Search Results: "results/search&keywords=oil/P20/page/2/" | 79 results

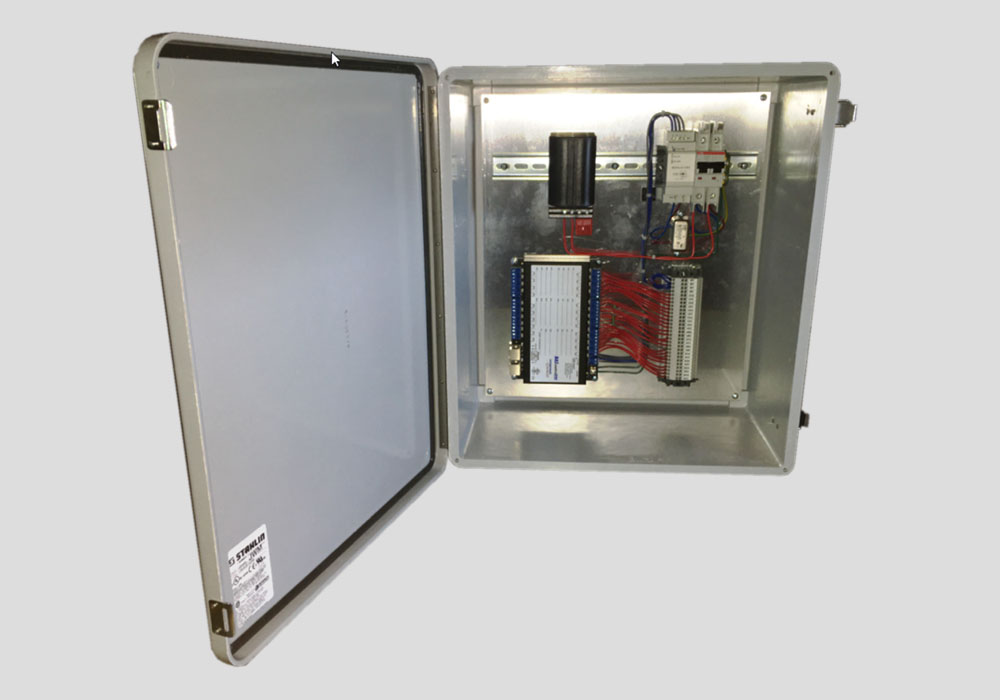

Marley CoolBoost Opti FC Control Panel

Tools, ControlsMarley Round Hybrid Plume Abatement

Products, Cooling TowersSPX Announces Acquisition of Cincinnati Fan to HVAC Global Cooling Platform

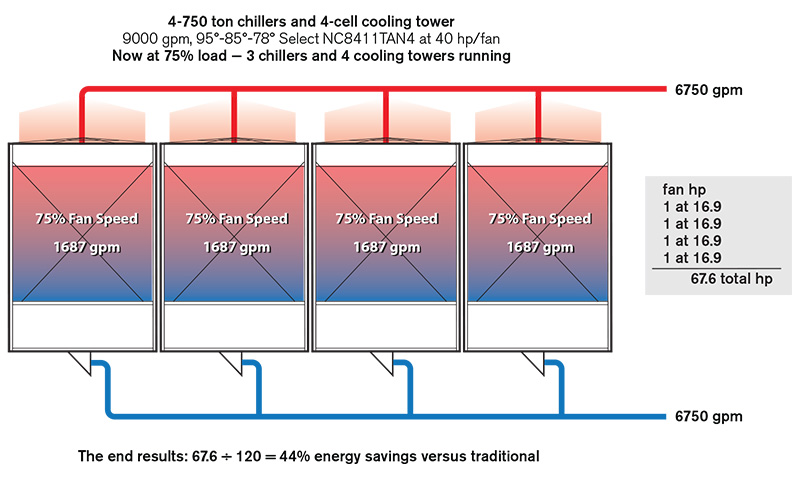

Keep It Cool News CenterVariable Flow Over Cooling Towers

About, Cooling TowersFactory Assembled Cooling Towers for Power and Industrial Applications

Brochures, LibraryPros and Cons of Cooling Tower Power Transmission Technologies

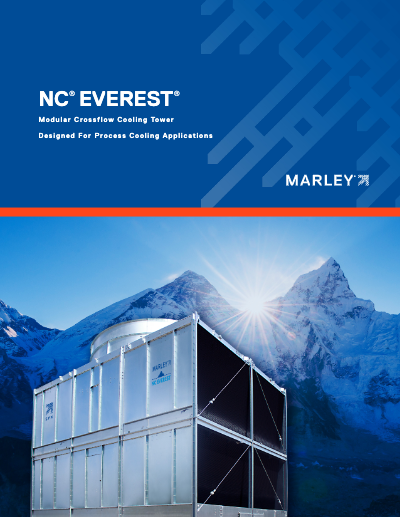

Keep It Cool News CenterMarley NC Everest – Heavy Industrial Applications

Brochures, LibrarySPX Cooling Tech to Highlight Aftermarket Cooling Tower Components and Training at Mech

Keep It Cool News CenterNew, Higher Capacity Marley MD Everest Modular Counterflow Cooling Tower Allows Process…

Keep It Cool News CenterEconomics Can Be Cool: Economic Analysis Is Critical for Cooling Tower Upgrades

Expert Opinion Whitepapers, News Keep It Cool News CenterSPX Announces Purchase of SGS Refrigeration Inc.

Keep It Cool News CenterMarley NC Everest Cooling Tower Named 2019 Environmental Leader Product of the Year

Keep It Cool News CenterMarley Insight – Safety Process

Library, White PapersOperating Cooling Towers in Freezing Weather

Library, White Papers