Cooling Tower Videos

301L vs 304 Stainless Steel

The type of steel used in the construction of your cooling tower makes a difference. In this video, we’ll discuss the advantages of using 301L stainless steel in your Marley cooling tower.

Marley® Geareducer® Cooling Tower Gearbox Oil Change

How do I change my cooling tower’s gearbox oil? The process of changing the oil in your Marley Geareducer cooling tower gearbox is straightforward – watch a Marley expert demonstrate in this video.

Cooling Tower Gear Drives Vs. Belt Drives

Some cooling towers power their fans with belt drives, and some use gear drives. But which is better for your application? In this video, we discuss the benefits of using a Marley Geareducer gear drive over a belt drive in your cooling tower.

Marley NCWD Cooling Tower Lift

The NCWD is an innovative, patented factory assembled hybrid cooling tower designed specifically for plume reduction. Watch as this NCWD is lifted in London, England.

Marley MBX EZ Pack Cooling Tower Fill

The MBX EZ Pack fill’s contractor-friendly fill design makes installation fast and easy without requiring major tower modifications.

Marley MD Everest Cooling Tower Assembly

The MD Everest Cooling Tower is uniquely suited for applications with higher cooling demands, including data centers, district energy complexes, health science campuses and industrial complexes. Watch as a new Marley MD Everest modular cooling tower is assembled in this video.

Marley® M Series Geareducer® Installation

When this customer’s gearboxes started to experience vibration and gear damage, they called in Marley for reinforcements. Watch how easily the old gearboxes were replaced with Marley gear drives in this video.

Marley® Cooling Tower Air Inlet Screens

If your cooling tower is experiencing debris buildup or fill clogging, Marley air inlet screens are one solution. Watch as we discuss the advantages of using air inlet screens on your cooling tower.

Marley Parts Vodcast 1 of 3: Geareducer

Jerome Jennings from Marley / SPX Cooling Tech. explains the benefits of using a genuine Marley Geareducer gearbox (Marley Parts Vodcast Part 1 of 3).

Marley Parts Vodcast 2 of 3: Driveshafts

Jerome Jennings from Marley / SPX Cooling Technologies explains the benefits of using a genuine Marley driveshaft (Marley Parts Vodcast Part 2 of 3).

Marley Parts Vodcast 3 of 3: Fan Blades

Jerome Jennings from Marley / SPX Cooling Technologies explains the benefits of using genuine Marley Fan Blades (Marley Parts Vodcast Part 3 of 3).

Marley Cooling Tower Bearing Lubrication

It’s important to properly maintain your Marley cooling tower bearings. Watch as a Marley expert provides some helpful tips for making bearing lubrication easy.

Marley NS Cooling Tower Spray System Overview

Marley NS counterflow nozzles develop uniform water distribution over a wide range of operating water pressures, and NS counterflow nozzles have no internal parts or narrow passageways to get clogged with debris.

Marley Geareducer Rebuild and Repair

Whether you have questions on Marley Geareducer operation and maintenance, need components to perform a repair yourself, or want to send your unit back to us for the highest level of care, SPX has the solution.

Marley ST Nozzle and Cup System

The Marley Spiral Target nozzle and cup system is an injection molded polypropylene unit consisting of two parts — the main body with integral target diffuser and a snap-on insert or orifice cap. Watch here to learn more.

Marley MH Fluid Cooler

The popular Marley MH Fluid Cooler line has expanded to include additional models, all capable of incorporating copper coils for increased thermal capacity. Watch a quick product overview here.

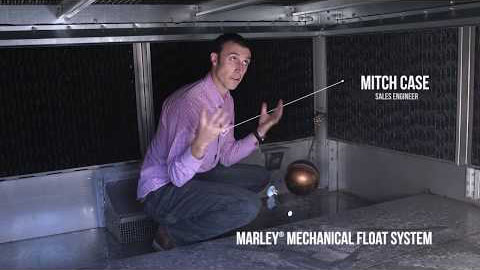

Marley Cooling Tower Mechanical Float System

What are the advantages to a Marley Mechanical Float System? Why would your cooling tower benefit from a float system? Learn more by watching.

Marley MD Cooling Tower Overview

The Marley MD is a factory-assembled, counterflow cooling tower. For many HVAC and light industrial applications, this design requires less plan area and offers greater site placement flexibility than a comparable crossflow cooling tower.

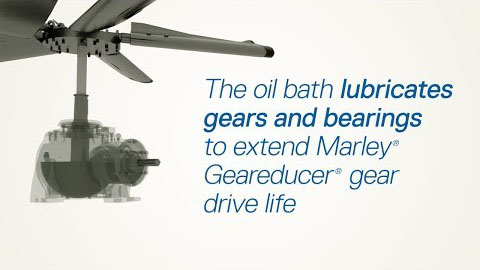

Marley Geareducer® Gearbox Overview

The reliability of the Geareducer comes from more than 100,000 units of experience, and from Marley’s attention to exacting quality standards of design and manufacturing. Today, every Marley Geareducer is tested under load at our factory. Then, it’s inspected and adjusted before shipment.

Marley Cooling Tower Maintenance

Diagnosing maintenance issues often begins with inspection of mechanical equipment and components subject to wear and tear – for example, motors, gearboxes or belt drives.

Page 3 of 5