling tower operating on pump flow or gravity flow? This question is often misunderstood and sometimes results in hydraulic or scope issues that could have been easily avoided.

Use of Vibration Isolators

Vibration isolators are used with cooling towers as a method to reduce the transmission of vibration, produced by rotating mechanical equipment or water flow, into or within a building structure.

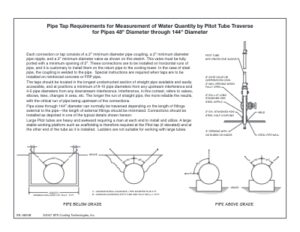

Pipe Tap Requirements (48” — 144” diameter)

The taps should be located in the longest unobstructed section of straight pipe available and easily accessible, and at positions a minimum of 8-10 pipe diameters from any upstream interference and 4-5 pipe diameters from any downstream interference.

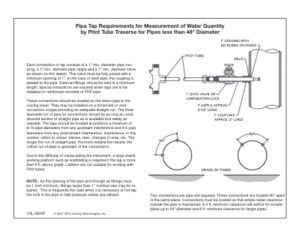

Pipe Tap Requirements (up to 48” diameter)

These connections should be located on the return pipe to the cooling tower. They may be installed on a horizontal or vertical section of pipe providing an adequate straight run.