Marley MC Fluid Cooler

Home / Library / Marley MC Fluid Cooler

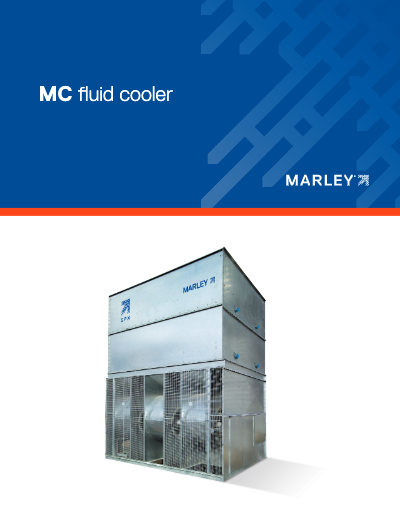

Marley MC Fluid Cooler

Brochures

The Marley MC steel forced draft counterflow fluid cooler is the ideal solution for sound- and space-sensitive applications.Available Document Languages