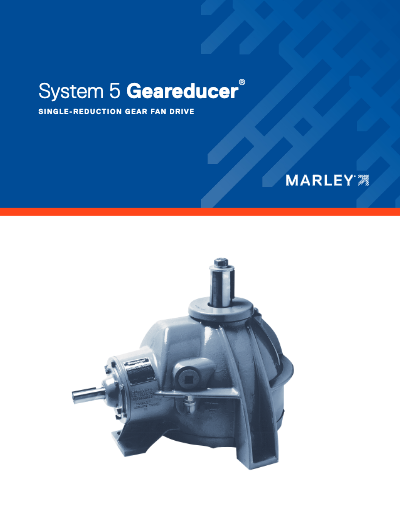

Geareducer® – Single Reduction

Cooling Tower Parts

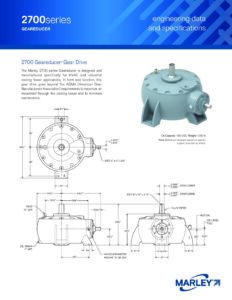

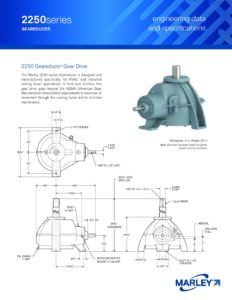

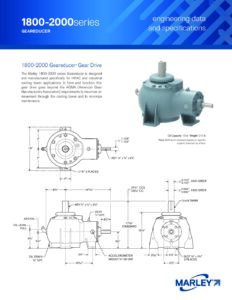

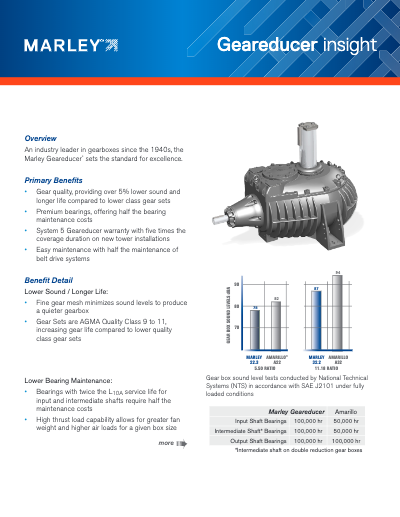

The reliability of the Geareducer comes from more than 100,000 units of experience, and from Marley’s attention to exacting quality standards of design and manufacturing. Today, every Marley Geareducer is tested under load at our factory. Then, it’s inspected and adjusted before shipment.

Marley has always known that outstanding Geareducer engineering is only as good as the lubricant that protects it. That’s why we took the next step and filled every System 5 Geareducer with Marley Gearlube™ lubricant.

In addition, Marley has made several improvements in the System 5 Geareducer to take advantage of the extraordinary lubricating properties of Gearlube. The new 1800, 2000, 2200, 2400 and 2800 Geareducer models will utilize a long-life lip-type oil seal at input shaft for extended service life.

We’ve equipped it with a magnet in the sump to trap metal particles generated during initial break-in period.