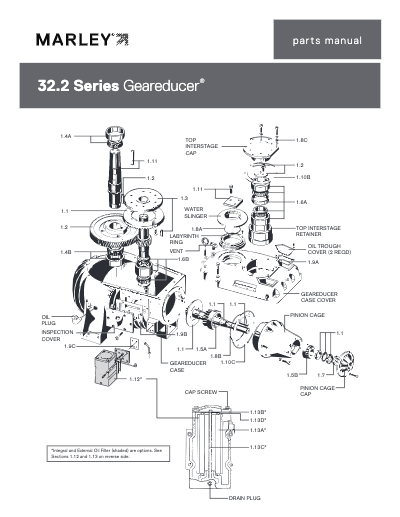

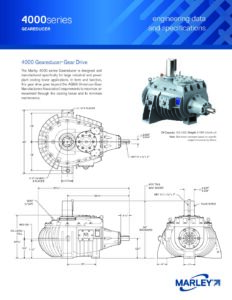

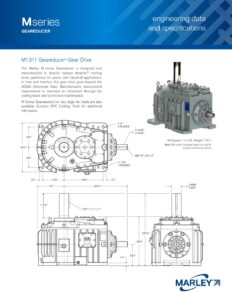

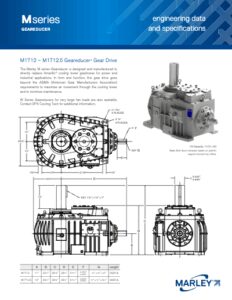

Geareducer® – Double Reduction

Cooling Tower Parts

Product Details:

Designed specifically for cooling tower duty

Designed to meet or exceed the requirements of CTI Std. 111 and AGMA standards

Minimum L10A service life of 100,000 hours on both input and output shafts

Long-life lip-type oil seal at input shaft

Output shaft sealed with a maintenance-free labyrinth ring

Timken tapered roller bearings

Two-stage (spiral bevel/helical) gear reduction for efficient power transmission

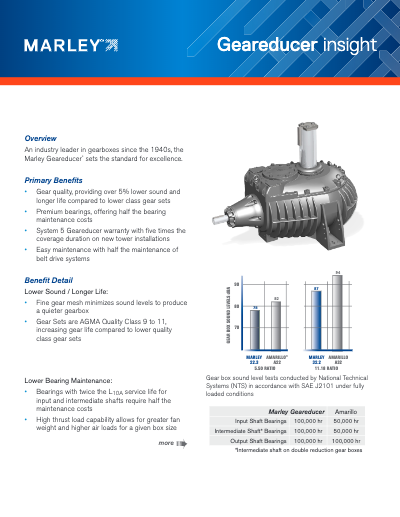

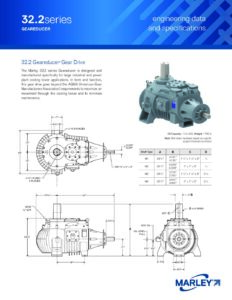

Marley industrial Geareducers are manufactured and designed specifically for cooling towers in large industrial and power plant applications. In shape and function, their design goes beyond normal AGMA requirements—both to maximize air movement through the tower, and to minimize the impact of maintenance.

Given these requirements, many manufacturers of mechanical equipment provide acceptable speed reducers. Designed for more forgiving commercial applications, these units are often unprepared for the rigors and peculiarities of cooling tower service, such as the corrosive effects of operation (often intermittent) within an exceedingly humid environment. As a result, both the life expectancy of these commercial speed reducers— and the thermal performance of the cooling towers on which they are installed often suffer.

Marley is the only major manufacturer whose Geareducers are designed uniquely for cooling tower service. And, since we warrant not only the Geareducer, but the thermal performance of the cooling towers on which they operate as well, development, design, and manufacture are taken very seriously. This has resulted in an unequalled history of trouble-free operation.