XCEL TU Drift Eliminator

Cooling Tower Parts

Overview

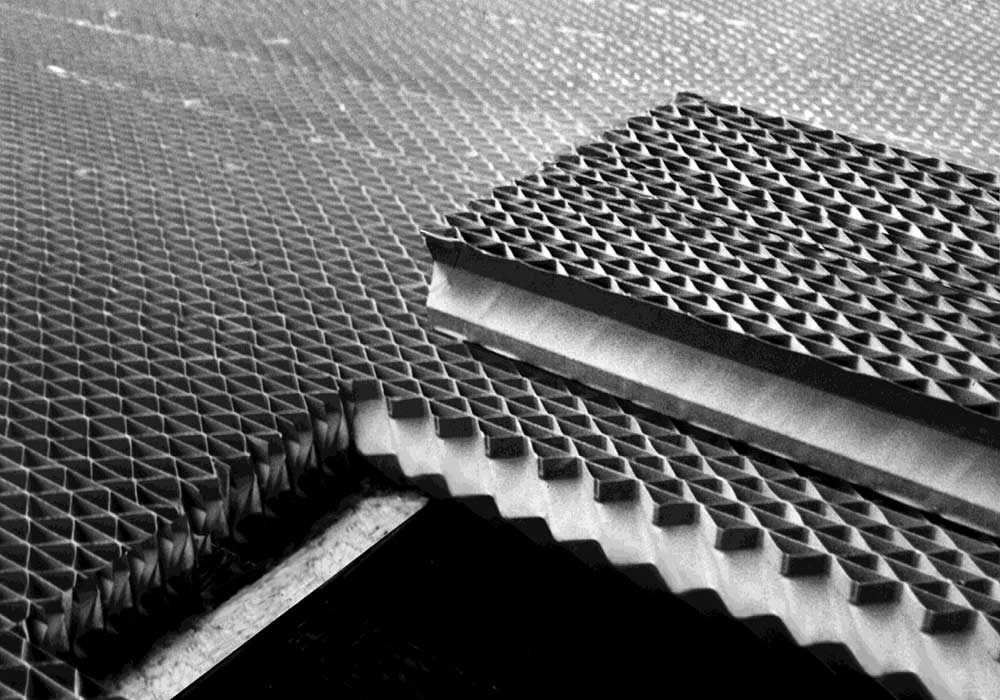

Marley developed the first cellular drift eliminator in the 1970s when eliminator designs were primarily ineffective blade type configurations.

Marley patented the XCEL generation of eliminators in the early 80s. No other eliminator could come close to XCEL eliminator’s low drift rate and low pressure drop.

Low pressure drop

Very low drift rates

Counterflow and crossflow designs

The eliminator discharge angle is important enough to warrant two separate eliminator designs—one for crossflow and one for counterflow towers. Tests show the air direction leaving the eliminator is extremely important—imperfect designs create additional work for the fan.

This means either increased fan horsepower—or reduced cooling tower performance. The crossflow version features drainage slots within the eliminator pack to insure trapped drift is returned to the wet side of the cooling tower.

Low drift rate is the primary goal of eliminator design. Low drift rates are the primary goal of eliminator designs with XCEL yielding typical drift rates of .0005% of the total gpm. Lower drift rates may be achievable depending upon tower configuration.

XCEL eliminators require little or no maintenance. If it becomes necessary to clean them, care must be taken not to physically damage the PVC eliminator packs. For loose deposits of silt, fibers, etc., a water spray can be used, provided the spray nozzle is kept moving continually and the water pressure is not excessive (recommend less than 30 psi).

With plant operation relying on your cooling tower performance, it’s important to select the parts that are among the highest quality available — Marley OEM parts.